BaerCoil Wire Thread Inserts M 6 x 1.0 - 2.0 D (12 mm) - free running - Inconel X750 - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts M 6 x 1.0 - 2.0 D (12 mm) - free running - Inconel X750 - 100 pcs.

BaerCoil® wire thread inserts are the perfect solution for a durable, powerful threaded connection and With the BaerCoil® wire thread inserts you create perfect, durable and powerful threaded connections. At the same time, the use of wire thread inserts allows for scrap recovery and load-bearing connections in materials with low shear strength. Therefore, wire thread inserts is often used in automotive, electrical engineering, medical technology, lightweight construction and aerospace.

The BaerCoil® thread insert is the perfect solution for damaged threads. For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) is cut for the wire- thread insert.

BaerCoil® thread inserts are perfect for applications where a balanced distribution of forces is required. They can withstand both static and dynamic loads and help save support material.

BaerCoil® thread inserts can be shortened, according to the required length, with a side cutter or similar.

Dimensions

| Diameter |

6 |

|---|---|

| Pitch |

1,0 |

| Dimension |

M 6 x 1,0 |

| Length |

2,0 D |

| T (Length when installed) |

12 mm |

| Thread length calculation |

2.0 D means 2 times the diameter: 2 times 6 mm=12 mm The nominal diameter for M 6 is 6 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1150 N/mm² |

| Material |

Inconel X750 (NiCr15Fe7TiAl, material no.: 2.4669) |

| Temperature resistance |

550°C long-term 750°C short-term |

Applications

- Aerospace

- Turbocharger

- Aircraft engines

- Turbines

- Thermal power plants

Attributes

- high thermal resistance

- high corrosion protection

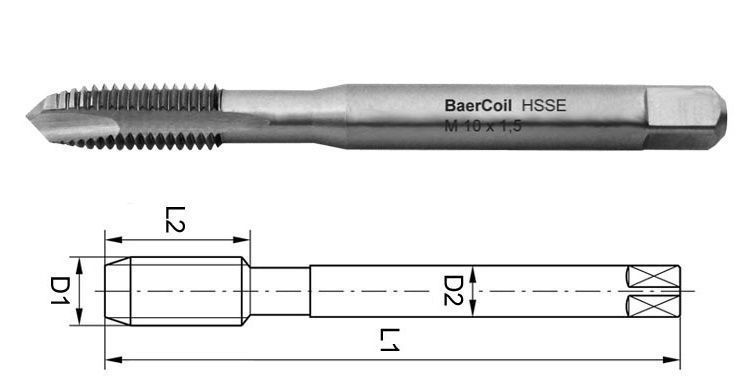

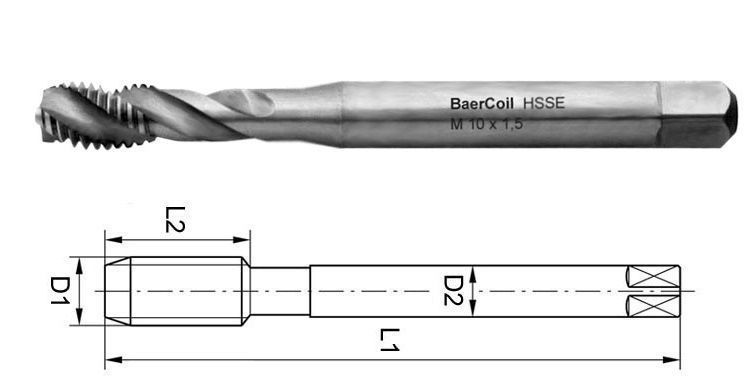

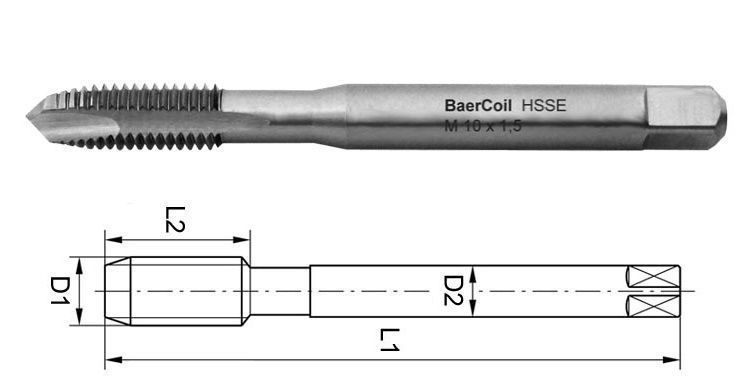

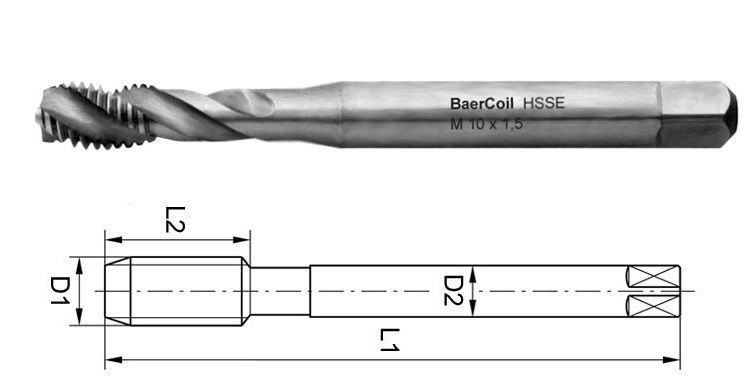

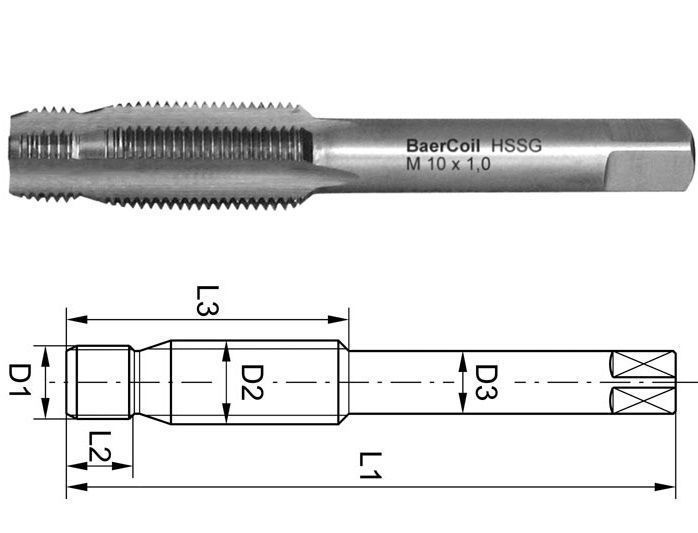

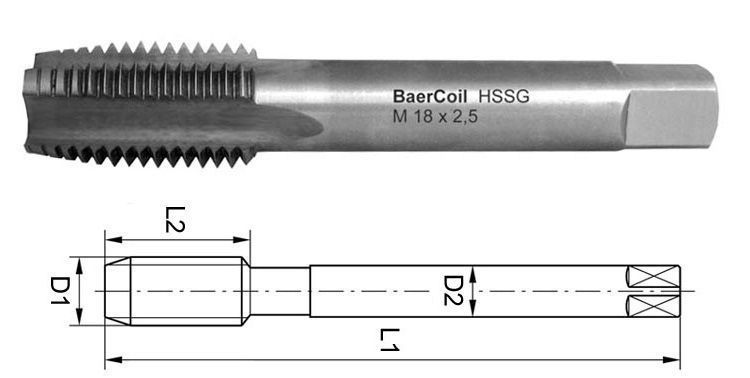

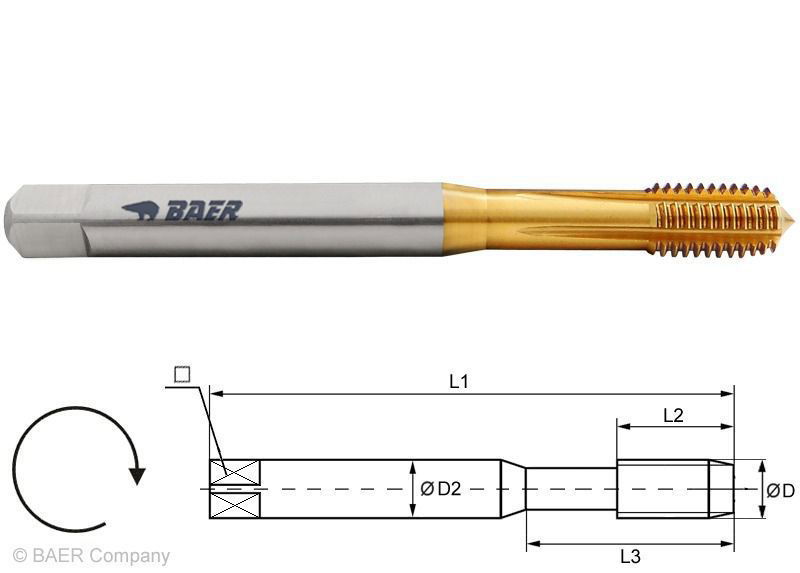

Technical drawing

| Diameter |

6 |

|---|---|

| Length |

2,0 D |

| T (Length when installed) |

12 mm |

| F (Min. - Max. outside diameter of thread insert) |

7,17 mm - 7,95 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

15,50 mm |

| D (minimum depth of the core hole, without tip) |

16,50 mm |

Video instructions

Further information

Product data sheet

Safety instructions

Login