BaerCoil Wire Thread Inserts M 3 x 0.5 - 1.5 D (4.5 mm) - free running - Bronze - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts M 3 x 0.5 - 1.5 D (4.5 mm) - free running - Bronze - 100 pcs.

BaerCoil® thread inserts are the perfect solution for your thread repair needs! These inserts provide a durable and powerful thread connection and scrap recovery.

For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) is cut for the wire- thread insert. Often this thread is also called STI thread (STI=Screw Thread Insert).

BaerCoil® thread inserts are essential for optimal power transmission in lightweight constructions. They ensure that both static and dynamic work loads are distributed in a balanced manner to the individual thread turns. Also, the flexibility of the thread inserts compensates for any pitch and angle errors. BaerCoil® thread inserts not only save time and money, but are also much lighter and more compact than conventional screw connections.

BaerCoil® thread inserts can be shortened, according to the required length, with a side cutter or similar.

Dimensions

| Diameter |

3 |

|---|---|

| Pitch |

0,5 |

| Dimension |

M 3 x 0,5 |

| Length |

1,5 D |

| T (Length when installed) |

4,5 mm |

| Thread length calculation |

1.5 D means 1.5 times the diameter: 1.5 times 3 mm=4.5 mm The nominal diameter for M 3 is 3 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

> 900 N/mm² |

| Material |

from Bronze (CuSn6, CW452K, material no.: 2.1020) |

| Temperature resistance |

250°C long-term 300°C short-term |

Applications

- Applications in seawater

- Best electrical conductivity

Attributes

- Movement thread

- Cr-Ni screws

- Cu workpieces

- Non-magnetic

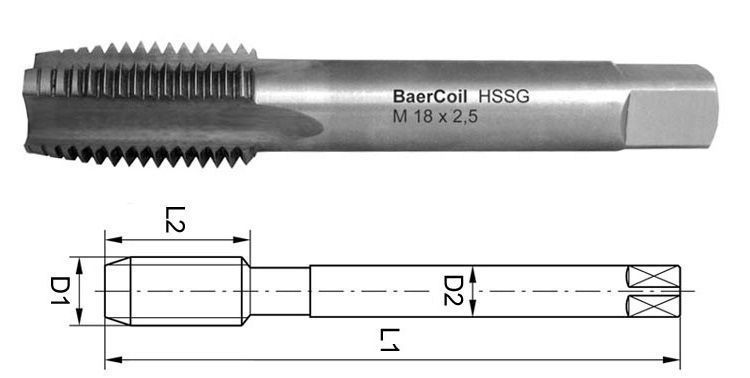

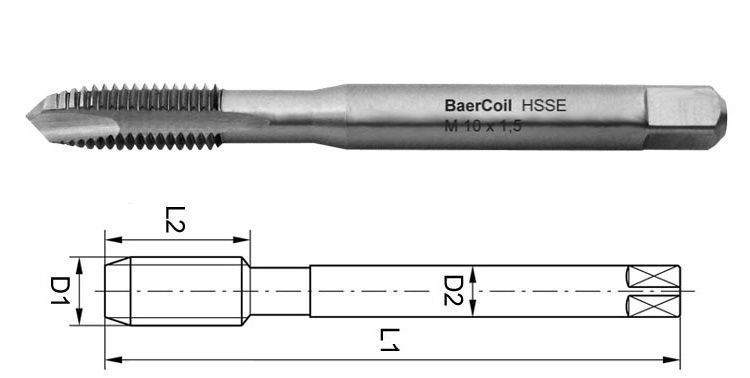

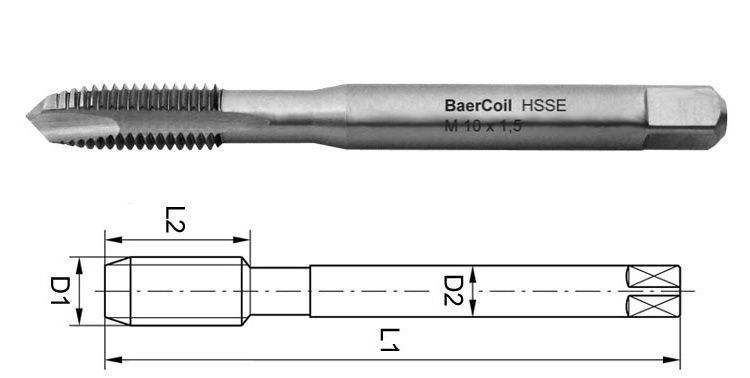

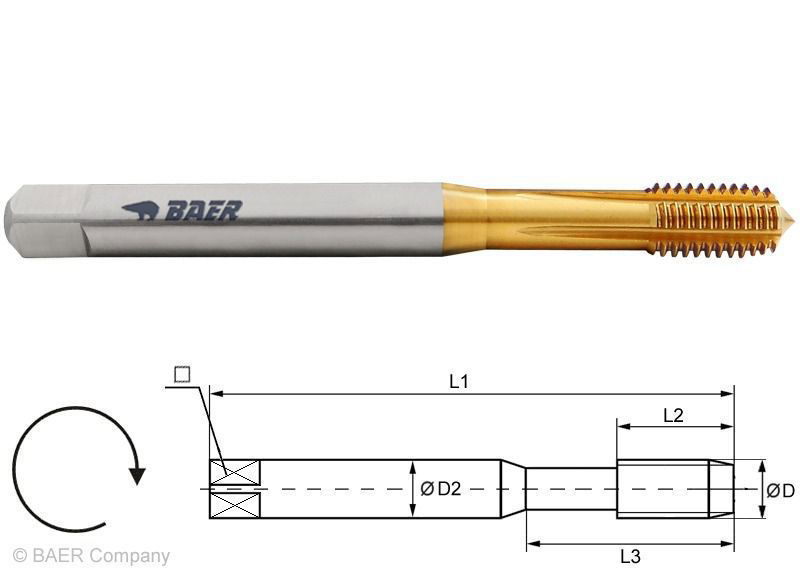

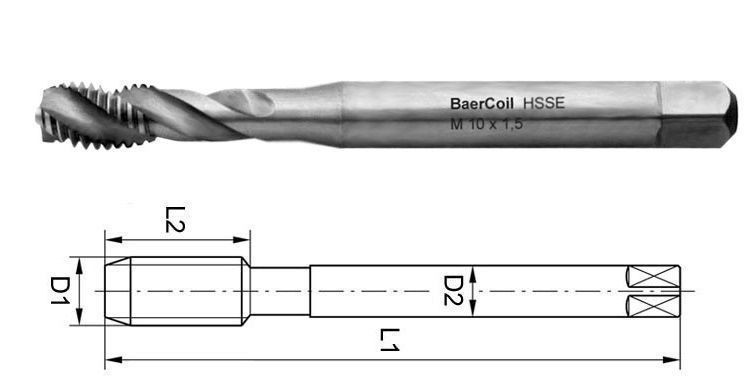

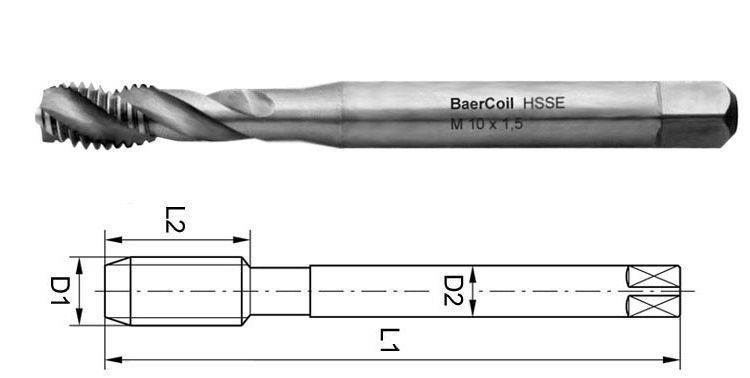

Technical drawing

| Diameter |

3 |

|---|---|

| Length |

1,5 D |

| T (Length when installed) |

4,5 mm |

| F (Min. - Max. outside diameter of thread insert) |

3,60 mm - 4,35 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

6,25 mm |

| D (minimum depth of the core hole, without tip) |

6,75 mm |

Video instructions

Further information

Product data sheet

Safety instructions

Login