-

Taps & Dies

-

Thread standards

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- UN - amer. with special pitch

- UNS - amer. with special pitch

- BSW - british coarse thread

- BSF - British fine thread

- Tr - trapezoidal thread

- Rd - knuckle thread

- NPT - amer. taper pipe thread

- NPTF - amer. taper pipe thread

- NPS - amer. cyl. pipe thread

- Rc (BSPT) - taper pipe thread

- Rp (BSPP) - cyl. pipe thread

- Vg - valve thread

- BA - brit. assn. Thread

- BSB - BSC - brit. std. thread

- W - taper gas cylinder valves

- Electrical and cable thread

- Bicycle and pedal thread

- Photo and C-Mount Thread

- Mini and nano threads (< 2mm)

- PG - steel conduit thread

- S - buttress thread

- RMS - microscope thread

- MJ, UNJC, UNJF - Aviation

- STI thread (thread inserts)

- Special thread

- Operating tools

- Lubricant

- Thread restoration tools

- Countersink

- Step drills

- Thread gauges

-

Thread standards

- Twist drill bits

- Drill chucks

- BaerCoil/BaerFix

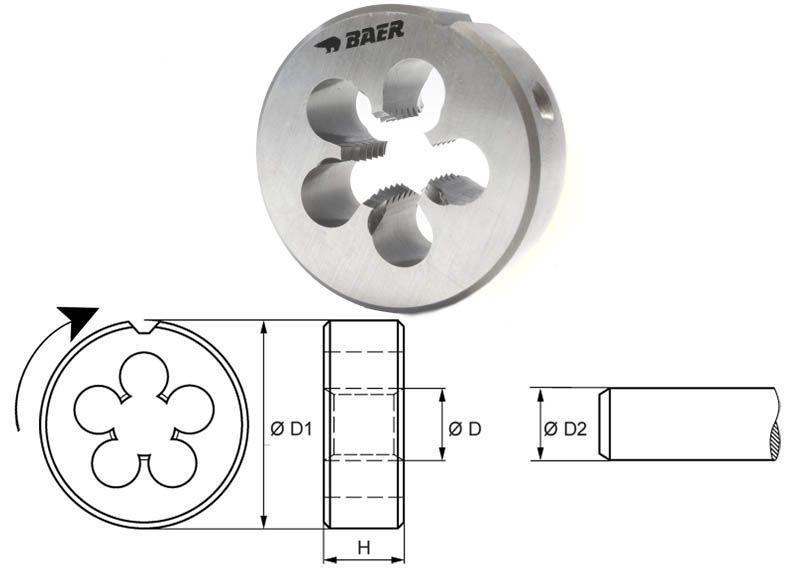

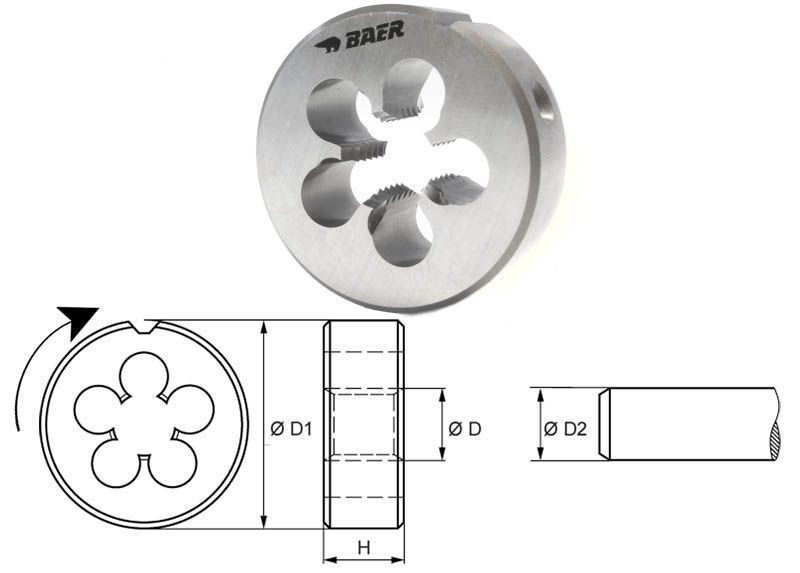

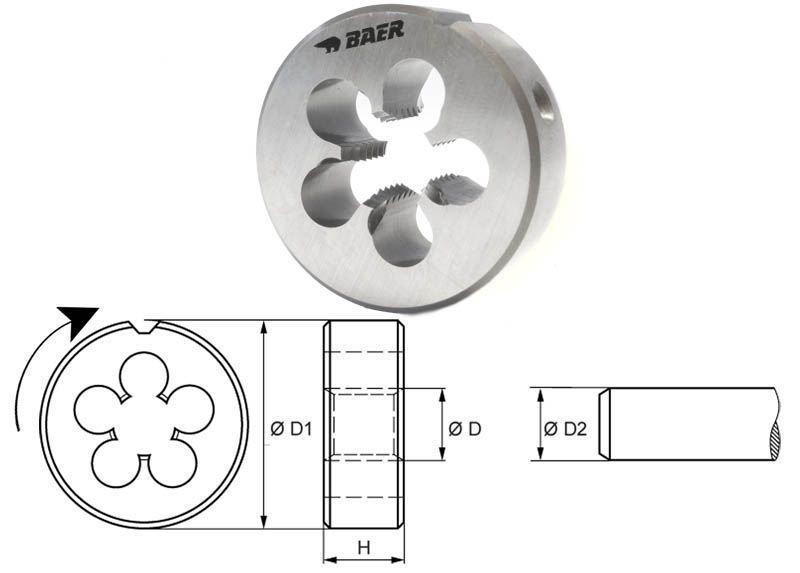

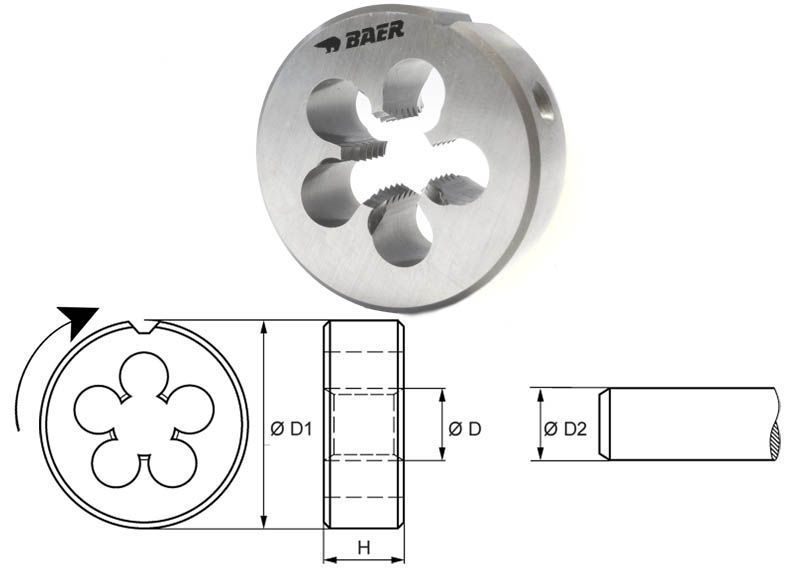

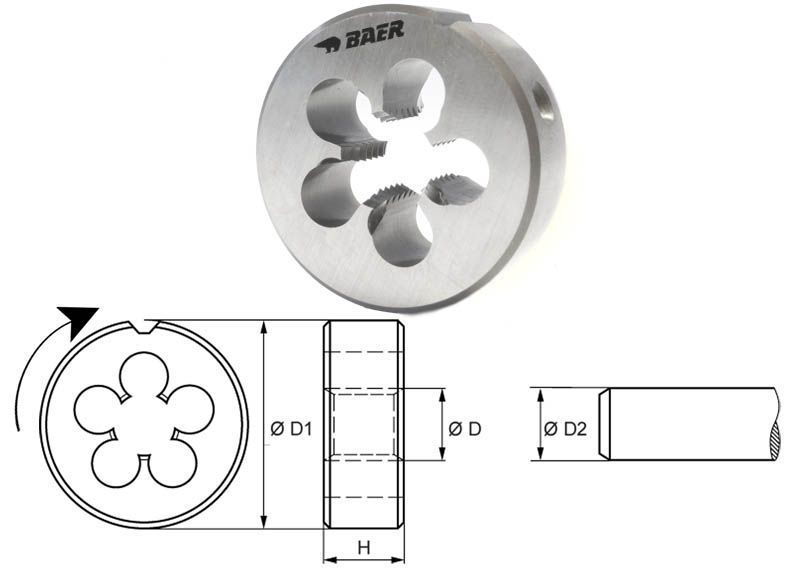

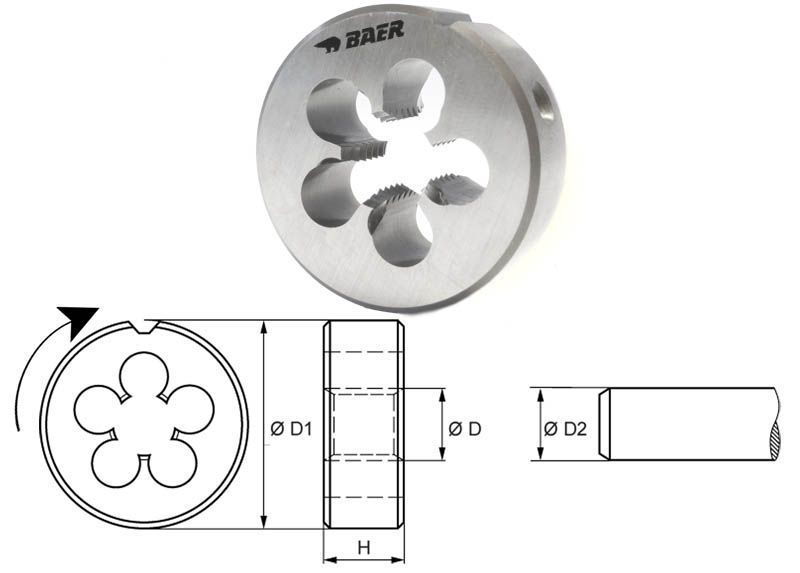

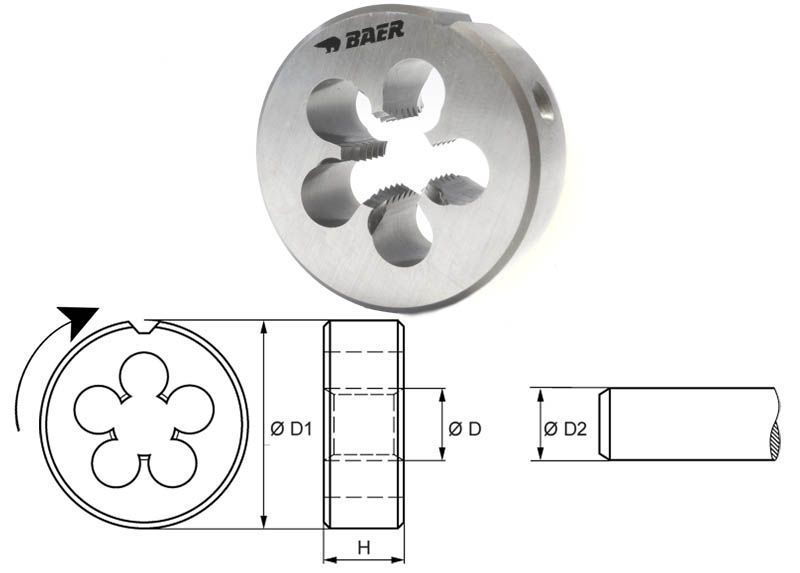

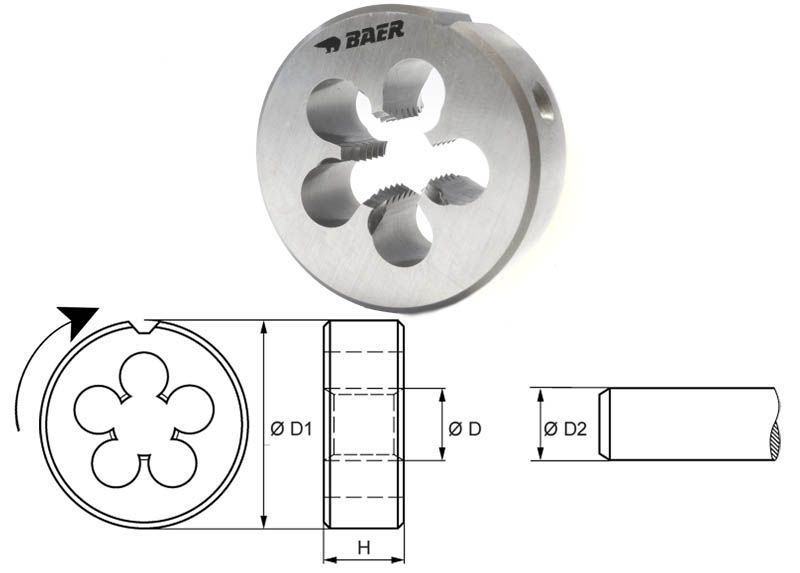

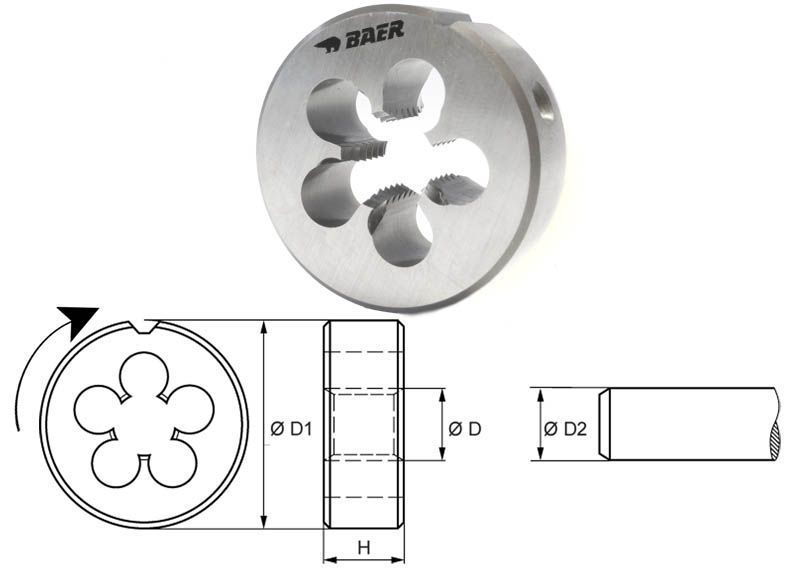

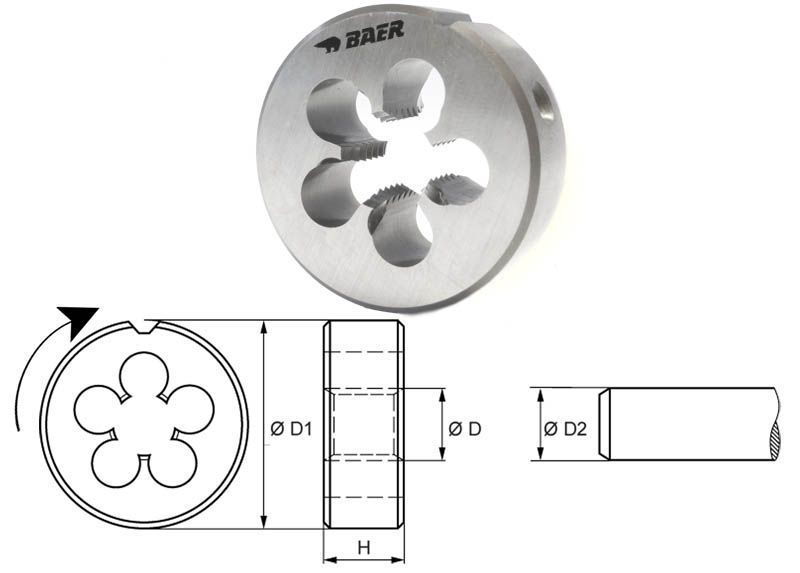

Metric round thread cutting dies for stainless steels

Toolfinder

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

There are also many specialists at thread cutting dies, such as thread cutting dies for stainless steel. For optimum work results, you should always pay attention to which category your area of application falls into. Although the majority of thread cutting cases can be processed with a normal thread cutting die, not all of them can. If such a special case slips through, it can quickly cause annoying damage to the component or tool. This is especially true if you are working with materials with special properties. This is why you should always use a thread cutting die for stainless steel if you want to machine bolts made from this material. With such a thread cutting die you can then be sure that the thread has the desired properties and is cut precisely.

Of course, it is also important to order the thread cutting dies for stainless steel from a trustworthy manufacturer. You've come to the right place with BAER. Our thread cutting dies for stainless steel are not only perfectly tailored to your demanding area of application, but are also manufactured with particular care. With our thread cutting dies you work quickly and cleanly and can also look forward to a long service life.

To process stainless steel, you need a special thread cutting die for stainless steel

Thread cutting die for stainless steel is an indispensable tool when it comes to cutting external threads in stainless steel bolts. But why is that actually the case? What are the properties of this special material that make it necessary to use a special cutting die for stainless steel?

Stainless steel is often equated with rustproof steel, but this is only half the truth. In fact, not all stainless steel is stainless steel and vice versa. However, when it comes to cutting die for stainless steel, in the vast majority of cases we are talking about stainless steel. The best-known representatives of this type are INOX, V2A and V4A. Before you use the cutting die, it is best to check once again whether your bolt is actually one of these variants.

Stainless steel is characterised by a number of special properties. These can vary depending on the alloy. What all stainless steel grades have in common, however, is their high resistance - to rust, corrosion or even special temperature conditions. However, this also means that stainless steel is difficult to machine. We don't like to hear that thread cutting naturally don't like to hear that. This is precisely why there is cutting die for stainless steel. Because such a cutting die is designed precisely for the properties that make stainless steel such a special material and can handle the challenge with ease.

A cutting die for stainless steel is optimised for the material

The most important criterion is the starting material of the tool. After all, the cutting die for stainless steel must be able to cope with the special properties of stainless steel and therefore be made of a material that can withstand the corresponding loads. In addition, high temperatures are often generated during machining, which the cutting die for stainless steel must also be able to withstand without becoming deformed or damaged.

To equip the cutting die for stainless steel with the required properties, HSSE is the ideal starting material. HSSE is a special variant of the already very high-quality high-speed steel. The cutting die are made from a high-speed steel that contains around 5% cobalt. Cobalt as an alloying element brings two valuable improvements. On the one hand, the cobalt content increases the hardness, and on the other hand, the resistance to heat hardening. It is the perfect alloy that optimally prepares the cutting die for its later use.

In addition to the material, excellent processing is also particularly important for stainless steel cutting die. Sharp cutting edges and a perfectly smooth surface ensure that the cutting die glides smoothly through the stubborn material and guarantee good chip removal.

How to work with a cutting die for stainless steel

Once you have found a suitable cutting die, cutting a thread in the stainless steel bolt works just like you are used to from other jobs. Nevertheless, you should take particular care when working. Pay attention to the correct bolt preparation diameter. If it is too large, the cutting die for stainless steel will have to do too much cutting work and will eventually stop moving or even cause damage. When using a cutting tool for stainless steel, you should also make sure you use a sufficient amount of lubricant and top up if necessary. Working with the cutting die can quickly lead to high temperatures, which should be absorbed by a suitable cooling lubricant.

Otherwise, you can cut the external thread with a cutting die for stainless steel even in this difficult material both by hand and with the machine. All you need is the right die holder or a suitable holder. When using a die holder, you should also use a die guide to make your work easier.

You can find these cutting die for stainless steel in the BAER online shop

With the cutting die for stainless steel from the BAER online shop, you can conquer even the most stubborn types of steel. Our cutting die are all made from high-quality high-speed steel with cobalt alloy (HSSE) and are also nitrided. The nitriding gives the cutting die a higher surface hardness and also improves wear resistance and sliding properties. You can find metric cutting die for stainless steel in the BAER range in all standard sizes from M 1.4 to M 30.

Do you have any questions about our cutting die for stainless steel or would you like to find out more about the benefits before purchasing? You can contact our competent customer service team of expert screw tap manufacturers at any time using the contact form.