Tap test - What you need to pay attention to!

Have you ever been tempted by cheap tools from the supermarket, only to find yourself frustrated with the poor results when working on a DIY project? Talent and care aren't enough when it comes to craft; you also need reliable tools. Especially when it comes to thread cutting, precision and quality are crucial. But how can I identify high-quality thread cutting tools? What should I look for, and what production steps make a good screw tap? To help you be well-equipped in the future and maintain your passion for craftsmanship, we'll explain in this article 10 characteristics to help you conduct a quality thread cutting tools.

Thread Cutting Tools Test: 10 Characteristics of a Quality Thread Cutting Tool

We've compiled a list of features to help you perform a thread cutting tool test. Here's what to look out for:

1. High-quality Raw Material

The material from which the thread cutting tool is made forms the basis of the tool's properties and is, therefore, vital. Good screw taps are made of high-speed steel. This steel possesses all the desired properties: it's easy to machine and grind, doesn't deform, can withstand high loads, and exhibits good wear behavior. The correct alloy composition for your thread cutting tool test is especially crucial.

Quality taps made from high-speed steel are identified by the abbreviation HSS, which stands for High-Speed Steel. The HSSE label indicates high-speed steel with a high cobalt content – which is particularly hard and resistant to tempering. HSSE-PM is produced using a powder metallurgy process, allowing higher alloy levels.

You should avoid thread cutting tools made from tool steels (like tungsten-carbide steels). These fail the thread cutting test immediately.

2. Uniform Hardness Distribution

Hardness is an essential feature of a good screw tap, but it must also be evenly distributed. To achieve this, quality srew taps are tempered multiple times after hardening, reheated and cooled again. This process takes time but ensures a uniform hardness structure and prevents material stresses. So, don't overlook this point during your thread cutting test.

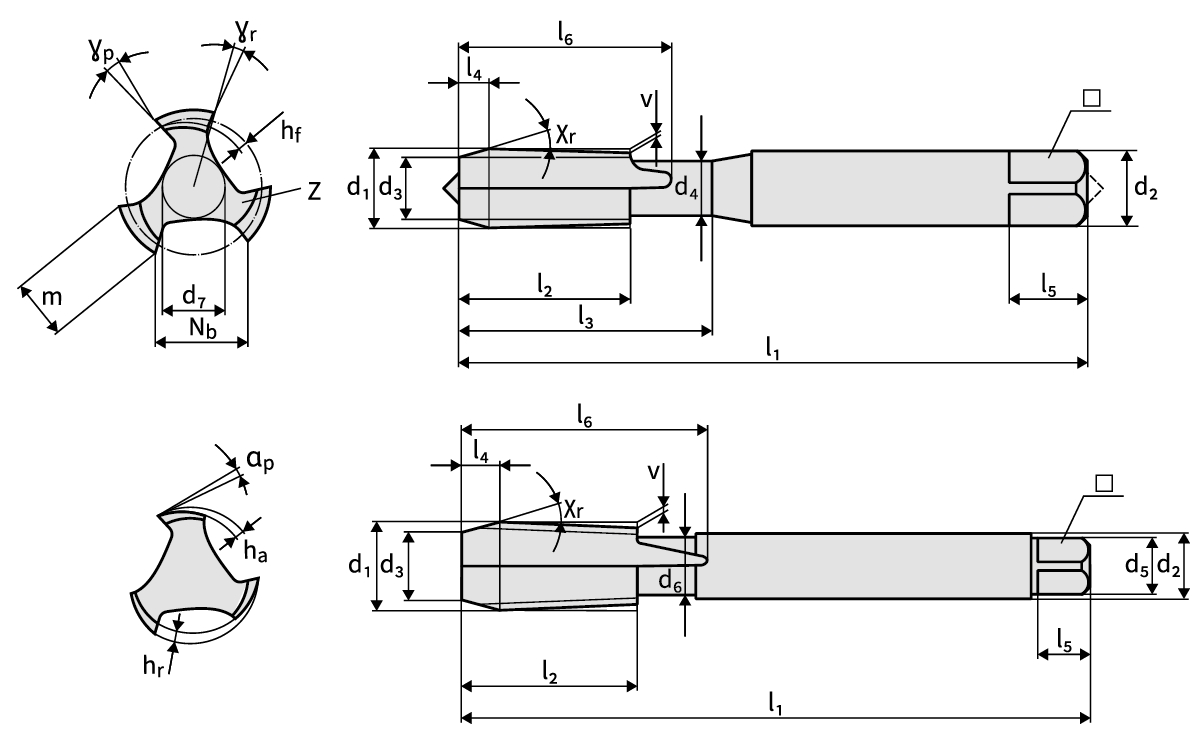

3. Good Grinding Pattern

As little friction as possible should arise during the thread cutting process. Therefore, a good grinding pattern, meaning a smooth surface, is an essential feature of a quality tap in the thread cutting tools test. This allows the tool to glide smoothly through the material and effectively transport the resulting chip via the flutes.

An impeccable grinding pattern includes the cutting angle and the radial clearance angle, which determine the sharpness of the tap. These must be tailored to the material being worked with. Good screw taps, in the thread cutting tools test, have uniform cutting angles, ensuring an even load on the cutting edges or cutting teeth. As a result, quality screw taps don't wear out quickly and deliver excellent cutting results.

4. Carefully Ground Edges

Mass production often prioritizes speed. However, rushing can have detrimental effects on the screw tap. If the grinding is done too quickly, it generates undesirably high temperatures, potentially causing a loss of hardness. Quality screw taps are produced with the necessary care and attention to prevent excessive temperature development.

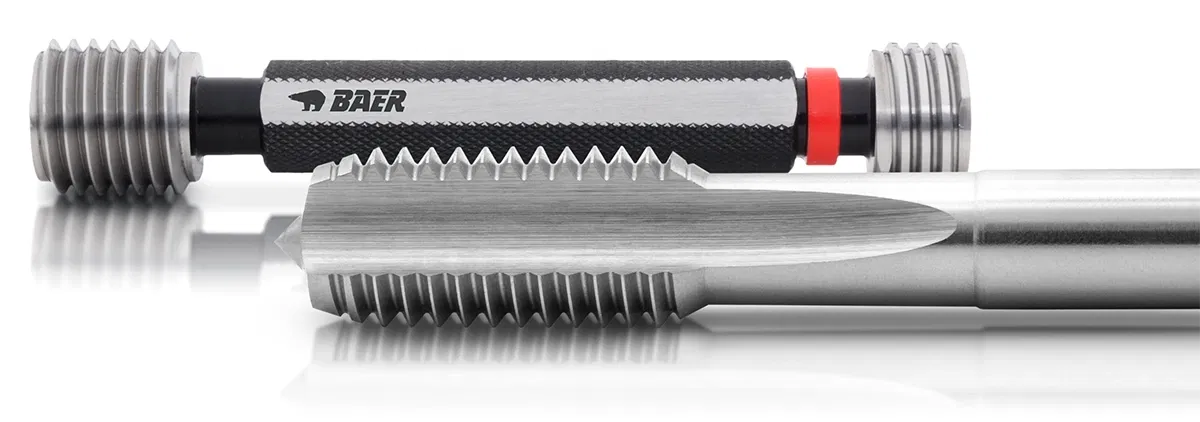

5. Gauge Compliance

There's a reason for thread standards. Threads that meet these standards are true to gauge, as they can be checked using designated thread gauges. Why is gauge compliance important for the cut thread? Only threads that conform to standards are durable, safe, and have the expected properties. Quality taps produce gauge-compliant threads in the desired size and without pitch errors in the thread cutting tools test, ensuring reliability. If you want to learn more about this topic, we recommend this blog post!

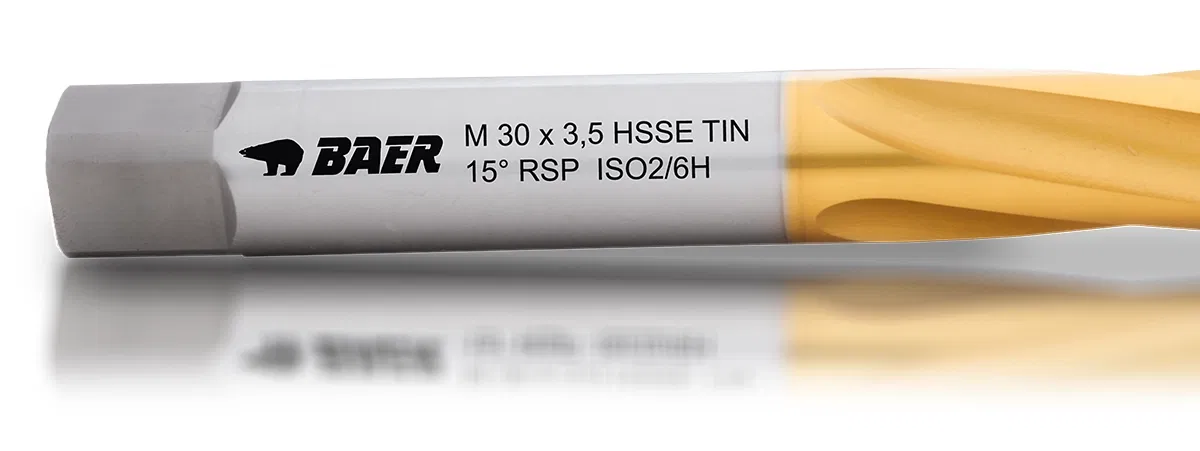

6. Informative Marking

As manufacturers of taps, we take pride in our products and print our name on the tools. Especially when ordering cheap drills online, this detail often goes missing. Should something go wrong or if you have questions, you won't know who to contact. In addition to the manufacturer's mark, quality screw taps should also display other markings. Information on material quality, thread dimensions, and thread tolerance are signs of a good thread cutting tool in the test.

7. Optimally Prepared Cutting Edges

Often, edge preparation is a well-guarded company secret – and for a good reason. It's an essential quality feature of good screw taps. Micro-treated cutting edges ensure uniform cutting performance and a long tool lifespan in the thread cutting tool test. They are a clear sign of a quality tap.

8. Packaging

When ordering online, the first indication of quality is the product's packaging. Is the tool safely packaged? If not, it should be sent back immediately according to our thread cutting tools test criteria. After all, a tap is a thread cutting tool that relies on the condition of its cutting edges. Improper storage and poor transport protection can cause the cutting edges to chip, making the tool dull or entirely unusable.

9. Brand Name

Of course, even well-known manufacturers sometimes compromise on quality. However, it's generally a good sign if you buy good taps from renowned traditional brands. Not only do you have a clear point of contact if there are any problems, but you can also interact with other customers about specific products, view ratings, or consult third-party thread cutting tools tests, significantly reducing your buyer's risk.

10. Price

Price is also a decent indicator in the thread cutting tool test of receiving a quality tap. While there are overpriced products on the market, a price that's too low is a sure sign that the manufacturer didn't adhere to the highest quality standards and, therefore, couldn't produce quality screw taps. All the mentioned points take time and effort, which inevitably reflects in the price. If you suspect that such a low price can't offer a good screw tap in the thread cutting test, you're probably right.

Bonus Point: Coating

A good thread cutting tool doesn't necessarily need a coating for the test, so this isn't a clear quality criterion. However, coatings can be beneficial, improving tool life time, increasing hardness, minimizing friction, and enabling higher cutting speeds. The coating is applied as a thin layer on the finished screw tap. Depending on the application, there are different variants and compositions that enhance specific properties of the tap.

Thread cutting tools with top test results can also be found in the online shop of Tap Manufacturer BAER. Check it out and let our wide range of high-quality products convince you!