BAER HSSE-TiN Machine Tap - 40° RSP - MF 10 x 1.25 - DIN 374

In stock

Express shipping available

BAER HSSE-TiN Machine Tap - 40° RSP - MF 10 x 1.25 - DIN 374

Our machine taps are powerful and reliable taps for efficient machining in one step with the machine. Machine taps are used especially in industrial manufacturing. They can be used in CNC machines, thread cutting machines, cordless drills and pneumatic tapping arms, among others. As they are characterised by high efficiency and low production costs, they are often used in series production. The thread is cut by machine in one operation. Thus, although the BAER machine tap can basically be compared with short machine taps, it is designed for use with the machine.

The machine tap can be used for blind holes, as the short chamfer and the spiral flutes ensure that the chip is discharged to the rear of the hole.

Every material shows individual chip behaviour. Therefore, screw taps must have the correct rake angle and - for even better results - a specially treated surface. This is the only way to achieve a good chip transport and to produce a thread that is true to gauge.

The high quality of the cobalt-alloyed HSSE steel we use ensures that our tools are extremely durable and robust. Due to special hardening processes and repeated tempering the hardness structure is very homogeneous, which forms the ideal basis for a genuine BAER screw taps. This increases the toughness and stability of the screw taps, allowing them to remain in use for longer.

The TiN coating is particularly suitable for soft to hard steels, cast iron and many non-ferrous metals. As a proven universal coating, TiN offers a wide range of applications. TiN-Tools can be recoated up to five times without prior decoating.

Dimensions

| Diameter |

10 |

|---|---|

| Nominal diameter in inches |

0,394 |

| Nominal diameter in mm |

10 |

| Pitch |

1,25 |

| Pitch in mm |

1,25 |

| Dimension |

MF 10 x 1,25 |

| Square |

5,5 mm |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Machine taps |

| Thread standard |

MF: Metric ISO fine thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

DIN 374 |

| Tensile strength at room temperature |

up to 1300 N/mm² | 41 HRC |

| Material |

HSSE TiN |

Technical information – Screw taps

8.8 mm

Blind hole up to 2.5 x D

Form C 40° RSP

2-3 threads

Chips are removed upwards against the cutting direction

External cooling and lubrication

HSSE TiN

up to 1300 N/mm² | 41 HRC

ISO2/6H

Applications

- Easy to difficult-to-machine materials up to a maximum of 1300 N/mm²

- Alloyed heat-treatable steels, nodular cast iron, malleable cast iron

- Cast aluminium and wrought alloys Si<5% (long-chipping)

- Copper alloys and brass (long-chipping)

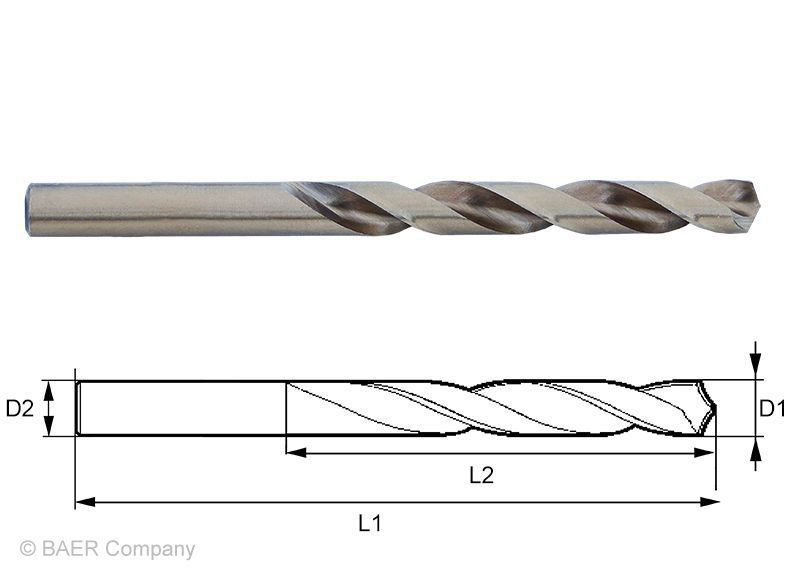

Technical drawing

| D1 |

MF 10 x 1.25 |

|---|---|

| D2 |

7 mm |

| L1 |

100 mm |

| L2 |

11,5 mm |

| Diameter |

10 |

| Square |

5,5 mm |

Application – Sample materials

| Alloyed steels, quenched and tempered steels | Cutting speed vc in m/min | |

|---|---|---|

| 1.7225 | 42CrMo4 | 5 - 20 |

| 1.2067 | 102Cr6 | 5 - 20 |

| 1.7228 | 50CrMo4 | 5 - 20 |

| 1.7108 | 60SiCr7 | 5 - 20 |

| Spheroidal graphite cast iron, malleable cast iron | Cutting speed vc in m/min | |

|---|---|---|

| EN-JS-1030 | EN-GJS-400-15 (GGG40) | 15 - 20 |

| EN-JS-1070 | EN-GJS-700-2 (GGG70) | 15 - 20 |

| 0.8055 | GTS55-05 | 15 - 20 |

| Stainless steels (ferritic, austenitic, martensitic) | Cutting speed vc in m/min | |

|---|---|---|

| 1.4105 | X6CrMoS17 | 8 - 10 |

| 1.4301 | X5CrNi18-10 (V2A) | 8 - 10 |

| 1.4571 | X6CrNiMoTi17-12-2 (V4A) | 5 - 7 |

Cutting speed vc [m/min] = (Outer diameter * π * speed) / 1000

Rotation speed n [1/min] = (Cutting speed in m/min * 1000) / (Outer diameter * π)

Feedrate programming [mm/min] = speed * pitch

Please note that the above cutting speeds are indicative and must be adjusted depending on lubrication and actuation.

Further information

- MF - ISO metric fine thread DIN 13

- Designations, geometries and definitions on taps

- Thread tolerances of the internal thread

- Internal thread and core hole dimensions

- Tap Chamfer forms

- Comparison inch-mm

- Surface treatments on tapping tools

- Cutting speeds and lubrication/cooling

- Information about tapping

- Material table

Safety instructions

Login