-

Taps & Dies

-

Thread standards

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- UN - amer. with special pitch

- UNS - amer. with special pitch

- BSW - british coarse thread

- BSF - British fine thread

- Tr - trapezoidal thread

- Rd - knuckle thread

- NPT - amer. taper pipe thread

- NPTF - amer. taper pipe thread

- NPS - amer. cyl. pipe thread

- Rc (BSPT) - taper pipe thread

- Rp (BSPP) - cyl. pipe thread

- Vg - valve thread

- BA - brit. assn. Thread

- BSB - BSC - brit. std. thread

- W - taper gas cylinder valves

- Electrical and cable thread

- Bicycle and pedal thread

- Photo and C-Mount Thread

- Mini and nano threads (< 2mm)

- PG - steel conduit thread

- S - buttress thread

- RMS - microscope thread

- MJ, UNJC, UNJF - Aviation

- STI thread (thread inserts)

- Special thread

- Operating tools

- Lubricant

- Thread restoration tools

- Countersink

- Step drills

- Thread gauges

-

Thread standards

- Twist drill bits

- Drill chucks

- BaerCoil/BaerFix

Trapezoidal taps from BAER - how to get things moving

Toolfinder

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

Tr – trapezoidal thread

When thinking about threads, most people initially think of screws and nuts – applications where threads primarily fasten components together. In addition to this group of fastening threads, however, there is another category: power transmission threads. Here, the focus is not on clamping force but on the transmission of movement. The most well-known power transmission thread is the trapezoidal thread, which is produced using a trapezoidal tap. With trapezoidal taps from BAER, you are perfectly equipped.

Everything you need to know about the trapezoidal thread according to DIN 103

The trapezoidal thread owes its name to its distinctive profile in the shape of an isosceles trapezoid. Compared to threads with a triangular profile, the flanks are thicker and do not taper to a point. The flank angle is 30°. Metric trapezoidal threads are standardized in DIN 103, which defines nominal dimensions and further details.

You can recognize trapezoidal taps by the abbreviation Tr. The designation includes the nominal diameter and the pitch. Tr 14 × 4 therefore denotes a trapezoidal thread with a diameter of 14 mm and a pitch of 4 mm.

From a physical perspective, the trapezoidal thread converts a rotary motion into an axial motion. When the trapezoidal threaded spindle rotates, the nut moves along the axis of the threaded rod. Thanks to the wide flanks and large pitch, trapezoidal threads can absorb high axial forces. In addition, they feature so-called self-locking: the nut or spindle only moves when an external force is applied. This makes an additional brake unnecessary in many applications.

Trapezoidal threads – Our range available for you

Our range includes everything you need for cutting trapezoidal threads. Our tools are made of high-quality high-speed steel and impress with long tool life.

Taps

With precisely manufactured trapezoidal taps from BAER, the work is just as reliable as with metric coarse threads or other standards.

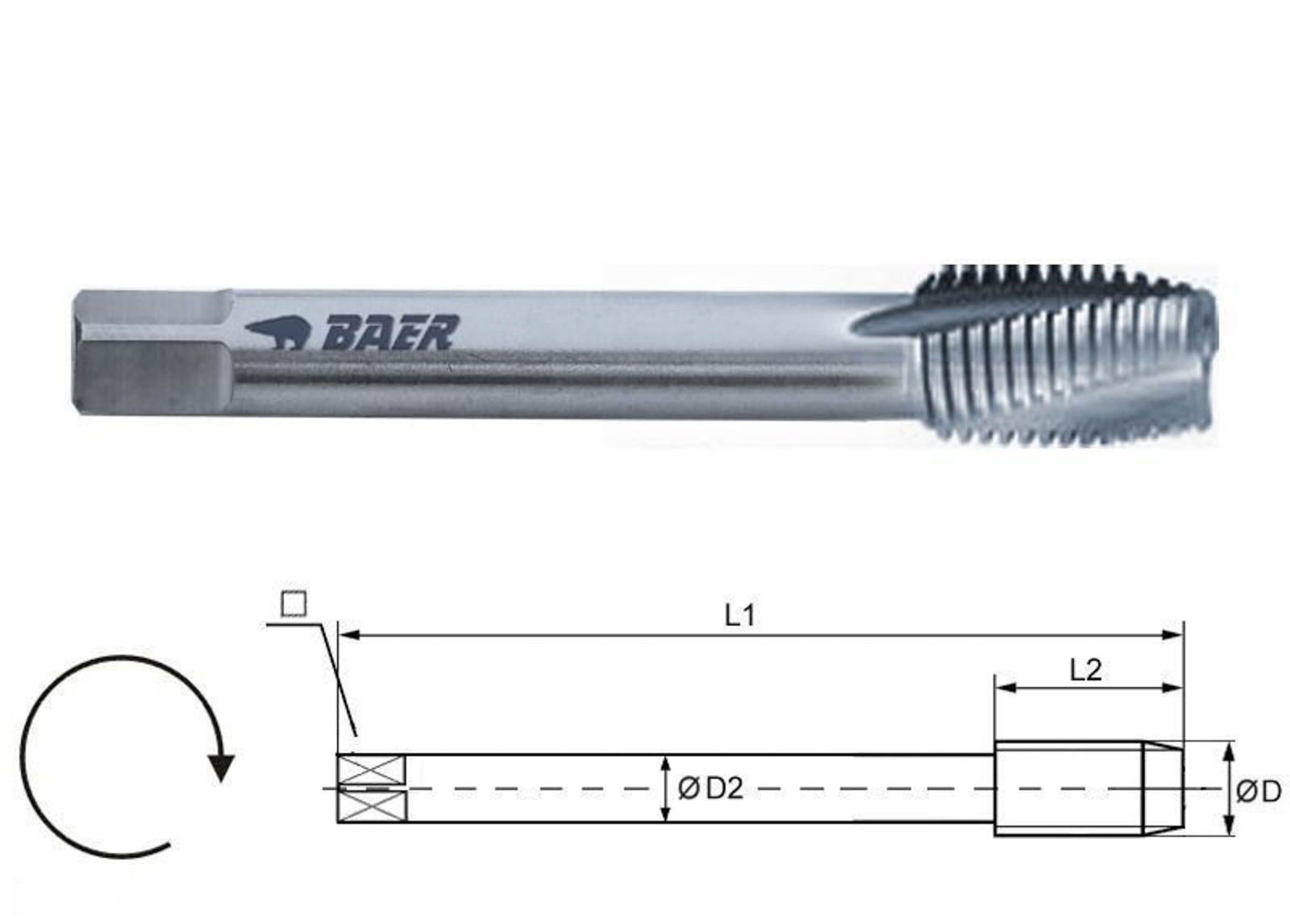

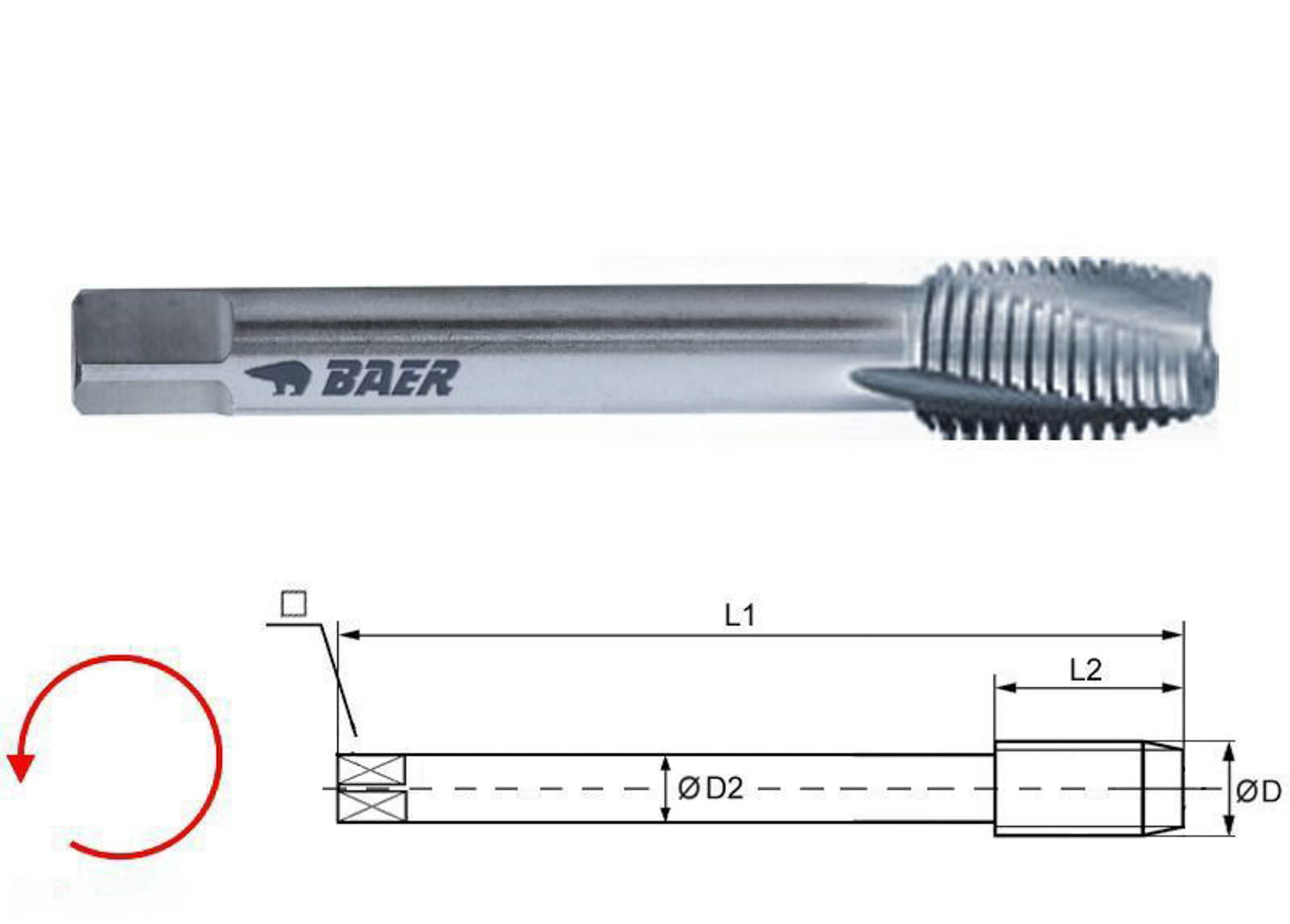

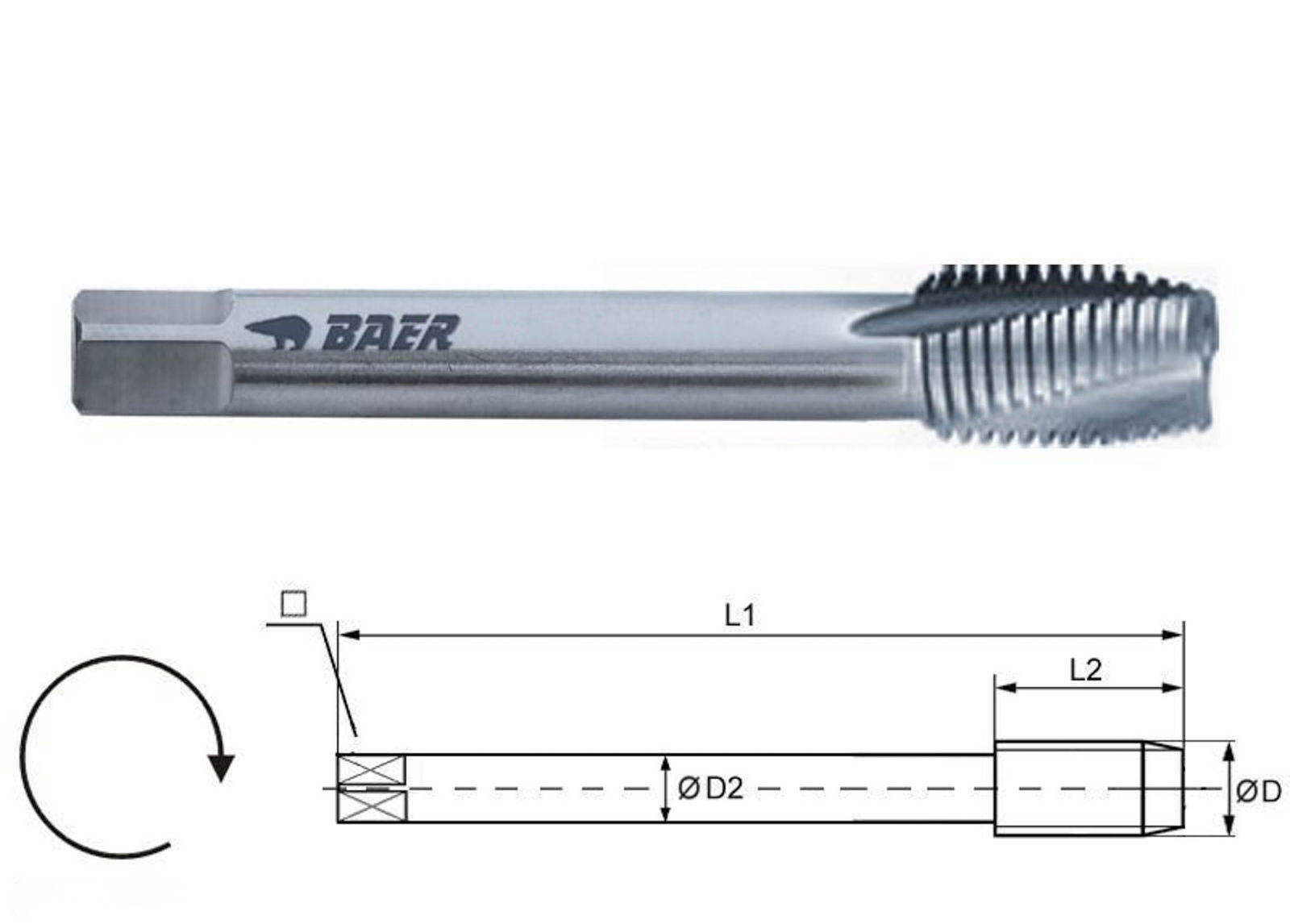

Single-cut taps

Single-cut taps for trapezoidal threads offer particular flexibility. These tools can be used both manually and with machine drives. The thread is produced in a single pass. The tools are suitable for steel and easily machinable materials up to 900 N/mm².

Hand taps

Three graduated tools are used for manual applications: taper tap, intermediate tap and bottoming tap. This optimally distributes the required force. You can purchase the taps individually or in a practical set.

Machine nut taps

For applications with high performance demands in industry and mechanical engineering, we offer machine nut taps. These allow you to produce large quantities in a short time – efficiently and precisely. The tools feature a long extended shank that can accommodate several cut nuts.

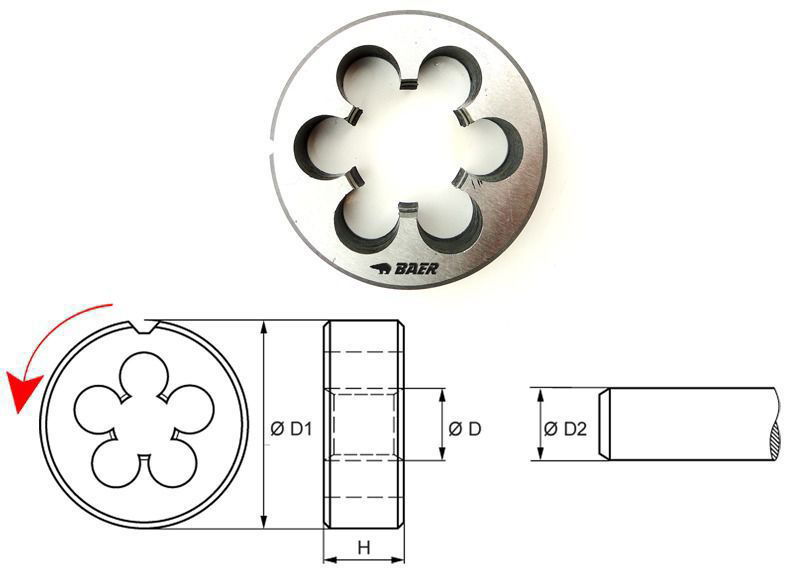

Dies

In addition to nuts, threaded rods also need to be machined precisely. For this purpose, we offer trapezoidal thread dies that can be used both with a die holder and in a machine. Both left-hand and right-hand versions are available.

Thread gauges

Dimensional accuracy is crucial for trapezoidal threads. Over time, wear or damage can cause the tap to no longer comply with strict standard specifications. Plug gauges and ring gauges enable simple and reliable inspection – without elaborate measurements or complex calculations.

Discover tools and accessories for trapezoidal threads now in the BAER online shop!

Cutting metric trapezoidal threads is no problem with high-quality trapezoidal taps. Select your desired size conveniently via our menu or the tool finder on our homepage. All items are manufactured in-house with the greatest care and in many dimensions. Benefit from a wide selection, fast delivery and fair prices. Our customer service is always available by phone, e-mail or via the contact form if you need further information. We look forward to your inquiries!

Do you have any questions? We have the answers!

You'll quickly find the right answers in our FAQ - take a look!