BaerCoil Wire Thread Inserts UNC 1/2 x 13 - 3.0 D (38.1 mm) - free running - 100 pcs.

In stock

BaerCoil Wire Thread Inserts UNC 1/2 x 13 - 3.0 D (38.1 mm) - free running - 100 pcs.

BaerCoil® thread inserts are the best solution for all your repair needs! With them you can create long-lasting and powerful connections. These inserts also ensure that you have no waste and recycle everything. The inserts are precise and wear resistant - your screw will stay firmly in place without the thread insert slipping.

The BaerCoil® thread insert is the perfect solution for damaged threads - with the same nominal diameter! For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) for the wire thread insert is cut. Often this thread is also called STI thread (STI=Screw Thread Insert).

BaerCoil® thread inserts are perfect for applications where a balanced distribution of forces is required. They can withstand both static and dynamic loads and help save support material.

BaerCoil® thread inserts can be shortened to the required length with a side cutter or similar.

Dimensions

| Diameter |

1/2 |

|---|---|

| Pitch |

13 |

| Dimension |

UNC 1/2 x 13 |

| Length |

3,0 D |

| T (Length when installed) |

38,1 mm |

| Thread length calculation |

3.0 D means 3 times the diameter: 3 times 12.7 mm=38.1 mm The nominal diameter at UNC 1/2 is approx. 12.7 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

UNC: American Unified National Coarse thread according to ANSI B1.1 |

| Direction |

Right |

| Type |

free running |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and thread reinforcement

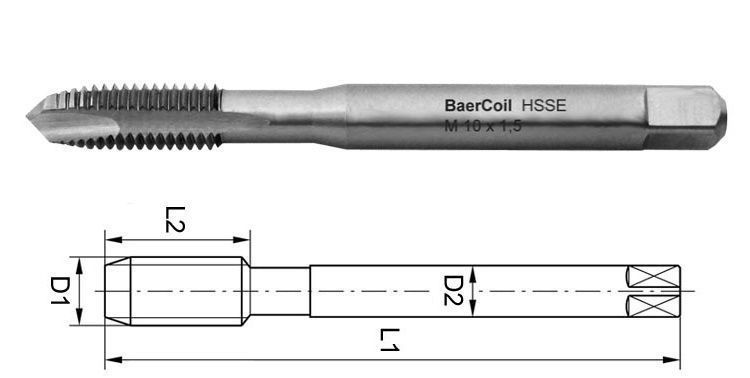

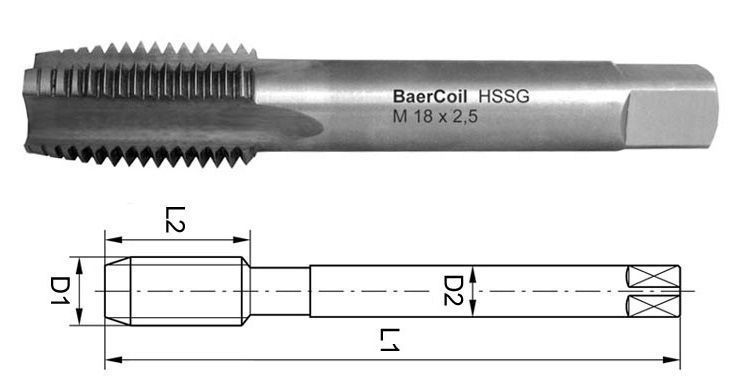

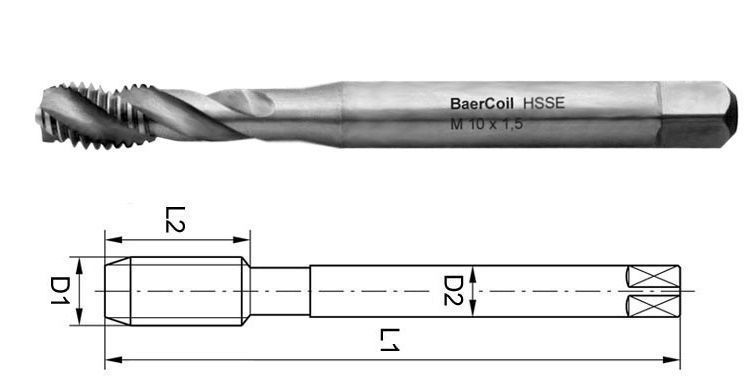

Technical drawing

| Diameter |

1/2 |

|---|---|

| Length |

3,0 D |

| T (Length when installed) |

38,1 mm |

| F (Min. - Max. outside diameter of thread insert) |

0,588 '' - 0,622 '' |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

1,769 '' |

| D (minimum depth of the core hole, without tip) |

1,846 '' |

Video instructions

Further information

Product data sheet

Safety instructions

Login