BAER Drill Chuck 0.2 - 16 mm | incl. taper shank arbor: MT 4 | pull-in thread: M 16 | keyless drill chuck

In stock

Express shipping available

BAER Drill Chuck 0.2 - 16 mm | incl. taper shank arbor: MT 4 | pull-in thread: M 16 | keyless drill chuck

High-precision drill chuck - Premium quality for professionals

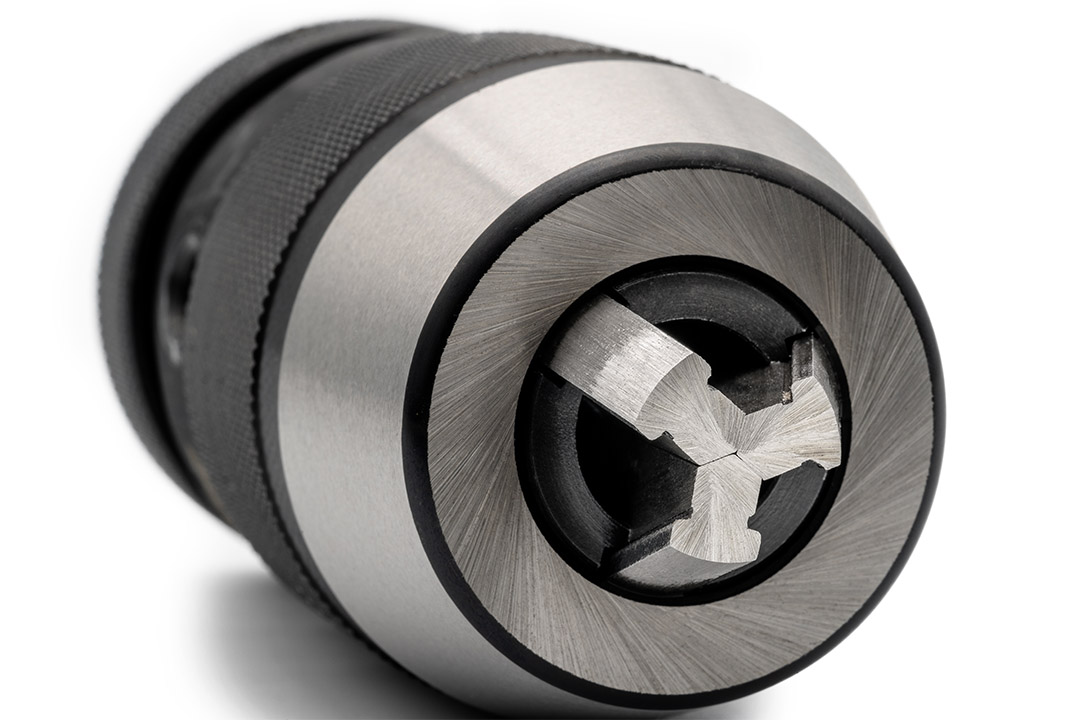

Ground from the best steel, high-precision elements, solid and stable design, ergonomic in the hand. This high-precision keyless drill chuck is a must for every craftsman. Unlike a keyed drill chuck, the keyless drill chuck can be opened and closed easily by hand. A clamping key is no longer needed. Thanks to its re-tightening characteristics, the drill bit sits firmly and securely in the drill chuck.

This self-clamping drill chuck is impressive not only because of its high clamping force, but also because of its feel and stability, as well as its long service life. The drill chuck is suitable for hammer drills, pillar drills, milling machines and lathes and is suitable for clockwise rotation.

Dimensions

| Concentricity |

0,08 mm |

|---|---|

| Weight drill chuck |

1290 g |

| Weight taper arbor |

530 g |

| Drill chuck clamping range |

0,2 - 16 mm |

| Machine mount |

MK 4 |

| Thread mount |

M 16 |

Characteristics

| Product group |

Drill chucks |

|---|---|

| Product type |

Drill chucks for standing drill machine |

Applications

The drill chuck is ideal for industrial applications in pillar drilling machines, milling machines, lathes etc. and is the perfect choice for industrial companies, metal construction companies and locksmiths.

Technical drawing

| D1 |

54 mm |

|---|---|

| L1 |

100,5 mm |

| L2 |

111,8 mm |

| L3 |

220 mm |

Safety instructions

High concentricity for precise holes and long tool life time

Precision that you not only see, but also feel. Our BAER drill chucks have a runout accuracy of 0.08 mm. Due to the high precision of the individual parts, our drill chucks have a very long service life.

Why is high concentricity important? With high concentricity, you not only get precise drilling results, but high concentricity also saves money, because the most frequent cause of premature wear on drilling tools is insufficient concentricity and the lateral forces that occur. With a poor drill chuck, your drills can break quickly. Once too much pressure is applied and the drill bit is off. These uneven forces would also quickly break the drill chuck. Avoid these mistakes and buy a drill chuck for professionals right away! Save time and money.

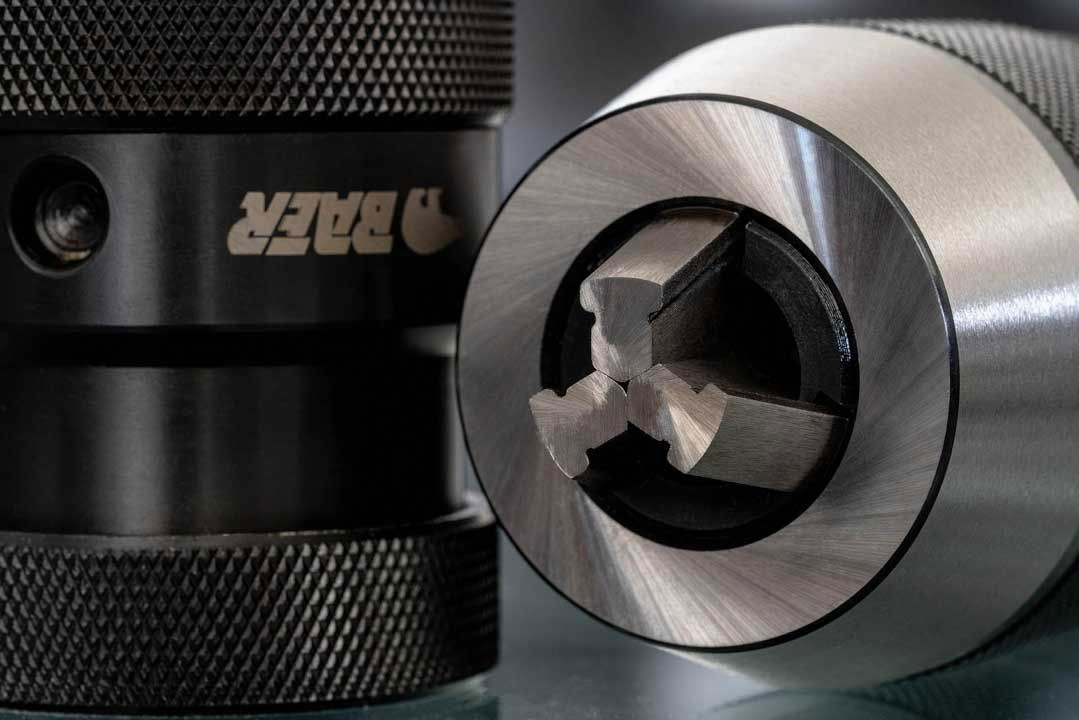

Hardened clamping jaws for a secure hold

The three clamping jaws of the drill chuck are hardened to enable high holding force and long service life. They can clamp insert tools in a centred manner and transmit high clamping forces to them. Thanks to state-of-the-art technology, the drill bit can be fixed firmly and securely with little effort and can also be changed again quickly.

Whether for craftsmen, professionals, industrial companies or DIY fans - a drill chuck that no workshop should be without.

Solid metal body for stability and performance

With its solid body, you feel the high value and quality of the drill chuck not only in your hand. In use, this drill chuck is a true all-rounder.

Thanks to the precisely processed and ground steel, this drill chuck with its durability and wear resistance can be used universally. The ergonomic design and the precisely coordinated interior are convincing all along the line.

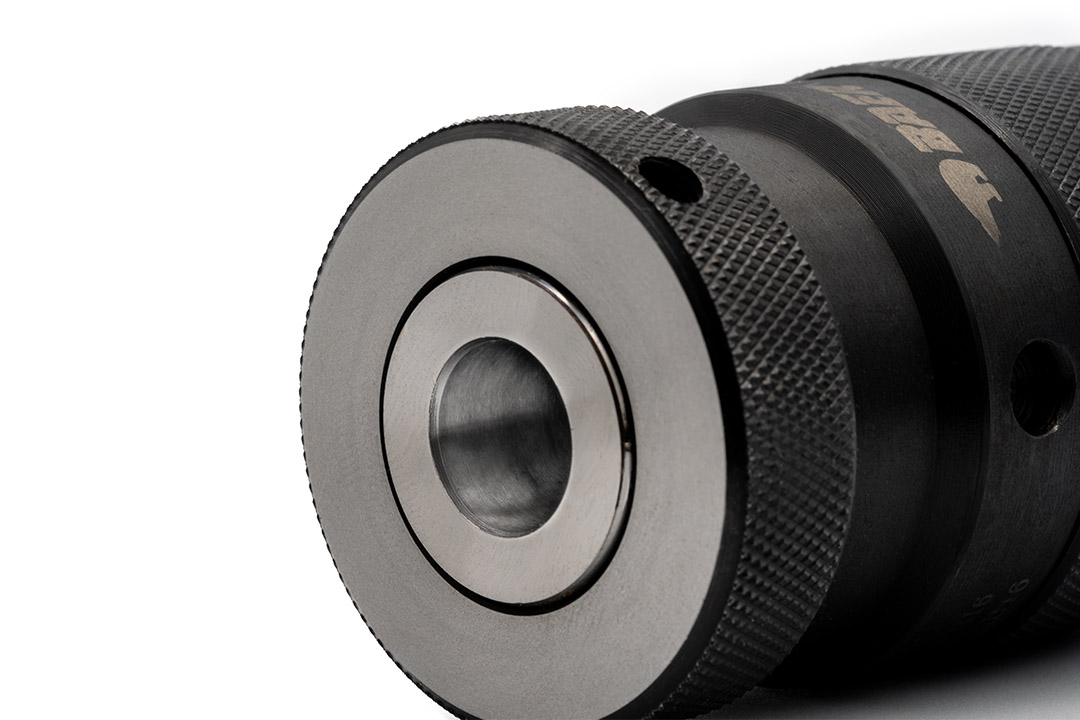

High-precision taper fitting for a strong connection

The almost tolerance-free connection between the drill chuck and taper shank arbor allows the high drive force to be transferred to the drill chuck. Only with such a precise mounting can a drill chuck achieve such a runout accuracy and long service life.

| MK0 | MK1 | MK2 | MK3 | MK4 | MK5 | MK6 | |

|---|---|---|---|---|---|---|---|

| ø A in mm | 6,40 | 9,37 | 14,53 | 19,76 | 25,91 | 37,47 | 53,75 |

| ø B in mm | 9,21 | 12,24 | 17,98 | 24,05 | 31,54 | 44,73 | 63,73 |

Always the right choice - Morse taper dimensions

With the BAER drill chuck you have already made the right choice.

Now you just have to choose the right dimension for the Morse taper that is to fit into your machine. You can determine this by measuring the thinnest and thickest part of your Morse taper.

This drill chuck has a supplied MT 4 taper shank arbor with the 25.91 mm at the thinnest point and 31.54 mm at the thickest diameter. The taper shank arbor has an M 16 pull-in thread instead of a flat tang (ejector tang).

If this measurement does not fit, you can use the table to determine the correct Morse taper and call up the matching item in our shop.

Login