The most important materials and their properties

When machining threads, there is no getting around a little material science. After all, the first step in thread cutting is to select the right tap. And you can't find one if you don't know exactly what material you're dealing with.

But don't worry, it is not necessary to know the exact composition of a nickel-cobalt alloy with all its material properties to the nearest hundredth. An overview of the basics is usually sufficient and you can of course get this from us.

In our online store, you will also find detailed information on the original material and the material groups that can be processed with a tool on each product page. So be sure to take a look there too!

The materials are categorized as follows

Materials can be categorized in different ways. Materials with similar properties or compositions are usually grouped together.

Each material is assigned a material number so that it can always be clearly identified. At the same time, there are other standardized designations and material abbreviations for steels, which follow a fixed system using a combination of numbers and letters to represent key properties of the material.

General subdivision

A distinction is first made between metals and non-metals. The latter group can then be divided into natural materials, which can be organic (e.g. wood) or mineral (e.g. graphite), and artificial materials such as plastics, glass or ceramics. And then, of course, there are composites, which consist of several different basic materials. These include reinforced plastics or hard metals.

Subdivision of metals

Does that sound complicated? Then you'll be pleased to know that we can focus primarily on the metal group when cutting threads. Although threads can also be created in plastics, this is the exception rather than the rule. You can find a good overview of all materials for thread cutting here.

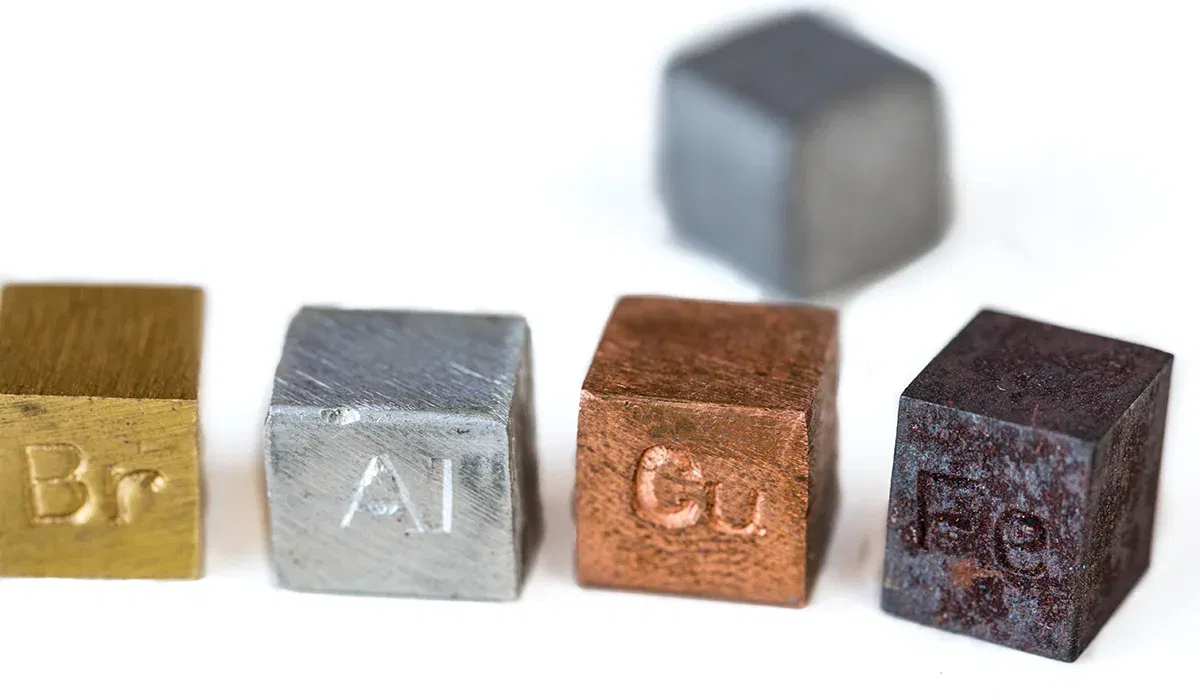

Metals can be further divided into two subgroups: Ferrous materials and non-ferrous metals.

Ferrous materials

Even in the subgroup of ferrous materials, we have not yet arrived at the smallest unit. A distinction is made here between steels and cast iron materials. The decisive factor is the carbon content, which is a maximum of 2 % for steel, but higher for cast iron.

Steel is characterized above all by its high strength and can be cold or hot formed. Steel grades with specific properties are literally a dime a dozen - several thousand in fact. These include stainless steel, tool steel and free-cutting steel, which is particularly suitable for machining processes such as tapping.

Cast iron cannot be plastically formed, but it is easy to cast. Cast iron materials are therefore often used for complex shapes that are difficult to produce in any other way.

Non-ferrous metals (NF metals)

The importance of iron becomes clear when we realize that the unifying characteristic of the second group of metals is in fact simply the fact that it is not iron. This group includes materials such as copper, zinc, lead, aluminum, magnesium, nickel or titanium and their respective alloys.

Based on their density, non-ferrous metals can be divided into heavy metals and light metals. Heavy metals such as copper or chromium are often used for specific applications due to their specific properties. For example, copper is used in power lines due to its electrical conductivity.

Light metals, on the other hand, are actually characterized by their low weight and are therefore often used in vehicle construction in order to achieve lower fuel consumption by reducing mass.

A material can have these properties

The properties of a material can be determined in very different ways. We can look at the physical properties, mechanical properties, chemical or manufacturing properties. To keep this overview as simple as possible, we will limit ourselves to a few characteristics of materials that are of interest in thread cutting.

Toughness and brittleness

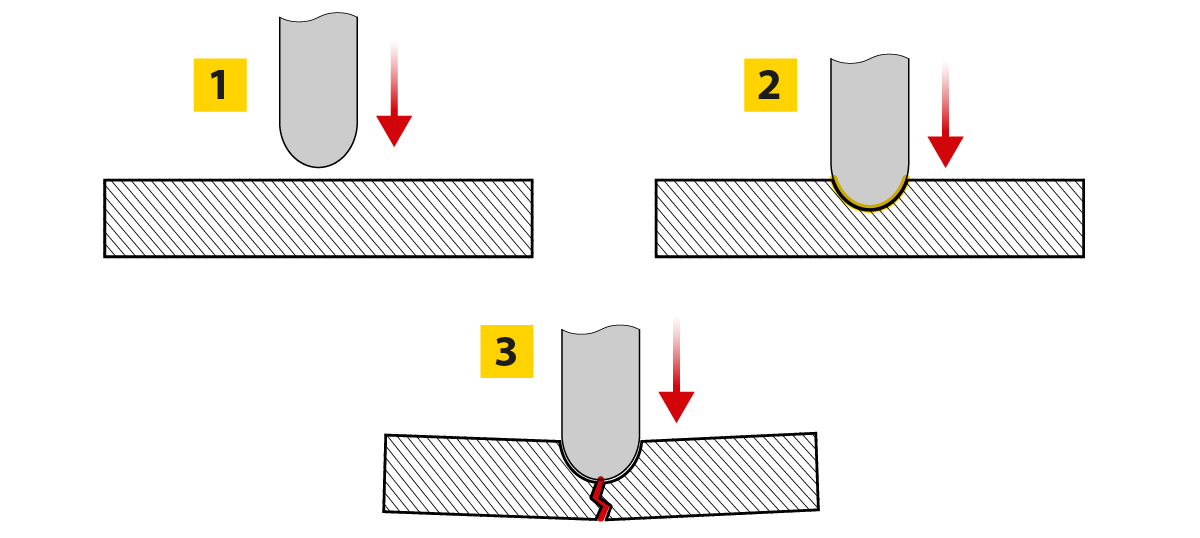

On a mechanical level, we are interested in how tough or brittle a material is. These two terms describe how much mechanical energy a material can absorb during plastic deformation.

Although a tough material such as structural steel can deform under heavy loads, it will not break or crack. In contrast, brittle materials such as glass or ceramics can only absorb a small amount of energy and break very quickly. There are also brittle types of metal, such as cast iron. Brittleness can also occur as an undesirable effect in improper production processes, e.g. when steels are hardened incorrectly.

Tensile strength

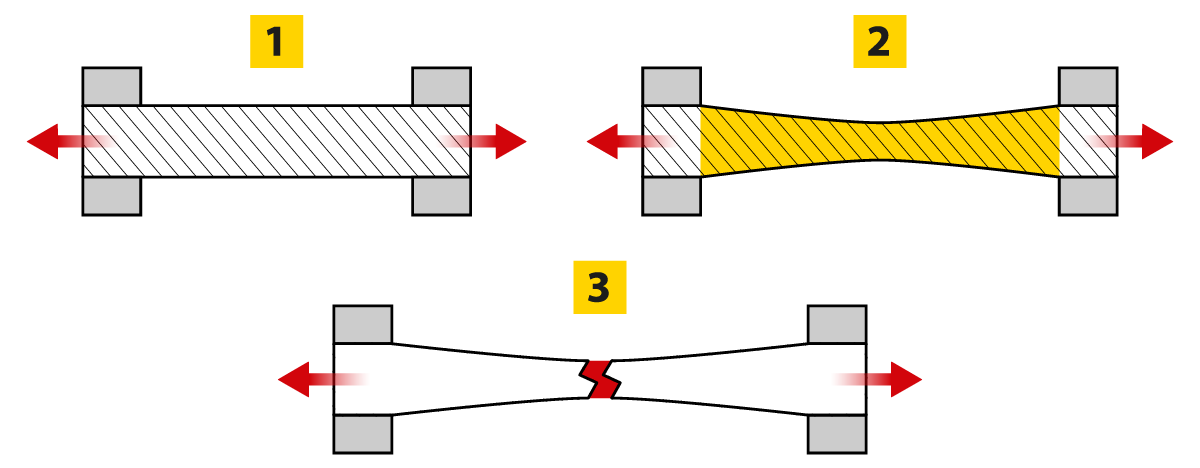

The tensile strength indicates how much tensile stress a material can withstand. To illustrate this, imagine a firmly anchored metal rod that is being pulled. Initially, the rod will stretch elastically (i.e. not permanently), then plastic (i.e. permanent) deformation will occur and at some point it will break completely. This allows important conclusions to be drawn about the stability of bolted connections.

Plastic deformation is also known as stretching. The greatest possible tensile stress before the material is stretched is the yield point. The tensile force applied at this point is the tensile strength of the material. Both the yield strength and the tensile strength have the unit N/mm².

Machinability

In the area of manufacturing properties, we are primarily interested in the machinability of a material when machining threads. This indicates how well a material can be machined using cutting processes such as tapping. Machinability is determined by several criteria, above all:

- the quality of the surface of the components after machining

- the chip conditions (the resulting chip should not hinder the production process)

- the cutting force acting on the tool

- the service life of the tool used

Poor machinability can be partially compensated for by reducing the cutting speed or using a suitable cooling lubricant. Depending on their microstructure, steels and cast iron are often easy to machine, but tough and very hard materials are difficult to machine.

How do I find the right tap for my material?

Hopefully you now know a little more about the material your component is made of. The only question is how to find the right tools - i.e. taps. We offer you simple solutions in our BAER Shop. Use the BAER Toolfinder on the start page and select the material you want to work with under 'Application'. You will then see a overview of all the tools that are suitable for this material. The respective product page for an article also always contains detailed information.

Do you have any further questions about materials or any other concerns? Then use the contact form to get in touch with our customer service. We will be happy to help you!