In stock

Express shipping available

BAER Set HSSG: Short Machine Taps | drill bits | tap holder: M 3 - 12

This tap set is a high quality and versatile set for all thread cutting needs. The metric taps from M 3 to M 12 enable the cutting of internal threads.

The set includes core drill bit and hand taps for through holes and blind holes made of ground HSS steel (High Speed Steel), which ensures long durability and high precision. Also included is a tap wrench to operate all screw tap in the set.

The thread cutting assortment is supplied in a sturdy plastic box. The compartments for the taps provide a secure hold and transport protection and at the same time all the tools are clearly within reach.

The tools themselves are characterised by the highest quality. They are optimally processed and guarantee long durability as well as high precision at thread cutting. In summary, this tap set offers an excellent solution for anyone who wants to cut threads. The combination of high-quality tools and a sturdy plastic box makes it an optimal choice for professionals and DIY enthusiasts alike. Invest in quality and experience the benefits of a professional tap set. A tap set that everyone needs in their workshop.

Dimensions

| Diameter |

3 - 12 |

|---|---|

| Dimension |

M 3 - 12 |

Characteristics

| Product group |

threading tool sets |

|---|---|

| Product type |

Threading tool sets |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Tensile strength at room temperature |

up to 900 N/mm² | 27.1 HRC |

| Material |

HSSG bright |

Technical information – Screw taps

Through hole and blind hole up to 2 x D

Form D straight fluted

3.5-5 threads

Chip removal (see illustration)

External cooling and lubrication

HSSG bright

up to 900 N/mm² | 27.1 HRC

ISO2/6H

Set content

| BAER HSSG machine taps | M 3 x 0,5 | M 4 x 0,7 | M 5 x 0,8 M 6 x 1,0 | M 8 x 1,25 | M 10 x 1,5 M 12 x 1,75 |

|---|---|

| BAER HSSG core drill bit | 2,5 mm | 3,3 mm | 4,2 mm | 5,0 mm 6,8 mm | 8,5 mm | 10,2 mm |

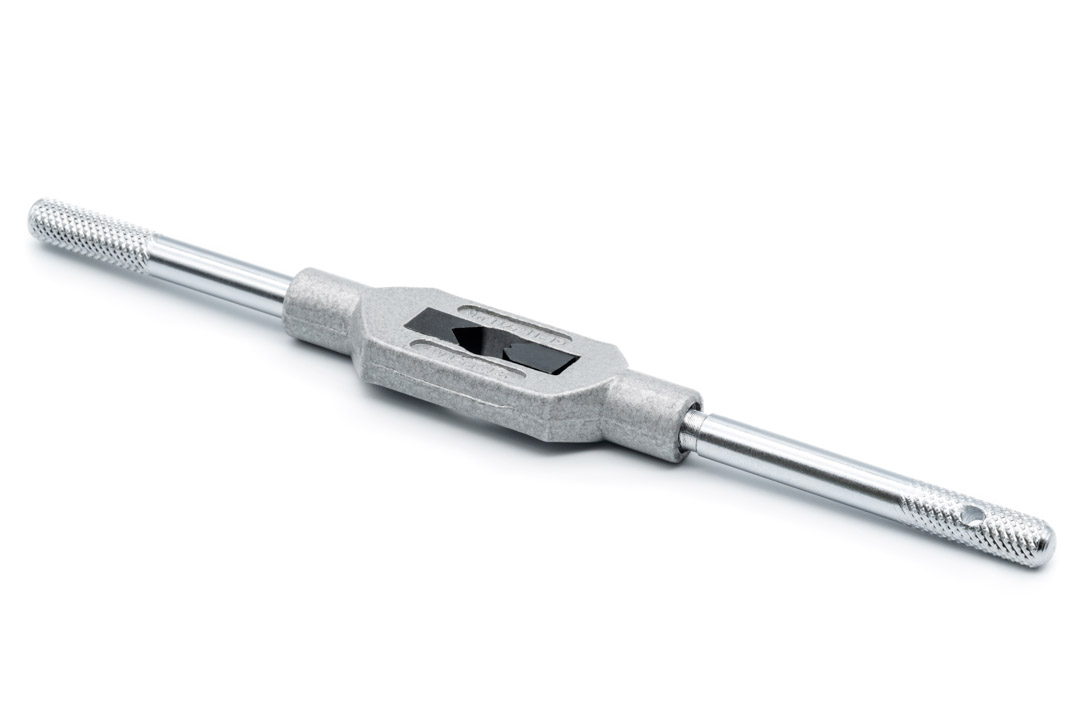

| BAER adjustable die-cast tap wrench | No. 1.1/2: M 1-12 | 1/16-1/2 | G 1/8 |

Applications

- General-purpose use

- Materials with good machinability up to 900 N/mm²

- Unalloyed and low-alloy steels

- for through hole and blind hole

- for manual use

Application – Sample materials for taps

| Unalloyed construction steels | |

|---|---|

| 1.0035 | S185 (St33) |

| 1.0036 | S235JRH |

| 1.0038 | RSt37-2 |

| 1.0039 | S235JRG1+CR |

| 1.0044 | St44-2 |

| 1.0060 | E335 (St60-2) |

| 1.0116 | St37-3 |

| 1.0570 | St 52-3 |

| Alloyed construction steels | |

|---|---|

| 1.5415 | 15Mo3 |

| 1.5423 | 16Mo5 |

| 1.5622 | 14Ni6 |

| 1.7335 | 13CrMo44 |

| 1.7337 | 16CrMo44 |

| 1.7715 | 14MoV63 |

| Free-cutting steels | |

|---|---|

| 1.0711 | 9S20 |

| 1.0715 | 9SMn28 |

| 1.0718 | 11SMnPb30 |

| 1.0721 | 10S20 |

| 1.0723 | 15S20 |

| 1.0726 | 35S20 |

| 1.0737 | 9SMnPb36 |

| 1.0758 | 60SPb20 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck45) |

| Cast steel | |

|---|---|

| 1.0420 | GS-38 |

| 1.5419 | GS-22 Mo 4 |

| 1.6750 | GS-20 NiCrMo3 7 |

| 1.7357 | GS-17 CrMo 5 5 |

| Malleable cast iron | |

|---|---|

| 0.8145 | EN-GJMB 450-6 |

| 0.8170 | EN-GJMB 700-2 |

| 0.8045 | EN-GJMW-450-7 |

| 0.8055 | EN-GJMW-550-4 |

| Pure copper low-alloyed | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

| Brass short-chipping | |

|---|---|

| 2.0401 | CuZn39Pb3 |

| Brass long-chipping | |

|---|---|

| 2.0321 | CuZn37 |

| 2.0335 | CuZn36 |

| 2.0360 | CuZn40 |

| Aluminum cast Si > 5-12 % | |

|---|---|

| 3.2161 | G-AlSi8Cu3 |

| 3.2163 | G-AlSi9Cu3 |

| 3.2381 | G-AlSi10Mg |

| 3.2583 | G-AlSi12(Cu) |

| Lamellar graphite cast iron | |

|---|---|

| 0.6010 | EN-GJL 100 (GG-10) |

| 0.6020 | EN-GJL 200 (GG -20) |

| 0.6025 | EN-GJL 250 (GG-25) |

| 0.6030 | EN-GJL 300 (GG -30) |

| Copper-tin alloy (bronze) short-chipping | |

|---|---|

| 2.1090.01 | G-CuSn7ZnPb |

| 2.1086.01 | G-CuSn10Zn |

| 2.1097 | G-CuSn5ZnPb |

| Pure copper, low-alloyed copper | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

Further information

Safety instructions

BAER HSSG short machine tap

for through-hole and blind hole | M 3 - M 12 threads

Cutting a finished thread with just one tool in one operation, even by hand - is that possible? Yes, the short machine tap makes efficient production of internal threads possible. Whether by hand or semi-professionally by machine, this internal tap with full thread profile cuts precisely and saves time. At the same time, it cuts precisely and straight into the core hole - an absolute must when drilling threads. BAER short machine taps are suitable for general use in easily machinable materials up to 800 N/mm². These include unalloyed and low-alloy steels, free-cutting steels and cast steel. They cut a through-hole and blind hole up to 2 x D and are suitable for hand and machine use.

The advantages at a glance:

- Thread cutting with one tool

- precise and time-saving

- for hand and machine use

- Use in materials with good machinability up to 800 N/mm²

- Through-hole and blind hole up to 2 x D

- Hand and machine use

Technical information:

- Form D: 3.5 - 5 threads chamfer

- Thread tolerance: ISO2/6H

BAER HSSG twist drill bit

core drill bit for M 3 - M 12 threads

Our twist drill bit work with a very high accuracy and very low tolerances, thus high-precision work with a high tool life time is possible. The result: an exact hole. The spiral as well as the cutting edges have an ideal self-centring behaviour due to their split point and have a good chip evacuation. HSSG drills can be used in CNC machines, drill presses, drill presses, cordless screwdrivers, percussion drills and hammer drills, among others. They are perfect for drilling into materials such as steel, cast steel, cast iron, sintered iron, graphite, brass, aluminium and bronze and retain their hardness up to approx. 600°C, right, with cylindrical shank according to DIN 338. Furthermore, the twist drill bit are also suitable for the universal use, of course you can also drill into wood or aluminium. As they are characterised by high efficiency and low production costs, they are often used in series production. Twist drill bit with cylindrical shank are suitable for use in all drill chucks and can be clamped in the same way as in quick-change drill chuck as well as keyed drill chuck.

The advantages at a glance:

- high accuracy and very low tolerances → precise drill hole

- Cross grinding → ideal self-centring behaviour and good chip evacuation

- Cylindrical shank → suitable for all drill chucks

- Can be used as a universal tap

This means that BAER hand taps and dies made of high-speed steel HSS can also cope with many material requirements. Accurate work and long-term cost savings are added to this.

BAER adjustable tap wrench made of zinc die cast

DIN 1814, zinc die-cast body, hardened jaws

The adjustable tap wrench is a holding tool for cutting internal thread by hand. The quality of a tap wrench lies in the material as well as in the clamping jaws, the holding handles and the geometry. The long levers on the right and left help to cut plumb into the hole and easily apply the required torque. The compact and robust design in the zinc die casting ensures an excellent price-performance ratio. Another advantage is the easy handling and the short changing times.

This adjustable tap wrench made of zinc die cast is suitable for the following use:

- Square: 2.1 - 8.0 mm

- for screw tap: M 1-12 | 1/16-1/2 | G 1/8

Quality

for long service life

The high-alloy tool steel HSS can work with up to four times higher cutting speeds than ordinary tool steel.

This set is characterised by:

- Temperature resistance / heat hardness

- Wear resistance

- Cutting edge stability

- high smooth running

- good chip evacuation

This means that BAER hand taps and dies made of high-speed steel HSS can cope with many material requirements. Accurate work and long-term cost savings are added to this.

Login