Which machine do I need for thread cutting?

Are you new to thread machining or looking for ways to optimize your work process? Then you may be wondering which device is best suited to thread cutting. Or would you prefer to cut threads without any machine support at all?

The good news is that the production of a thread can be accomplished in different ways, so you are flexible. The bad news is that you are spoiled for choice and have to make a decision. But don't worry, as always, we're here to help and provide you with all the information you need.

The following article gives you an overview of all the options you have for producing a thread with or without a machine. We will then give you a few tips to help you choose the right method for you.

Tapping by hand with the hand tap

Of course, you can also cut threads without any mechanical support – with a hand tap. Or more precisely, with three hand taps. These taps always come in a set. This means that the necessary effort is divided between several taps and is also easy to do by hand.

In addition to the tap, you also need a holder such as a tap wrench or a tool ratchet, as well as cutting paste. This method is flexible and inexpensive because you do not need any machines. Compared to machine methods, however, the manual method takes longer and you need a little dexterity. If you only want to cut threads occasionally, the hand tap is a good choice.

Cut threads with hand tools: Cordless screwdriver and hand drill

We go one step further in the direction of mechanical support with the use of hand tools such as a cordless screwdriver. Opinions differ on this method. Some claim that it is impossible to cut a clean thread with a cordless drill. Others, on the other hand, swear by it and have many successful experiences to report.

What is the problem? The human factor. Holding the device absolutely straight, not wobbling and then drilling at the right speed – things can quickly go wrong. However, if you have a steady hand and a good gut feeling, the cordless screwdriver combines flexibility with speed like no other method.

For this to work at all, however, you need a suitable bit tap with hexagonal shank that fits into the holder of your device. Alternatively, you can also work with adapters that turn a square shank on the tap into a hexagon.

Tapping with the stationary drilling machine

You can also use a bench or floor drill for thread cutting. The extent to which the human factor plays a role here depends on the model. With some, you control the feed by hand, while other machines can also be programmed. At least here you have the guarantee that the tap is perpendicular to the workpiece. This is a great advantage for a clean thread and prevents tool breakage.

You should use a machine tap and a high-quality drill chuck. Changing the tool and clamping the tool and workpiece can seem time-consuming on a day-to-day basis if you want to cut individual threads. However, the time factor quickly turns into a positive factor in series production. Drilling machines can suddenly increase efficiency enormously.

We have written down everything you need to know about stationary drilling machines, tips on purchasing them and an explanation of the different types in our blog.

Tapping machines: For professionals and all those who want to become one

Now we have finally arrived in the professional sector. A tapping machine is a machine tool that specializes in the production of threads. This means that it is excellent at this one task, but it can't do much else. If you would like to find out more about this topic, take a look at our blog.

There are various types of tapping machines that differ from each other in terms of drive and application. They can be used with a normal tap. This allows you to produce a variety of threads very quickly and precisely. Whether you need this is another question. As a DIY enthusiast, probably not – unless you are really keen on thread machining, which we could totally understand. For professionals, however, the purchase can be very worthwhile!

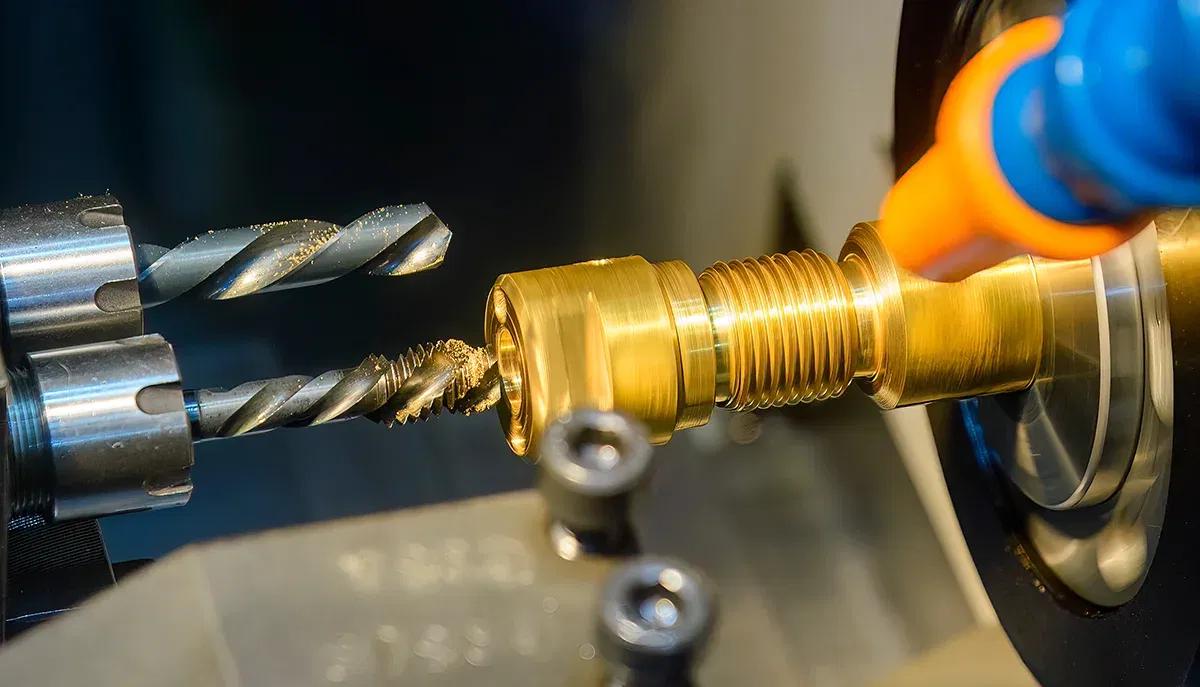

CNC machines for industry and series production

Well, whether you want to put a CNC machine in your garage is ultimately up to you. It would certainly benefit the accuracy of your threads. The gentle giants produce absolutely precise results, always reliable, always reproducible, professional quality. However, space is not the only problem.

Because before the CNC machine starts its work, it first needs to be programmed so that it registers what it is supposed to do. We have already looked at how complicated this can be here. And then, of course, there is the price. But like everywhere else, the market is changing and computer-controlled machine tools are now also being produced in small, affordable versions for the end user. Perhaps soon for thread cutting too!

Conclusion: Which machine is the right one for your thread?

You have probably already come to the same conclusion: The choice of method ultimately depends on the degree of professionalization and how much time and money you want to invest. For the occasional DIY project, taps for manual use are certainly a good starting point. Or you can try out whether working with a cordless screwdriver appeals to you and whether you can achieve good results this way. If you like to tinker a lot anyway, then a stationary drill is certainly worth buying. You can then use it to carry out numerous other jobs. However, tapping and CNC machines certainly belong in the professional sector.

No matter which version you choose, you will find the right tap in our online store. Whether with a hexagonal shank for cordless screwdrivers or with a special coating for tough applications – we have them all! And if you have any questions, you can contact our customer service team at any time by phone or via our contact form.