BaerCoil Thread Repair Kit M 24 x 3.0 screw grip (screw locking)

In stock

BaerCoil Thread Repair Kit M 24 x 3.0 screw grip (screw locking)

With this BaerCoil® thread repair set it is possible to repair through hole and blind-hole threads in M 24 x 3.0 while maintaining a screw-locking thread.

BaerCoil® thread inserts are the best solution for all your thread repair needs! With them you are able to make durable and strong connections. With the inserts you avoid waste in your components and can recycle them. The inserts are precise and wear resistant - your screw will stay firmly in place without the thread insert slipping out.

The BaerCoil® thread insert is the perfect solution for damaged threads without changing the nominal diameter. For the thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) is cut for the wire thread insert. This thread is often also called STI thread (STI=Screw Thread Insert). Then the BaerCoil® thread insert is screwed into the old thread and thus the workpieces are screwed back together. With BaerCoil® thread inserts, the thread produced is significantly more stable than the original thread.

Our thread inserts ensure that both static and dynamic work loads are distributed evenly over the individual thread turns. In addition, the flexibility of the thread inserts compensates for possible pitch and angular errors so that optimum force transmission from the bolt to the nut thread is achieved. Especially in lightweight constructions, BaerCoil® thread inserts help to save carrier material and to use smaller or shorter screw connections. They are already an important component in aviation and vehicle construction. They significantly save material and contribute to the conservation of resources.

For repair directly on the thread, this thread repair kit contains various auxiliary tools, such as the hand tap with oversize for insert threads, insertion tool and wire thread inserts made of stainless steel.

This set does not include twist drill bit and tang breaker. To drill the core hole, a 24.50 mm twist drill bit is still needed here. The tenon can be broken with the installation tool. To do this, pull back the installation tool after installation and turn it 90° so that it rests on the tenon. Then hit the tool briefly at the back.

With the self-clamping "screw grip

"thread inserts, your construction will remain stable - regardless of shocks, constant vibrations or movements. The screw-locking BaerCoil® thread inserts complement the properties of the "free-flowing" connection and have a clamping effect on the flanks of the screwed-in screw due to their polygonally shaped windings. Please use only screws of a higher strength class for this purpose, as an elastically resilient frictional connection is created.

Theclamping torques are comparable to the specifications in DIN 267 Part 15 and ISO 2320. Please note that special insertion tools with reduced diameters are required for screw grip

inserts.BaerCoil® screw-locking thread inserts | Type "screw grip

"- All advantages at a glance

With the self-clamping "screw grip" thread inserts, your construction remains stable - regardless of whether it is subject to shocks, constant vibrations or movements. The screw-locking BaerCoil® thread inserts complement the properties of the "free running" connection and have a clamping effect on the flanks of the screwed-in screw due to their polygonally shaped windings. Please use only screws of a higher strength class for this purpose, as an elastically resilient frictional connection is created.

Theclamping torques are comparable with the specifications in DIN 267 Part 15 and ISO 2320. Please note that special insertion tools with reduced diameter are required for screw grip inserts.

24.5 mm twist drill bit required. The spigot can be broken with the installation tool. To do this, pull back the installation tool after installation and turn it 90° so that it rests on the spigot. Then hit the tool briefly at the back.BaerCoil® thread inserts can be shortened with a side cutter or similar if necessary, according to the required length. Note that the thread inserts with screw locking have a polygonal winding in the middle of the insert. This must not be removed when shortening in order to maintain the screw locking effect.

Dimensions

| Diameter |

24 |

|---|---|

| Pitch |

3,0 |

| Dimension |

M 24 x 3,0 |

| Length |

1,5 D |

| T (Length when installed) |

36 mm |

| Thread length calculation |

1.5 D means 1.5 times the diameter: 1.5 times 24 mm=36 mm

The nominal diameter for M 24 is 24 mm |

Characteristics

| Product group |

Wire thread inserts - Repair kits |

|---|---|

| Product type |

BaerCoil thread repair kits |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

screw grip (screw locking) |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

All normal applications for thread repair and for thread reinforcement of blind hole threads. Due to the screw-locking properties of thread inserts, the repair kit is particularly suitable for applications in which the screw must not come loose in case of shocks and vibrations.

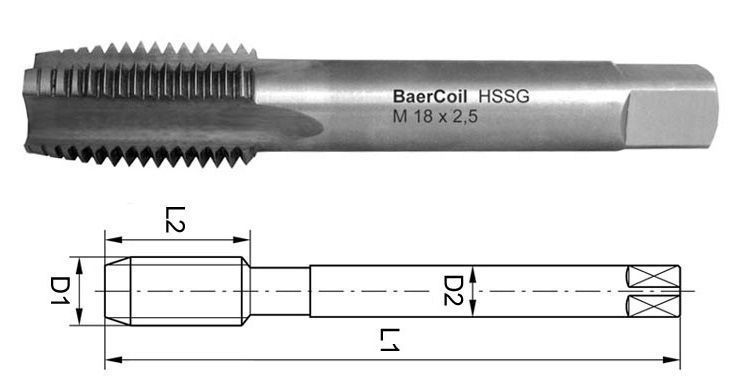

Technical drawing

| Diameter |

24 |

|---|---|

| Length |

1,5 D |

| T (Length when installed) |

36 mm |

| F (Min. - Max. outside diameter of thread insert) |

27,43 mm - 29,00 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

46,50 mm |

| D (minimum depth of the core hole, without tip) |

49,50 mm |

Content

- 1 x B3044-1: BaerCoil HSSG single-cut tap M 24 x 3.0 EG

- 1 x EBW24: BaerCoil Installation tool M 24 x 3.0

- 5 x BS7245-15: BaerCoil thread inserts M 24 x 3.0 - length: 1.5 D - type: "screw grip" - material: A2 (1.4301) - tolerance ISO 2 (6H)

Video instructions

Login