HSSE Extreme Drill Bit 8.25 mm - 5 pcs.

In stock

Express shipping available

HSSE Extreme Drill Bit 8.25 mm - 5 pcs.

At BAER you can get twist drill bit in tested BAER-industrial quality. Especially when it comes to tools, it is always worth spending a few euros more. Our twist drill bit are ideal for drilling a precise hole. The twist drill bit are particularly stable and made of cobalt-alloyed high-speed steel and retain their hardness up to approx. 600°C. Profile-ground cobalt drills with an extremely high runout accuracy are suitable for drilling iron + steel and bronzes up to 1300 N/mm² as well as high-strength CrNi-based alloys and rust-, acid- and heat-resistant steels, right with cylindrical shank according to DIN 338. twist drill bit with cylindrical shank are suitable for use in all drill chucks and have ideal self-centring properties due to their cross-grinding (from ⌀ 3.0 mm).

CAUTION:

Do not drill into pre-drilled holes! (Drills can break due to the split point. The cutting edges wear more quickly and unevenly). Always drill only into the full material at the appropriate speed.

Dimensions

| Diameter |

8,25 mm |

|---|---|

| Dimension |

8,25 mm |

| Length |

117 mm |

| Machine mount |

cylindrical shank |

Characteristics

| Product group |

Twist drill bits |

|---|---|

| Product type |

Twist drill bits |

| Direction |

Right |

| Standard |

DIN 338 |

| Type |

N (135° tip angle with split point) |

| Material |

5% cobalt alloyed HSSE high speed steel |

Applications

Suitable for iron, steels, bronze up to 1300 N/mm², high-strength CrNi-based alloys, rust-resistant steels, acid-resistant steels, heat-resistant steels, wood, aluminium

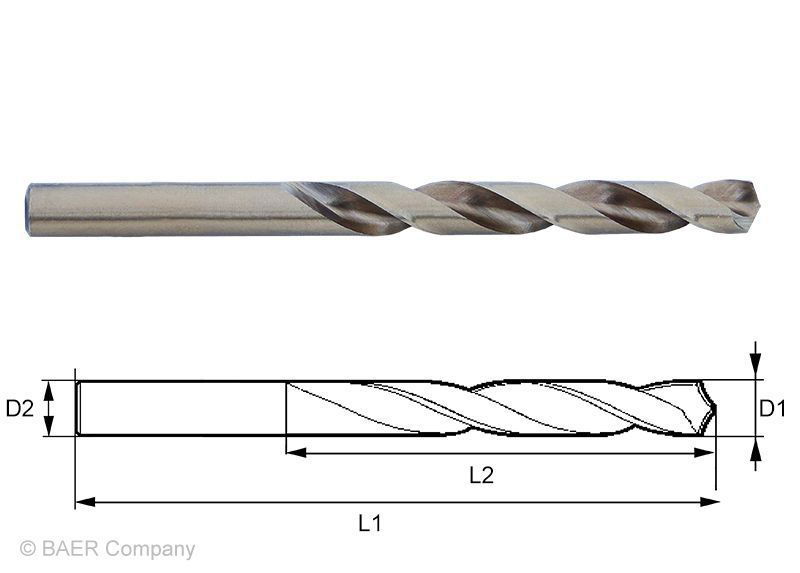

Technical drawing

| D1 |

8,25 mm |

|---|---|

| L1 |

117 mm |

| L2 |

75 mm |

| Diameter |

8,25 mm |

| Length |

117 mm |

Safety instructions

Extreme drill bit DIN 338, right-hand cutting with cylindrical shank

ground from the solid, HSSE/co-steel, with X-TRA split point

Our twist drill bit are mainly used in industrial production. Among other things, they can be used in CNC machines, pillar drills, drill presses, cordless screwdrivers, impact drills and hammer drills. With their cylindrical shank, they can be clamped in both quick-change drill chuck and keyed drill chuck. The drills have a split point and the point angle is 135°.

As they are characterised by high efficiency and low production costs, they are often used in series production

Universal drills for every application

Every material has its own individual machining behaviour. That is why twist drill bit must have the right geometries and be made of high-quality materials. Twist drill bit consists of the drill shank, the chip-removing flutes and the drill point. Decisive for the application range of the drill is not only the material, but also the cutting edge geometry, the rake angle and the helix angle, the so-called twist. This is the only way to ensure a good chip transport and a dimensionally accurate hole. The extreme twist drill bit is ideal for drilling iron, steel and bronze up to 1300 N/mm² as well as high-strength CrNi-based alloys, rust-, acid- and heat-resistant steels. Of course, you can also drill in wood or aluminium.

Quality for a long service life

The high-alloy tool steel allows up to four times higher cutting speeds than conventional tool steel. Due to the cobalt alloy (5%), the material is more heat-resistant and has a higher hardness than HSSG drills. It retains its hardness up to approx. 600-650 °C.

Our twist drill bit are characterised by:

- Temperature resistance / hardness

- close tolerances

- Self-centering

- Wear resistance

- Cutting edge stability

- high smooth running

- good chip removal

This means that BAER twist drill bit can cope with many material requirements. Precise work and long-term cost savings are added to this.

Login