BaerCoil Wire Thread Inserts M 5 x 0.8 - 2.0 D (10 mm) - free running - AISI 316 - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts M 5 x 0.8 - 2.0 D (10 mm) - free running - AISI 316 - 100 pcs.

BaerCoil® thread inserts are the best solution for all your repair needs! With them you can create long-lasting and powerful connections. These inserts also ensure that you have no waste and recycle everything. The inserts are precise and wear resistant - your screw will stay firmly in place without the thread insert slipping.

BaerCoil® thread inserts are the perfect solution for damaged threads. They are drilled out and a new STI thread (screw thread insert) is cut for the wire- thread insert. This thread is often also called STI thread (STI=Screw Thread Insert). Then the BaerCoil® thread insert is screwed into the old thread and the workpieces are screwed on again. With BaerCoil® thread inserts, the thread produced is significantly more stable than the original thread.

BaerCoil® thread inserts are perfect for applications where a balanced distribution of forces is required. They can withstand both static and dynamic loads and help save support material.

BaerCoil® thread inserts can be shortened to the required length with a side cutter or similar.

Dimensions

| Diameter |

5 |

|---|---|

| Pitch |

0,8 |

| Dimension |

M 5 x 0,8 |

| Length |

2,0 D |

| T (Length when installed) |

10 mm |

| Thread length calculation |

2.0 D means 2 times the diameter: 2 times 5 mm=10 mm The nominal diameter for M 5 is 5 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V4A (AISI 316, X5CrNiMo17-12-2, Material No.: 1.4401) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

Applications in seawater and chlorinated water

Attributes

- improved corrosion resistance

- reduced thread friction

- for high-alloy CrNi steel screws

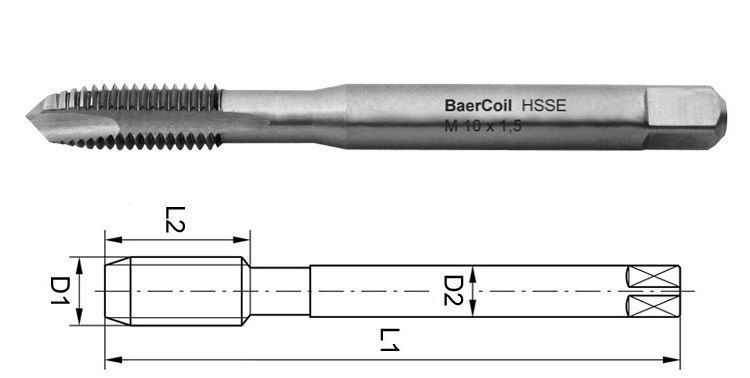

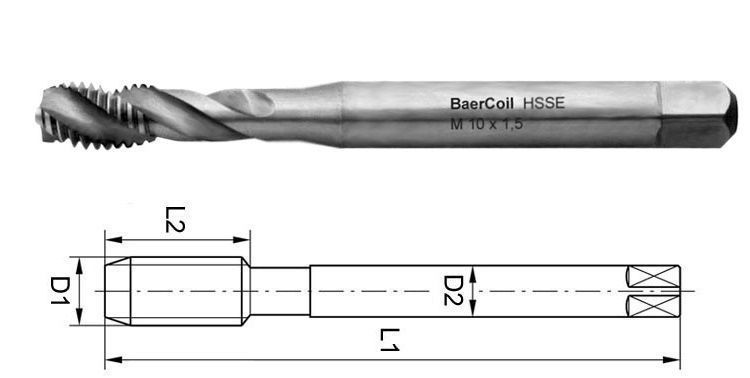

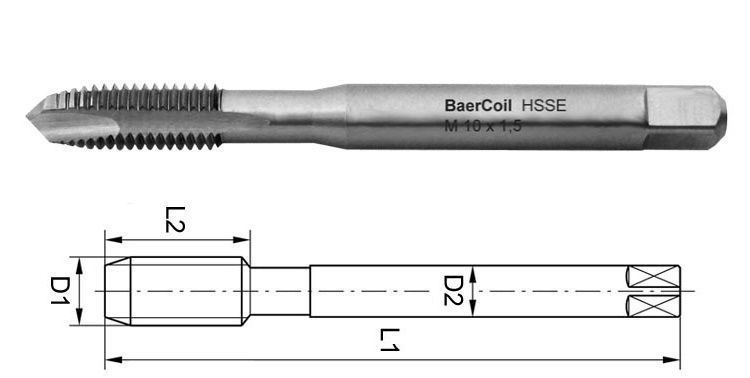

Technical drawing

| Diameter |

5 |

|---|---|

| Length |

2,0 D |

| T (Length when installed) |

10 mm |

| F (Min. - Max. outside diameter of thread insert) |

5,94 mm - 6,80 mm |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

12,80 mm |

| D (minimum depth of the core hole, without tip) |

13,60 mm |

Video instructions

Further information

Product data sheet

Safety instructions

Login