The Cross Threaded Spindle: Back and Forth for Perfect Spooling

Have you ever seen cross-thread spindles (also known as reversing spindles)? Maybe you don't really know! Because at first glance, cross-thread spindles are not immediately recognizable as threaded spindles. Sounds mysterious? Then wait and see. This special form of motion thread has a number of features that you may not otherwise recognize from thread technology.

The cross-thread spindle is an interesting example of what is possible with threads when resourceful engineers are at work and think outside the box. The cross thread is definitely worth a closer look. Are you curious? Then follow us on our search for clues. But be careful, it could get wet and stormy!

What is a cross thread?

The cross thread is a real specialist among thread types. Not an all-rounder that can be used anywhere, but a professional with a narrowly defined field of application. This is due to its special design.

These are the special features of the cross thread

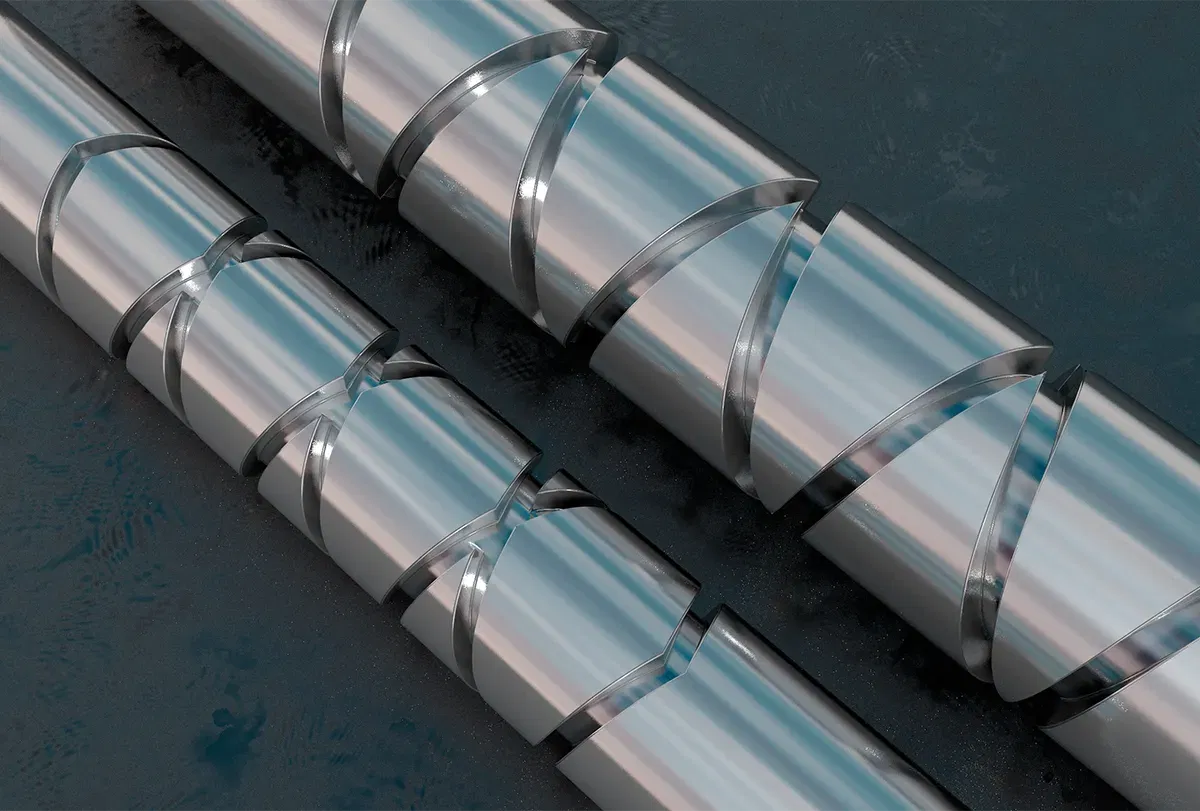

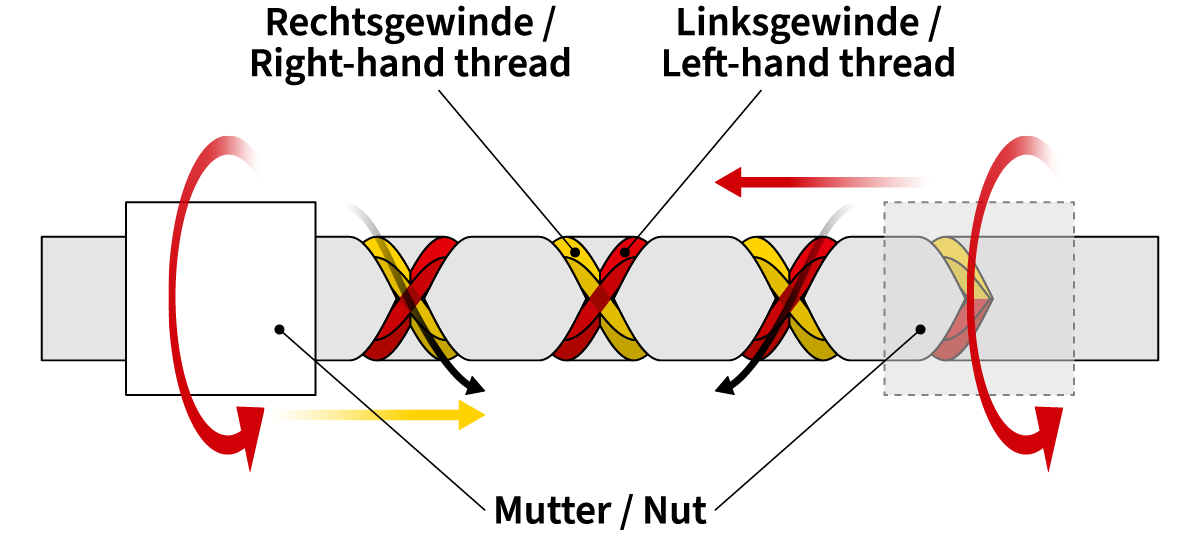

A cross thread is so different in appearance from other thread types that it cannot be mistaken for another type of thread. This is because there are two threads on the spindle. In itself, this is nothing unusual, were it not for the direction of rotation. The threads are in fact a left-hand thread and a right-hand thread. Consequently, the threads do not run parallel to each other, but cross at regular intervals. And that's where the name comes from - cross threads.

Is there a standard for cross threads?

Cross-thread spindles, cross lead screws and reversing spindles are very special components that are usually produced by the manufacturer as a custom-made product directly according to the customer's specifications or a drawing. There are no standard dimensions or overarching standards for this type of thread; instead, the size and material are tailored precisely to the application purpose.

How the cross-thread spindle works

But what exactly makes the cross-threaded spindle so special? To understand this, we first need to go back to a common type of thread. Imagine a standard screw and the matching nut. If you want to turn the nut onto the screw, rotate it to the right. To unscrew the nut again, however, you must rotate it in the opposite direction. To achieve the desired effect, you must therefore change the direction of rotation.

The cross-threaded spindle makes it possible to achieve the same goal without changing the direction of rotation. If we stay with our example, the nut would change direction independently and reverse at the end of the screw to return to its starting point. It rotates in the same direction the whole time.

This works because the two threads at the end of the cross-threaded spindle do not run out, but are connected to each other. A driver that is perfectly matched to the cross thread therefore moves to the end of the spindle and automatically switches to the other thread, which moves it in the other direction again.

While the German term "Kreuzgewindespindel" focuses very much on the striking visual feature of the thread, the English term sums up the function better: it refers to self-reversing spindles.

From offshore winches to textile production: cross-thread spindles are used here

The basic principle is clear, but we still don't know what it's actually good for. So let's go into practice and see where we can find the cross-threaded spindles!

This movement is particularly well-suited for the cross thread

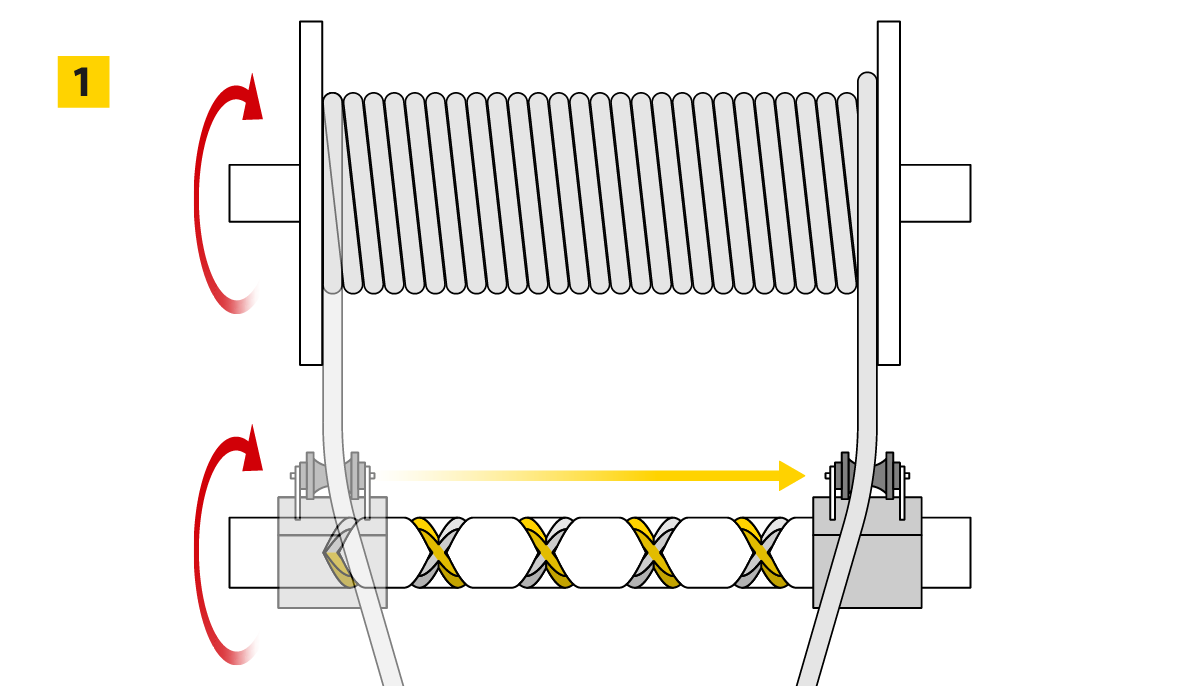

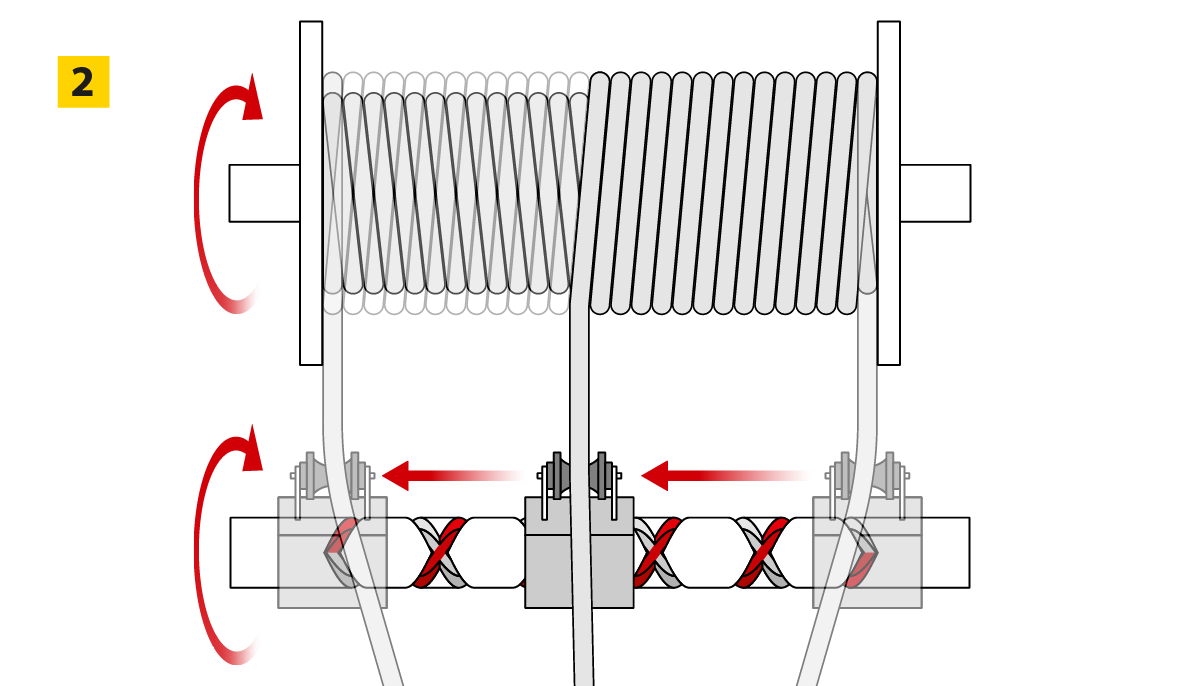

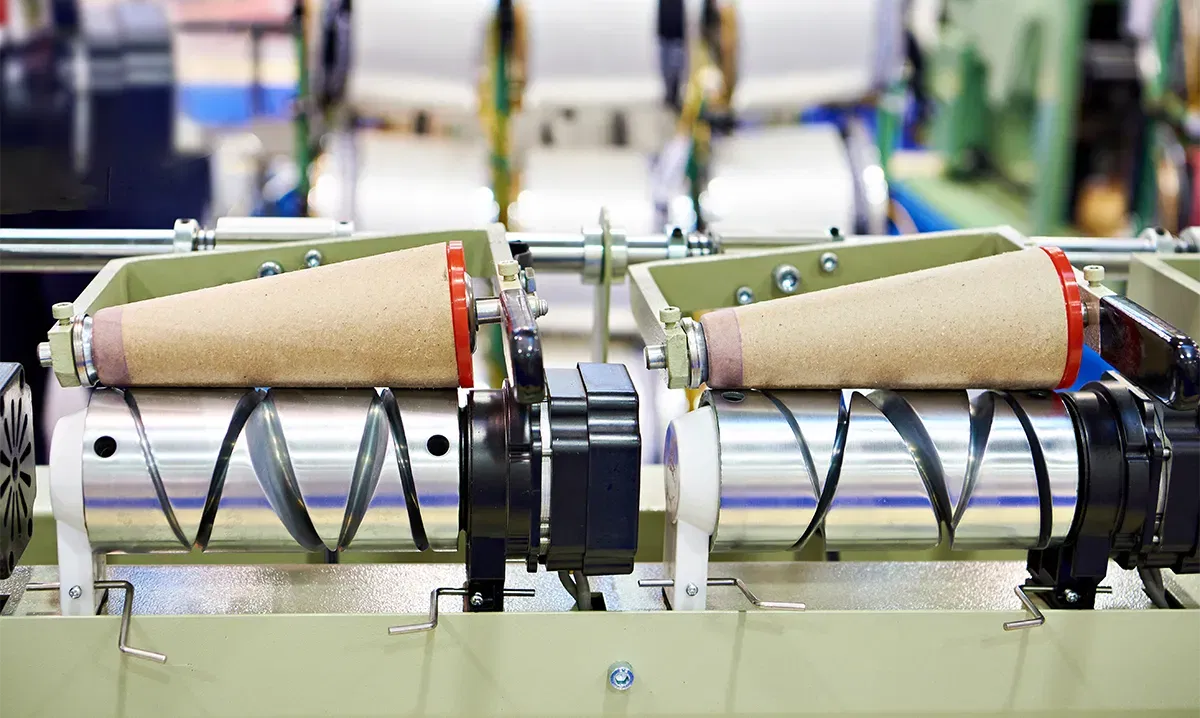

The cross-threaded spindle enables a smooth movement between two points that reverses automatically without the need to change the direction of rotation. This makes it ideal for any type of spooling device - whether ropes and cables in offshore winches or yarns in the textile industry.

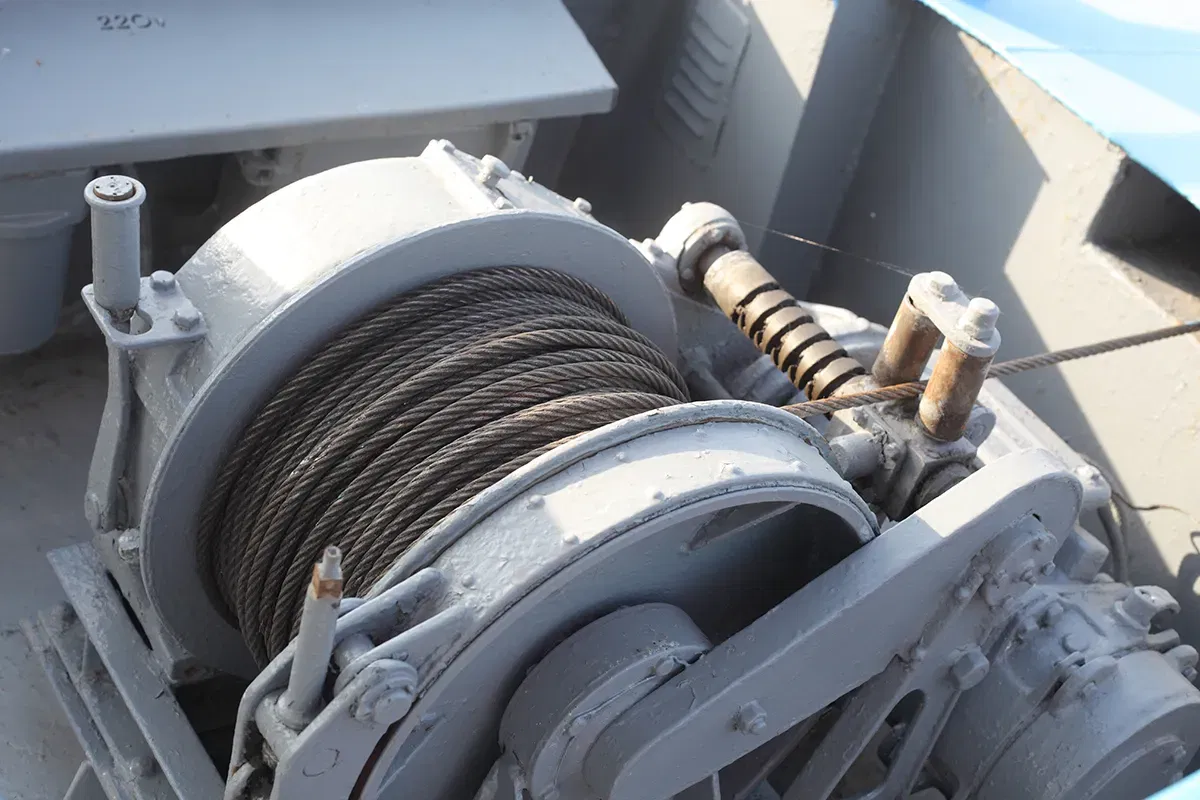

Cross-thread spindles in the offshore industry

But why is the spooling of ropes and cables such a big issue in the offshore industry that there is a dedicated thread type for this task? It's because of the enormous values behind every single device and component in this industry.

If you roll up the cable criss-cross in your cable drum, this is not good for the material either. But if damage occurs in the long term, then you simply replace the cable. And now imagine that this cable would cost you several 100,000 $. The motivation to be a little tidier when rolling up in future would be many times greater, wouldn't it?

The cross-threaded spindle therefore ensures that the huge and expensive cables are wound cleanly and absolutely evenly onto the huge and expensive winches. The automatic change of direction means that hardly any human intervention is required and the mechanism requires as few elements as possible that would be susceptible to faults or breakage in rough seas.

Other applications for the cross-thread spindle

But even winding is also a desirable effect in other areas. Yarn in the textile industry is generally not as expensive as an offshore cable, but unclean winding can also cause major economic damage here. And in areas such as crane construction, where the clean routing of a cable is relevant for safety reasons, a cross thread can also be used sensibly.

And we've saved the best for last. There are actually already cable reels with reversing spindles! However, these are not designed to make your DIY work at home more convenient, but are used in dangerous and difficult-to-navigate environments to enable cables to be used safely.

Cutting a cross thread yourself - that will be difficult. But you can find the tools and accessories you need for any other type of thread in the BAER online store! Take a look around and see for yourself. Our friendly customer service will be happy to answer any questions you may have.