BaerCoil Wire Thread Inserts M 4 x 0.7 - 1.5 D (6 mm) - free running - Inconel X750 - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts M 4 x 0.7 - 1.5 D (6 mm) - free running - Inconel X750 - 100 pcs.

BaerCoil® wire thread inserts are the perfect solution for a long-lasting, powerful thread connection and scrap recovery. They also create load-bearing connections in materials with low shear strength and are precise and wear-resistant. wire thread inserts are often used in automotive, electrical engineering, medical technology, lightweight construction and aerospace.

The BaerCoil® thread insert is the perfect solution for damaged threads. For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) for the wire thread insert is cut.

BaerCoil® thread inserts ensure optimum power transmission from the bolt to the nut thread - even in lightweight constructions. Due to their flexibility, they can compensate for pitch and angle errors and thus guarantee optimal force transmission. BaerCoil® thread inserts are already important components in the aerospace and automotive industries and help to reduce carrier material and use smaller, shorter bolted joints.

BaerCoil® thread inserts can be shortened, according to the required length, with a side cutter or similar.

Dimensions

| Diameter |

4 |

|---|---|

| Pitch |

0,7 |

| Dimension |

M 4 x 0,7 |

| Length |

1,5 D |

| T (Length when installed) |

6 mm |

| Thread length calculation |

1.5 D means 1.5 times the diameter: 1.5 times 4 mm=6 mm The nominal diameter for M 4 is 4 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1150 N/mm² |

| Material |

Inconel X750 (NiCr15Fe7TiAl, material no.: 2.4669) |

| Temperature resistance |

550°C long-term 750°C short-term |

Applications

- Aerospace

- Turbocharger

- Aircraft engines

- Turbines

- Thermal power plants

Attributes

- high thermal resistance

- high corrosion protection

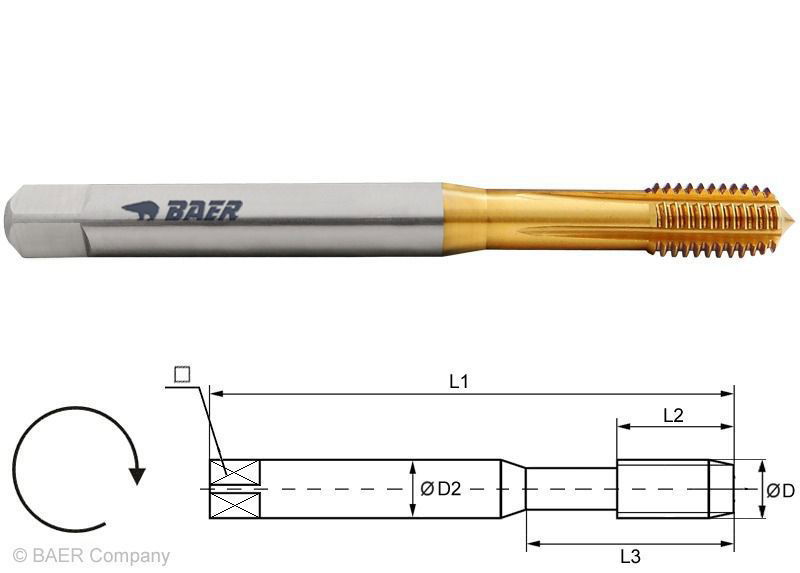

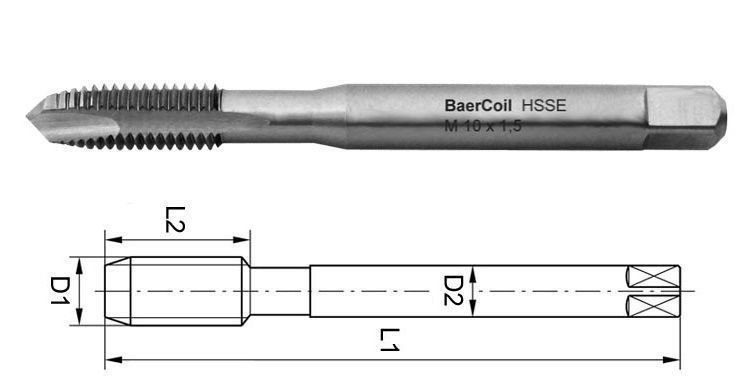

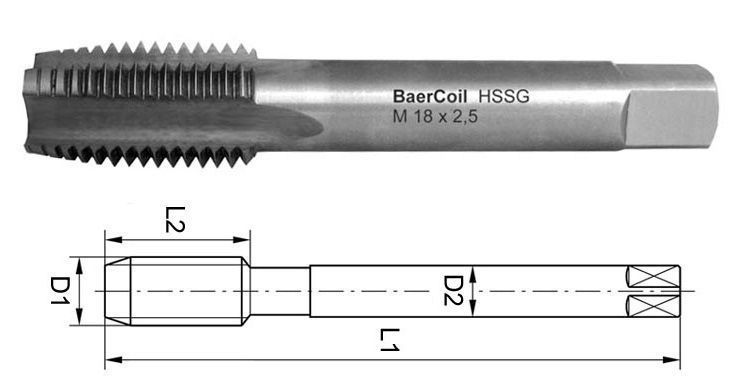

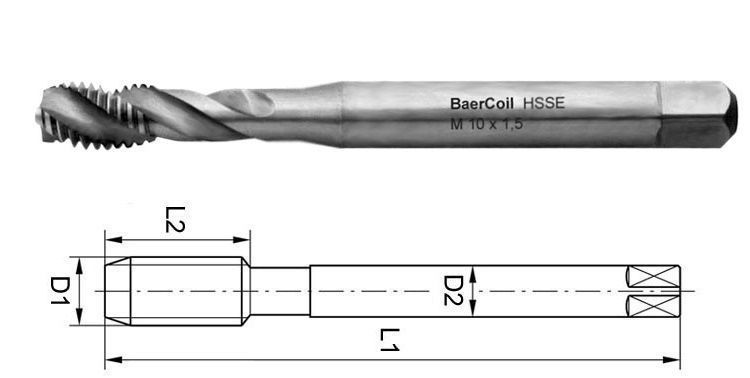

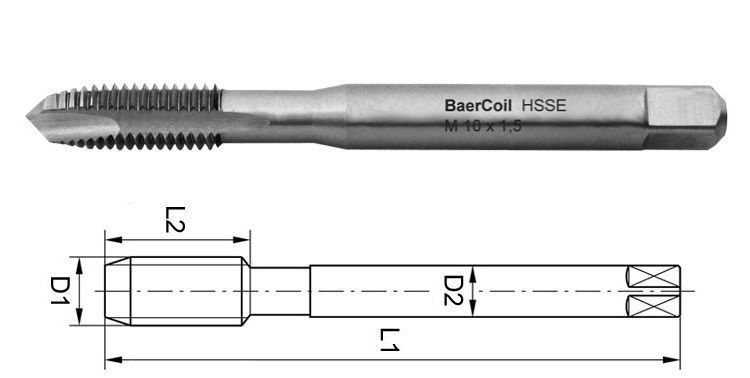

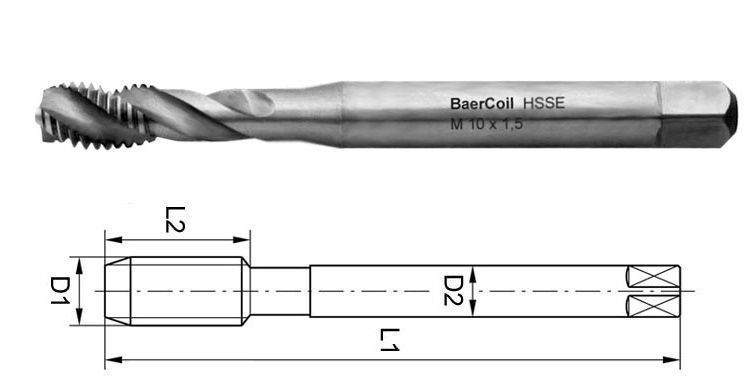

Technical drawing

| Diameter |

4 |

|---|---|

| Length |

1,5 D |

| T (Length when installed) |

6 mm |

| F (Min. - Max. outside diameter of thread insert) |

4,83 mm - 5,60 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

8,45 mm |

| D (minimum depth of the core hole, without tip) |

9,15 mm |

Video instructions

Further information

Product data sheet

Safety instructions

Login