BaerCoil Wire Thread Inserts M 10 x 1.5 - 3.0 D (30 mm) - free running - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts M 10 x 1.5 - 3.0 D (30 mm) - free running - 100 pcs.

BaerCoil® wire thread inserts are the perfect solution for a long-lasting, powerful thread connection and scrap recovery. They also create load-bearing connections in materials with low shear strength and are precise and wear-resistant. wire thread inserts are often used in automotive, electrical engineering, medical technology, lightweight construction and aerospace.

For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) for the wire thread insert is cut. This thread is often also called STI thread (STI=Screw Thread Insert).

BaerCoil® thread inserts ensure optimum power transmission from the bolt to the nut thread - even in lightweight constructions. Due to their flexibility, they can compensate for pitch and angle errors and thus guarantee optimum power transmission. BaerCoil® thread inserts are already important components in the aerospace and automotive industries and help to reduce carrier material and use smaller, shorter bolted joints.

BaerCoil® thread inserts can be shortened, according to the required length, with a side cutter or similar.

Dimensions

| Diameter |

10 |

|---|---|

| Pitch |

1,5 |

| Dimension |

M 10 x 1,5 |

| Length |

3,0 D |

| T (Length when installed) |

30 mm |

| Thread length calculation |

3.0 D means 3 times the diameter: 3 times 10 mm=30 mm The nominal diameter for M 10 is 10 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and thread reinforcement

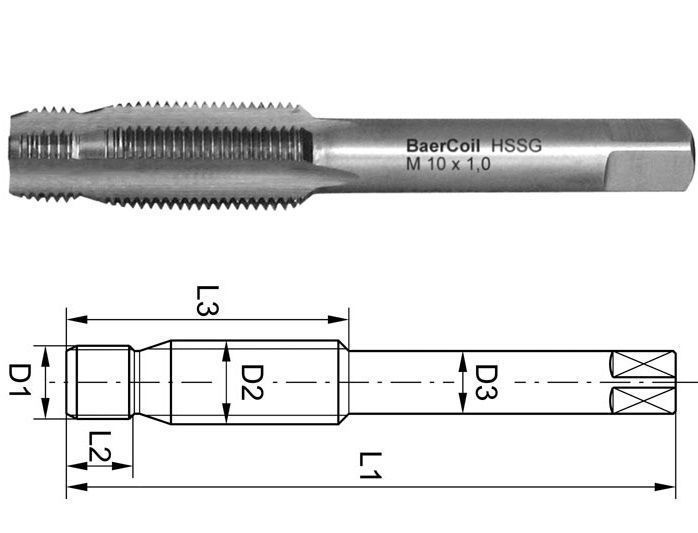

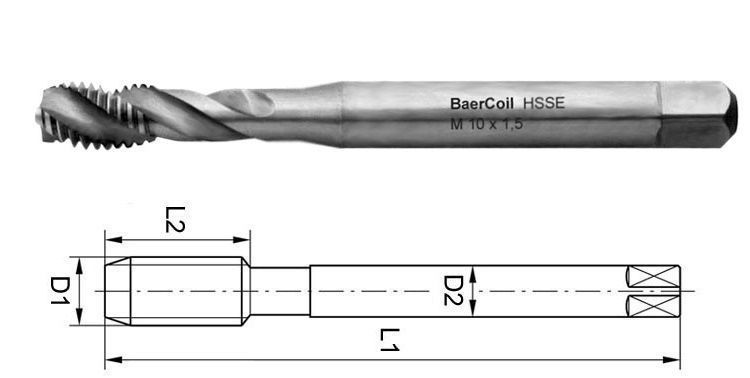

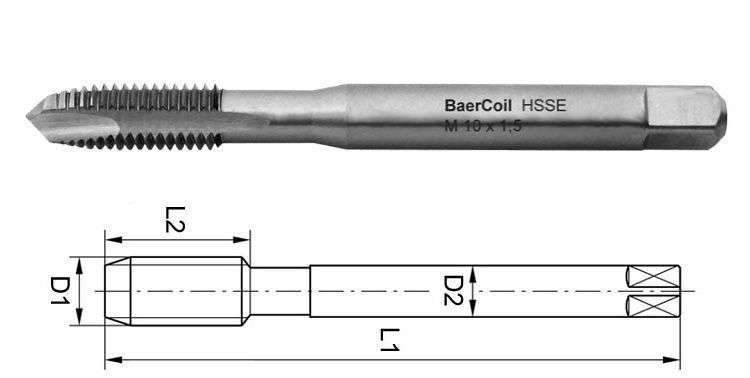

Technical drawing

| Diameter |

10 |

|---|---|

| Length |

3,0 D |

| T (Length when installed) |

30 mm |

| F (Min. - Max. outside diameter of thread insert) |

11,74 mm - 12,50 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

35,25 mm |

| D (minimum depth of the core hole, without tip) |

36,75 mm |

Video instructions

Further information

Product data sheet

Safety instructions

Login