BaerCoil HSSE Machine Tap UNC 10 x 24 STI (oversized for wire thread inserts) - PRO for through holes

In stock

Express shipping available

BaerCoil HSSE Machine Tap UNC 10 x 24 STI (oversized for wire thread inserts) - PRO for through holes

BaerCoil® machine taps are mainly used for thread repair or thread reinforcement in connection with wire thread inserts. This BaerCoil® screw tap can be used to cut a finished thread with oversize as a holding thread for wire thread inserts of the dimension UNC No. 10 x 24 in one operation.

The holding thread for UNC No. 10 x 24 thread inserts is also called STI thread (screw thread insert) or STI thread (in English Screw Thread Insert) and has an oversize so that the normal starting thread UNC No. 10 x 24 is restored after the thread insert is installed.

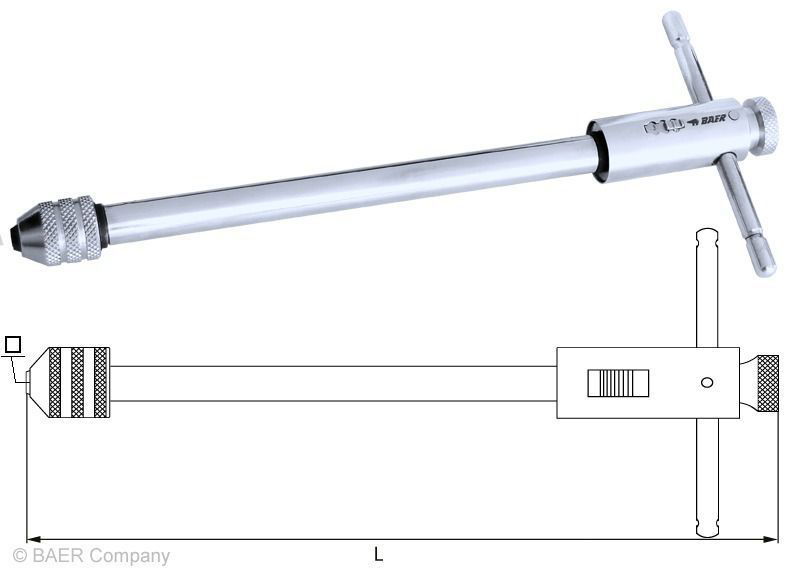

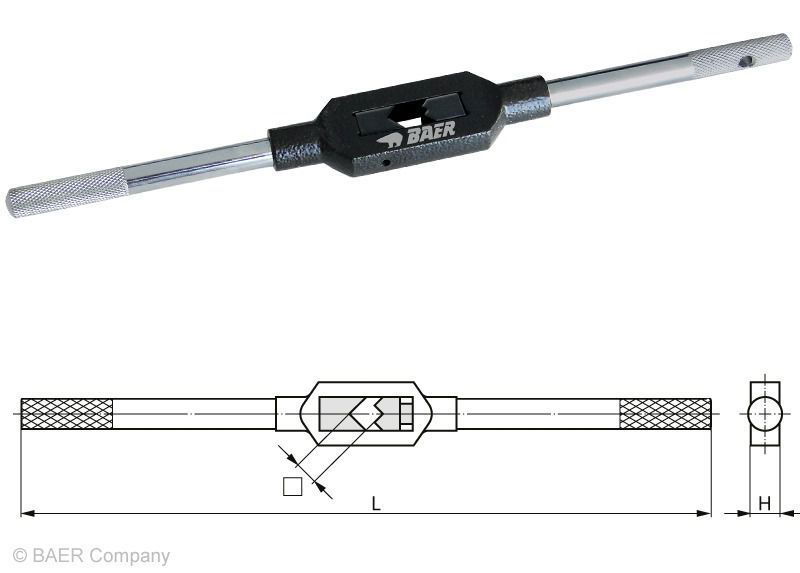

Our machine taps are powerful and reliable taps for efficient machining of threads in one operation on the machine. Machine taps are used primarily in industrial manufacturing. They are suitable for CNC machines, thread cutting machines, cordless drills and pneumatic thread cutting machines, among others. As they are characterised by high efficiency and low production costs, they are often used in series production. The thread is cut by machine in one operation.

This BaerCoil® tap can be used for through holes, as the long gate, the straight groove shape and the spiral point ensure that the chips are transported forward out of the hole

Dimensions

| Diameter |

No. 10 |

|---|---|

| Nominal diameter in inches |

0,244 |

| Nominal diameter in mm |

6,2 |

| Pitch |

24 |

| Pitch in mm |

1,06 |

| Dimension |

UNC No. 10 x 24 EG/STI |

| Square |

5,5 mm |

Characteristics

| Product group |

Screw taps Wire thread inserts - Taps |

|---|---|

| Product type |

BaerCoil screw taps |

| Thread standard |

UNC EG/STI: American Unified National Coarse thread for wire thread inserts according to ASME B1 |

| Tolerance |

2B mod. |

| Direction |

Right |

| Standard |

DIN 371 |

| Tensile strength at room temperature |

up to 900 N/mm² | 27.1 HRC |

| Material |

HSSE bright |

Technical information – Screw taps

5.1 mm

Through hole up to 4 x D

Form B with spiral point

4-5 threads

Chips are removed downwards in the direction of cutting

External cooling and lubrication

HSSE bright

up to 900 N/mm² | 27.1 HRC

2B mod.

Applications

All normal uses for thread repair through-threads.

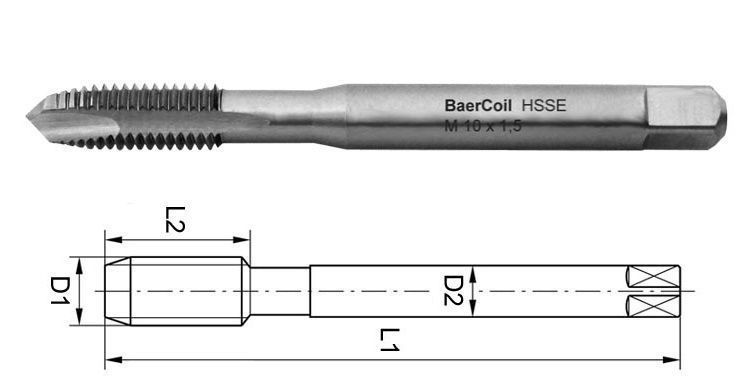

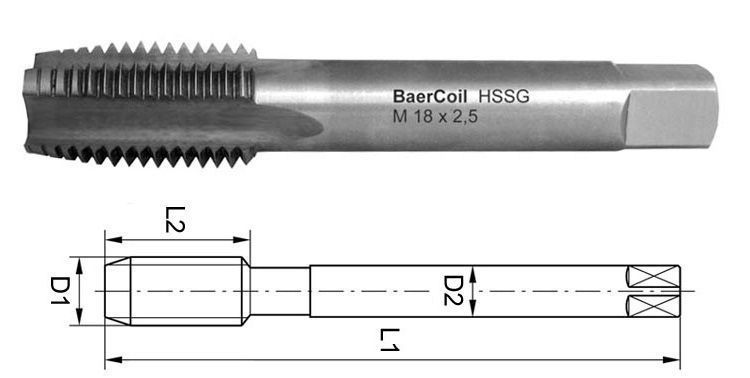

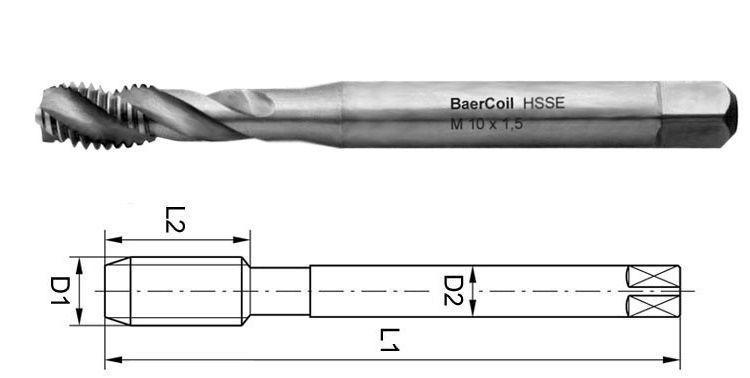

Technical drawing

| D1 |

6,20 mm |

|---|---|

| D2 |

7,0 mm |

| L1 |

80 mm |

| L2 |

17 mm |

| Diameter |

No. 10 |

| Square |

5,5 mm |

Application – Sample materials for taps

| Unalloyed construction steels | Cutting speed vc in m/min | |

|---|---|---|

| 1.0037 | St 37-2 | 5 - 12 |

| 1.0044 | St 44-2 | 5 - 12 |

| 1.0039 | S 235JRG1+CR | 5 - 12 |

| 1.0060 | St 60-2 | 5 - 10 |

| Free-cutting steels | Cutting speed vc in m/min | |

|---|---|---|

| 1.0718 | 9 SMnPb 28 | 5 - 12 |

| 1.0721 | 10 S 20 | 5 - 12 |

| 1.0736 | 9 SMn 36 | 5 - 12 |

| 1.0726 | 35 S 20 | 5 - 10 |

| Cast steel | Cutting speed vc in m/min | |

|---|---|---|

| 1.0420 | GS-38 | 8 - 15 |

| 1.1120 | GS-20 Mn 5 | 5 - 15 |

| 1.5633 | GS-24 Ni 8 | 5 - 12 |

| 1.7379 | GS-18 CrMo 9 10 | 5 - 12 |

| Alloyed construction steels | Cutting speed vc in m/min | |

|---|---|---|

| 1.5415 | 15 Mo 3 | 5 - 12 |

| 1.5622 | 14 Ni 6 | 5 - 10 |

| 1.7335 | 13 CrMo 4 4 | 5 - 10 |

| 1.7715 | 14 MoV 6 3 | 5 - 10 |

Cutting speed vc [m/min] = (Outer diameter * π * speed) / 1000

Rotation speed n [1/min] = (Cutting speed in m/min * 1000) / (Outer diameter * π)

Feedrate programming [mm/min] = speed * pitch

Please note that the above cutting speeds are indicative and must be adjusted depending on lubrication and actuation.

Video instructions

Login