BaerCoil Wire Thread Inserts UNF No. 5 x 44 - 1.0 D (3.18 mm) -100 pcs.

In stock

BaerCoil Wire Thread Inserts UNF No. 5 x 44 - 1.0 D (3.18 mm) -100 pcs.

BaerCoil® thread inserts provide a long-lasting and powerful thread connection and scrap recovery. The inserts also create load-bearing connections in materials with low shear strength. thread inserts are precise and wear-resistant, holding your screw firmly in place without changing the thread insert. Ideal for repairing stripped or worn threads. wire thread inserts are commonly used in automotive, electrical, medical, lightweight construction, and aerospace applications.

The BaerCoil® thread insert is the perfect solution for damaged threads. With the use of BaerCoil® thread inserts, the thread produced is significantly more stable than the original thread.

BaerCoil® thread inserts are an indispensable component in aviation and vehicle construction. They ensure that both static and dynamic work loads are distributed in a balanced manner over the individual thread turns. Also, the flexibility of the thread inserts compensates for any pitch and angular errors, so that optimum power transmission from the bolt to the nut thread is achieved. Especially in lightweight constructions, BaerCoil® thread inserts help to reduce the carrier material and to use smaller or shorter screw connections. Thanks to their versatility and reliability, BaerCoil® thread inserts are now an indispensable component in many industries.

BaerCoil thread inserts can be shortened to the required length with a side cutter or similar.

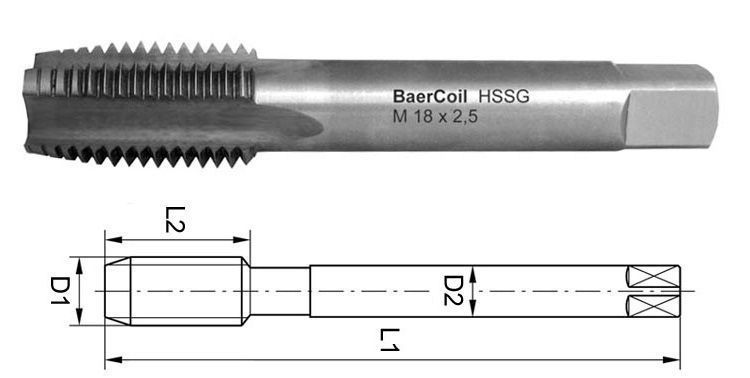

Dimensions

| Diameter |

No. 5 |

|---|---|

| Pitch |

44 |

| Dimension |

UNF No. 5 x 44 |

| Length |

1,0 D |

| T (Length when installed) |

3,18 mm |

| Thread length calculation |

1.0 D means 1 times the diameter: 1 times 3.18 mm=3.18 mm The nominal diameter for UNF No. 5 is approx. 3.18 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

UNF: American Fine Unified National thread according to ANSI B1.1 |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and thread reinforcement

Technical drawing

| Diameter |

No. 5 |

|---|---|

| Length |

1,0 D |

| T (Length when installed) |

3,18 mm |

| F (Min. - Max. outside diameter of thread insert) |

0,152 '' - 0,168 '' |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

0,205 '' |

| D (minimum depth of the core hole, without tip) |

0,227 '' |

Video instructions

Further information

Product data sheet

Safety instructions

Login