BAER HSSE Short Machine Tap 35° RSP - Rc (BSPT) 2'' x 11

In stock

BAER HSSE Short Machine Tap 35° RSP - Rc (BSPT) 2'' x 11

This BAER single flute tap is especially designed for use with the machine. Due to the 35° right-hand helix of the flutes, the chips are transported upwards out of the blind hole. However, spiral flutes cause an increased risk of breakage when used by hand. Therefore, care must be taken to ensure exact guidance. A machine guide is ideal for this. The tap cuts the finished internal thread in just one operation. The thread can be cut in a pre-drilled core hole and does not require any preparatory work by a taper tap (No. 1) or intermediate tap (No. 2).

Dimensions

| Diameter |

2" |

|---|---|

| Pitch |

11 |

| Dimension |

RC (BSPT) 2" x 11 |

| Square |

35 mm |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Short machine taps |

| Thread standard |

RC (BSPT): Tapered Whitworth pipe thread according to ISO 7/1 DIN EN 10226-2 |

| Tolerance |

medium |

| Direction |

Right |

| Standard |

JIS B-4445 |

| Tensile strength at room temperature |

up to 900 N/mm² | 27.1 HRC |

| Material |

HSSE bright |

Technical information – Screw taps

56 mm

Blind hole up to 2 x D

Form C 35° RSP

2-3 threads

Chips are removed upwards against the cutting direction

External cooling and lubrication

HSSE bright

up to 900 N/mm² | 27.1 HRC

medium

Applications

- General-purpose use

- Good machinable materials up to 900 N/mm²

- Unalloyed and low-alloy steels

- for blind holes

- for machine use

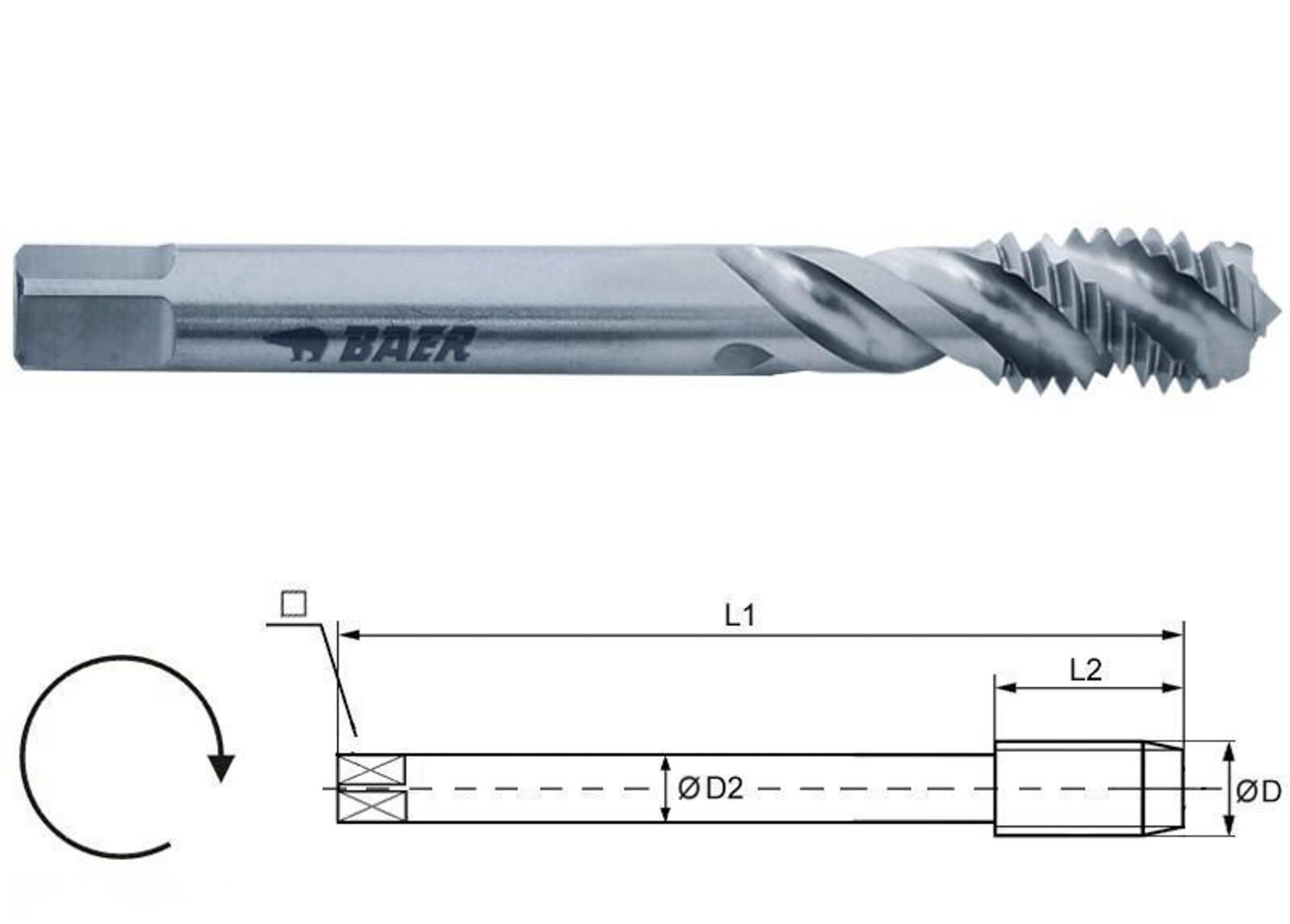

Technical drawing

| D1 |

RC (BSPT) 2'' x 11 |

|---|---|

| D2 |

46 mm |

| L1 |

120 mm |

| L2 |

50 mm |

| Diameter |

2" |

| Square |

35 mm |

Application – Sample materials for taps

| Unalloyed construction steels | |

|---|---|

| 1.0035 | S185 (St33) |

| 1.0036 | S235JRH |

| 1.0038 | RSt37-2 |

| 1.0039 | S235JRG1+CR |

| 1.0044 | St44-2 |

| 1.0060 | E335 (St60-2) |

| 1.0116 | St37-3 |

| 1.0570 | St 52-3 |

| Alloyed construction steels | |

|---|---|

| 1.5415 | 15Mo3 |

| 1.5423 | 16Mo5 |

| 1.5622 | 14Ni6 |

| 1.7335 | 13CrMo44 |

| 1.7337 | 16CrMo44 |

| 1.7715 | 14MoV63 |

| Free-cutting steels | |

|---|---|

| 1.0711 | 9S20 |

| 1.0715 | 9SMn28 |

| 1.0718 | 11SMnPb30 |

| 1.0721 | 10S20 |

| 1.0723 | 15S20 |

| 1.0726 | 35S20 |

| 1.0737 | 9SMnPb36 |

| 1.0758 | 60SPb20 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck45) |

| Cast steel | |

|---|---|

| 1.0420 | GS-38 |

| 1.5419 | GS-22 Mo 4 |

| 1.6750 | GS-20 NiCrMo3 7 |

| 1.7357 | GS-17 CrMo 5 5 |

| Malleable cast iron | |

|---|---|

| 0.8145 | EN-GJMB 450-6 |

| 0.8170 | EN-GJMB 700-2 |

| 0.8045 | EN-GJMW-450-7 |

| 0.8055 | EN-GJMW-550-4 |

| Pure copper low-alloyed | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

| Brass short-chipping | |

|---|---|

| 2.0401 | CuZn39Pb3 |

| Brass long-chipping | |

|---|---|

| 2.0321 | CuZn37 |

| 2.0335 | CuZn36 |

| 2.0360 | CuZn40 |

| Aluminum cast Si > 5-12 % | |

|---|---|

| 3.2161 | G-AlSi8Cu3 |

| 3.2163 | G-AlSi9Cu3 |

| 3.2381 | G-AlSi10Mg |

| 3.2583 | G-AlSi12(Cu) |

| Lamellar graphite cast iron | |

|---|---|

| 0.6010 | EN-GJL 100 (GG-10) |

| 0.6020 | EN-GJL 200 (GG -20) |

| 0.6025 | EN-GJL 250 (GG-25) |

| 0.6030 | EN-GJL 300 (GG -30) |

| Copper-tin alloy (bronze) short-chipping | |

|---|---|

| 2.1090.01 | G-CuSn7ZnPb |

| 2.1086.01 | G-CuSn10Zn |

| 2.1097 | G-CuSn5ZnPb |

| Pure copper, low-alloyed copper | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

Further information

Safety instructions

Login