BaerCoil Wire Thread Inserts UNC No. 10 x 24 - 1.5 D (7.24 mm) - screw grip (screw locking) - 100 pcs.

In stock

Express shipping available

BaerCoil Wire Thread Inserts UNC No. 10 x 24 - 1.5 D (7.24 mm) - screw grip (screw locking) - 100 pcs.

BaerCoil® wire thread inserts are the perfect solution for a durable, powerful threaded connection and With the BaerCoil® wire thread inserts you create perfect, durable and powerful threaded connections. At the same time, the use of wire thread inserts allows for scrap recovery and load-bearing connections in materials with low shear strength. This is why wire thread inserts is often used in automotive, electrical engineering, medical technology, lightweight construction and aerospace.

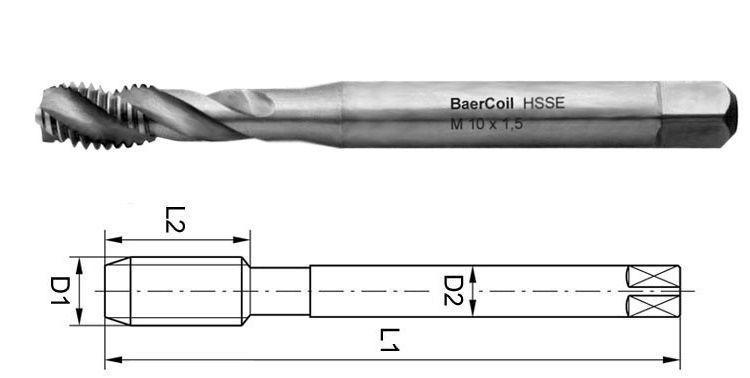

For thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) for the wire thread insert is cut. This thread is often also called STI thread (STI=Screw Thread Insert).

BaerCoil® thread inserts ensure optimum power transmission from the bolt to the nut thread, even in lightweight constructions. Today they are already an important component in aviation and vehicle construction.

BaerCoil® screw-locking thread inserts | Type "screw grip " - All advantages at a glance

With the self-clamping "screw grip" thread inserts, your construction remains stable - regardless of shocks, constant vibrations or movements. The screw-locking BaerCoil® thread inserts complement the properties of the "free running" connection and have a clamping effect on the flanks of the screwed-in screw due to their polygonally shaped windings. Please use only screws of a higher strength class for this purpose, as an elastically resilient frictional connection is created. The clamping torques are comparable with the specifications in DIN 267 Part 15 and ISO 2320. Please note that special insertion tools with reduced diameters are required for screw grip inserts.

BaerCoil® thread inserts can be shortened if necessary, according to the required length, with a side cutter or similar. It should be noted that the thread inserts with screw locking have a polygonal winding approximately in the middle of the insert. This must not be removed when shortening in order to maintain the screw locking effect.

Dimensions

| Diameter |

No. 10 |

|---|---|

| Pitch |

24 |

| Dimension |

UNC No. 10 x 24 |

| Length |

1,5 D |

| T (Length when installed) |

7,24 mm |

| Thread length calculation |

1.5 D means 1.5 times the diameter: 1.5 times 4.83 mm=7.24 mm The nominal diameter at UNC No. 10 is approx. 4.83 mm |

Characteristics

| Product group |

Wire thread inserts |

|---|---|

| Product type |

BaerCoil wire thread inserts |

| Thread standard |

UNC: American Unified National Coarse thread according to ANSI B1.1 |

| Direction |

Right |

| Type |

screw grip (screw locking) |

| Tensile strength at room temperature |

>1400 N/mm² |

| Material |

Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance |

315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and thread reinforcement

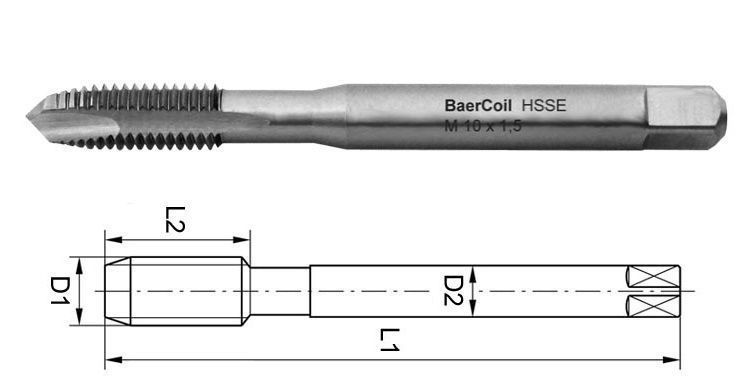

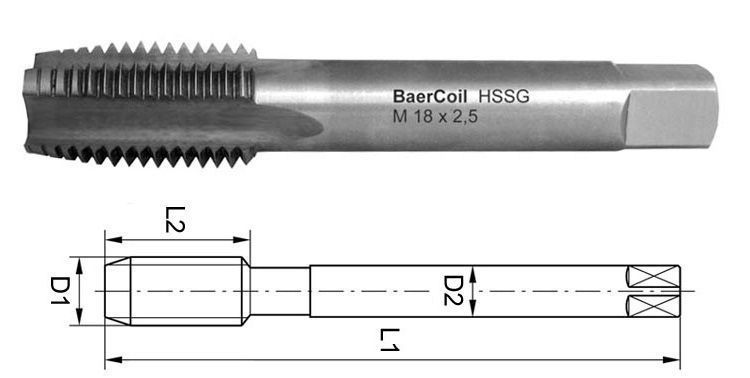

Technical drawing

| Diameter |

No. 10 |

|---|---|

| Length |

1,5 D |

| T (Length when installed) |

7,24 mm |

| F (Min. - Max. outside diameter of thread insert) |

0,238 '' - 0,259 '' |

| P (depth) |

The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) |

0,431 '' |

| D (minimum depth of the core hole, without tip) |

0,472 '' |

Video instructions

Further information

Product data sheet

Safety instructions

Login