-

Taps & Dies

-

Thread standards

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- UN - amer. with special pitch

- UNS - amer. with special pitch

- BSW - british coarse thread

- BSF - British fine thread

- Tr - trapezoidal thread

- Rd - knuckle thread

- NPT - amer. taper pipe thread

- NPTF - amer. taper pipe thread

- NPS - amer. cyl. pipe thread

- Rc (BSPT) - taper pipe thread

- Rp (BSPP) - cyl. pipe thread

- Vg - valve thread

- BA - brit. assn. Thread

- BSB - BSC - brit. std. thread

- W - taper gas cylinder valves

- Electrical and cable thread

- Bicycle and pedal thread

- Photo and C-Mount Thread

- Mini and nano threads (< 2mm)

- PG - steel conduit thread

- S - buttress thread

- RMS - microscope thread

- MJ, UNJC, UNJF - Aviation

- STI thread (thread inserts)

- Special thread

- Operating tools

- Lubricant

- Thread restoration tools

- Countersink

- Step drills

- Thread gauges

-

Thread standards

- Twist drill bits

- Drill chucks

- BaerCoil/BaerFix

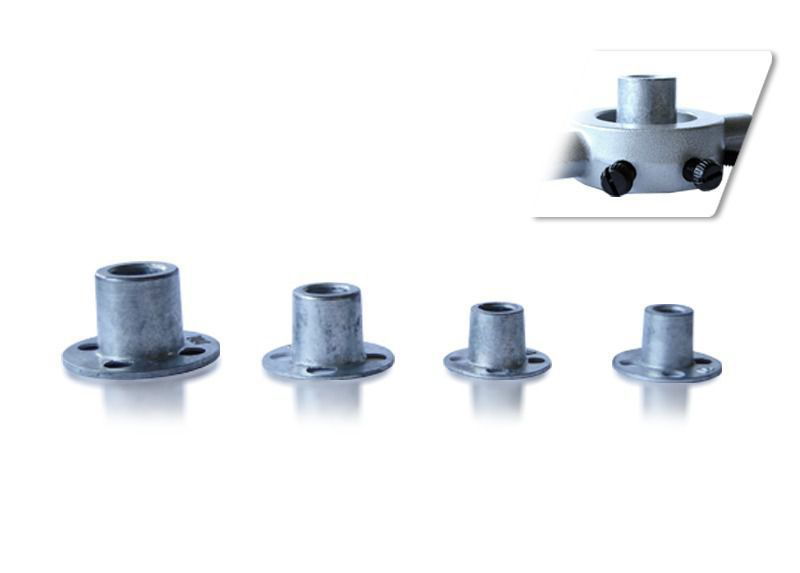

Cutting die guides made of free-cutting steel

In stock

Express shipping available

Cutting die-Guides made of free cutting steel

As a do-it-yourselfer, you have probably already experienced that sometimes it is simply faster to do it by hand. But precision is elementary with a die guide . Sure, we love our powerful machines and the scope they give us. But every now and then we come across a case where it feels like shooting at a sparrow with a cannon. You just want to quickly cut an external thread on a bolt? Before you have set up and adjusted the machine, you are already finished with the die stock in your hand.

But of course it's not quite that simple. Because working by hand also has its disadvantages. Especially when it comes to cutting external threads, precision is enormously important. And if you ruin bolts and thread cutting die when cutting by hand, the time saved is quickly wasted. So what can you do?

This is where we like to bring die guide into play. At first glance, the die guide looks pale and inconspicuous, but it quickly turns out to be an important tool. Thanks to its special design, the die guide simply bridges the precision gap between die holder and the machine - and can thus be decisive for your decision to work more by hand again. So let's take a closer look at the small part with the big effect.

Die guide function - we explain

The die guide is one of those parts that you can't always immediately identify when you look into an untidy toolbox. So, of course, we don't want to accuse you of chaos at case. But take a look and see if there might already be a die guide in your collection!

Because visually, the die guide doesn't look like much at first. It is a short tube that ends in a brim. A bit like a cylinder, except that it has no chip holes. Thanks to the brim, the die guide can be inserted into a die stock without jerking. The tube is used to hold the bolt in which you want to cut the external thread. When you use the die guide with a cutting die it is automatically guided along the longitudinal axis of the bolt. And your external thread becomes wonderfully precise and straight.

Everything on track: the performance of the die guide

What is particularly inconvenient about thread cutting by hand is the fact that we humans are not perfect. The machine only moves where it should. Placing a thread cutting die plumb is no problem for it. For humans, it is much more difficult to keep the cutting die really straight. Even with a steady hand and a good eye, you will hardly achieve perfect results. That is why aids such as die guides come in so handy.

But why does the cutting die have to be set plumb in the first place? The reason is that the external thread is very susceptible to cutting. Once you have set it incorrectly, it is almost impossible to correct it. If the working direction is not exactly parallel to the longitudinal axis, the thread becomes crooked. This not only ruins the bolt, but in the worst case you also damage the thread cutting die. That is why we at BAER, your tap manufacturer, recommend the use of a die guide.

Fie guide function: With the die guide to the perfect thread

Using the die guide is not difficult and does not require any special knowledge. Insert the guide into the die stock with the tube facing downwards. Next, as usual, place your cutting die in the holder. Make sure that the chip holes in the cutting die are congruent with those in the die guide . This is the only way to ensure optimum chip evacuation. Tighten the locking screws to fix the cutting die. In this way, the guide is also automatically held in place and cannot slip.

You should chamfer the bolt all around before cutting the external thread. Then put some cutting paste on it as a lubricant. Now the prepared holder with thread cutting die and die guide comes into play. Put the small tube of the die guide over the bolt. If everything fits well, it is now impossible for you not to keep the cutting die holder plumb.

Now you can start to cut the thread with the thread cutting die under gentle pressure. A few turns will do for now. At this point you can turn the thread cutting die back again and remove the die guide from the die stock. Due to the successful chamfer, the thread cutting die will automatically sit plumb on the second round and you can easily finish cutting the external thread this time without die guide.

Tips for buying die guides

Well, have we convinced you of the advantages of die guides? Before you run out and buy some yourself, here are a few things you should bear in mind.

Not every die holder is designed to use a guide for cutting die . After all, the die guide takes up a little space that is otherwise reserved for the cutting die. So make sure that your die stock can be used together with a guide for thread cutting dies.

Furthermore, you should choose the right size of die guide. Like the cutting die itself, the guides for cutting die are only suitable for cutting a certain thread size. Die guides are often offered in sets with different sizes, so you can easily cover a wider range of thread sizes with one purchase.

High-quality material is also advantageous for guides for cutting dies. It is therefore not advisable to make your own die guides. Instead, you should use guides made of free-cutting steel, which offer a special fitting accuracy. They are also very stable and durable - so you have a perfect aid for cutting external threads at your side for many years that will not let you down.

Of course, you can also find high-quality die guides in our online shop. Make your work easier and cut perfectly plumb external threads with guides for thread cutting dies from BAER! And if you have any questions about the application or would like more detailed information before making a purchase, please feel free to contact us.