Thread standards from BAER

Thread types and thread sizes

Thread standards

Strong as an BAER and versatile in thread machining

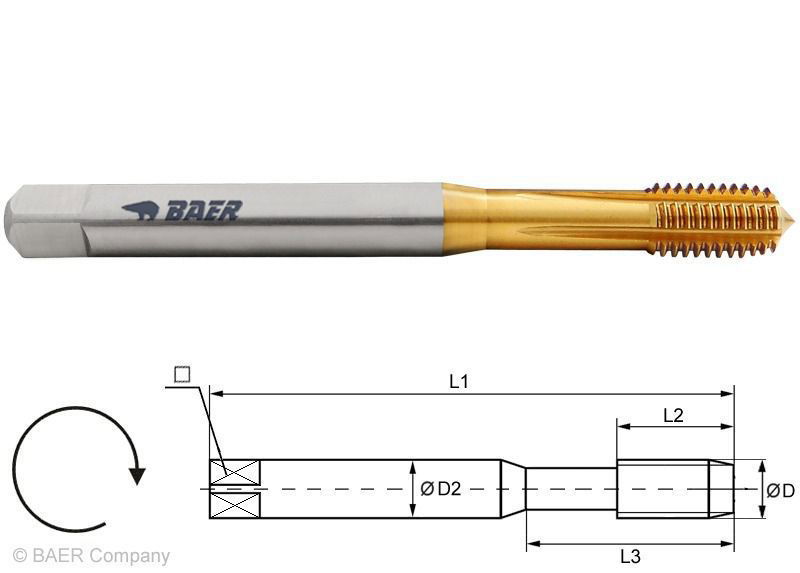

As a customer, you benefit from our many years of experience in thread machining. For over 40 years, we have established ourselves as an independent family business and can help you with any special case. In our extensive range you will find screw taps for machine and manual use. You will receive genuine top quality in all designs and for different materials at an excellent price/performance ratio. Screw taps from professionals for professionals.

Toolfinder

Toolfinder

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

Topseller

Tap according to thread standards

Accessories

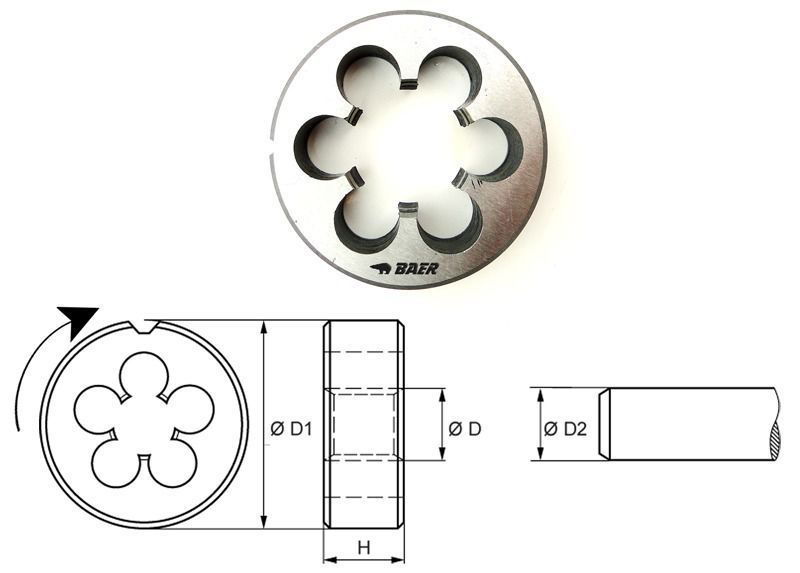

There is not only "the thread", but through many parallel developments, different types of threads have emerged. In order for the screw (with external thread) and nut (with internal thread) to engage with each other, both must be designed to fit. In order to use standards in design, these parallel developments were combined in standards and today offer a real variety of different thread standards. These differ in part by their intended use and their particular thread profiles. That is why we at BAER have a large repertoire of different variants ready for you.

Thread standards: Classification into fastening and movement threads

The most commonly used type of thread is used for fastening components. It is popular in all constructions and, contrary to e.g. riveting and gluing, can often be loosened and reassembled. Threads are therefore found in almost all fastenings that need to be able to be assembled and disassembled. The common thread standards fastening threads include the metric DIN 13 thread , the American UNC thread, the British Whitworth thread and the pipe thread sanitary and hydraulic threads, all of which you can buy in our shop.

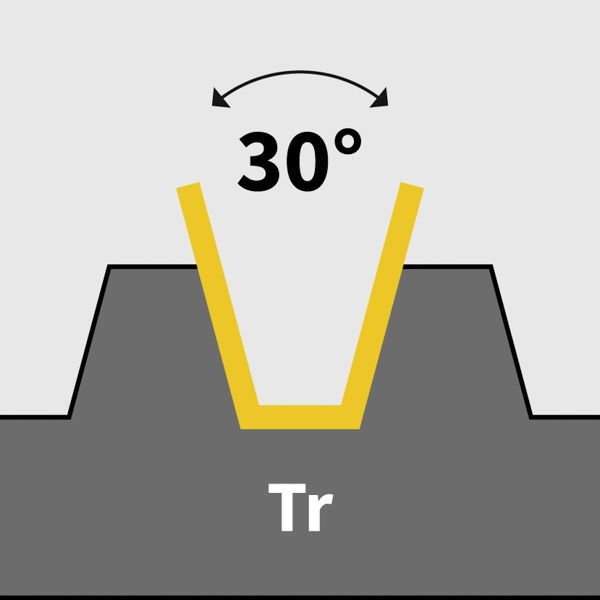

This is to be distinguished from the types of threads and thread standards, which are used to transmit movements. For example, you will find them in spindles to cover a certain distance by rotation. Examples are also found in many types of presses, where often trapezoidal thread DIN 103 are used, because their very coarse thread profile allows them to transmit an exceptionally high force and they are wear-resistant.

A special feature of thread standards movement threads is that they are also often multi-start. If the thread has two threads, for example, twice the distance is covered with one turn of the thread compared to a normal single-start thread.

Significance of nominal diameter, pitch diameter and core diameter in the different thread types and thread standards

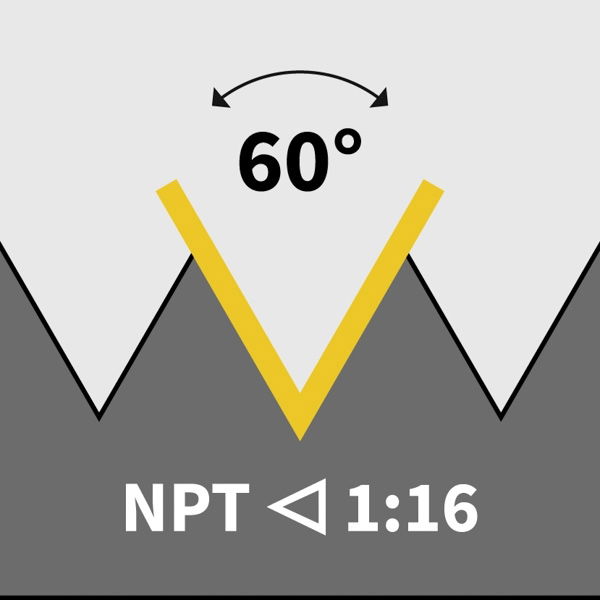

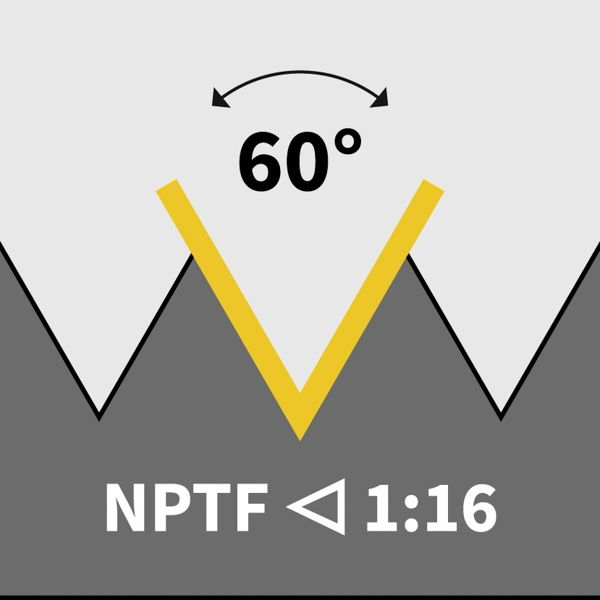

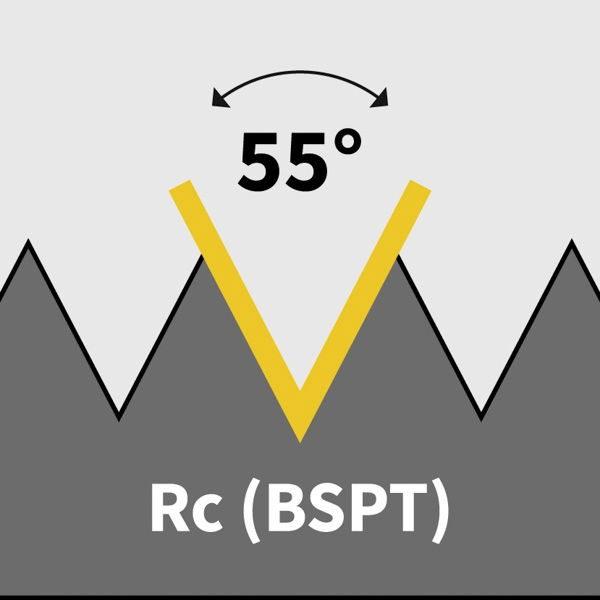

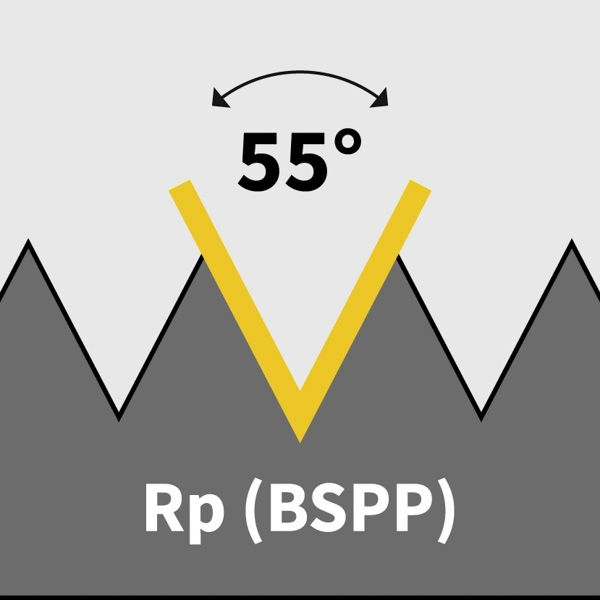

In the very many existing and still used thread standards, a distinction is always made in the first step according to the diameter. Most thread profiles have cylindrical threads and therefore have only one nominal diameter, pitch diameter or core diameter. Only relatively few threads are tapered and are therefore determined according to the smallest and largest diameters, as well as the taper ratio. The most common taper threads included the NPT thread American National Pipe Taper Thread, the BPST British Standard Pipe Taper Thread and the metric taper thread. Get an overview of the numerous models of thread standards from BAER Tools - we offer the best quality at a fair price.

With most thread standards, the thread is first designated according to its nominal diameter. The nominal diameter is mostly the rounded outer diameter of the thread. So if you take a normal metric M 10 screw, its outer diameter is approx. 10 mm and is therefore also called nominal diameter.

The pitch diameter is the average diameter between the outer diameter and the core diameter. It therefore depends on the height of the thread tips. If you look at the thread from the side, the pitch diameter is a theoretical cylinder that divides the thread in the middle into peaks and valleys of equal height.

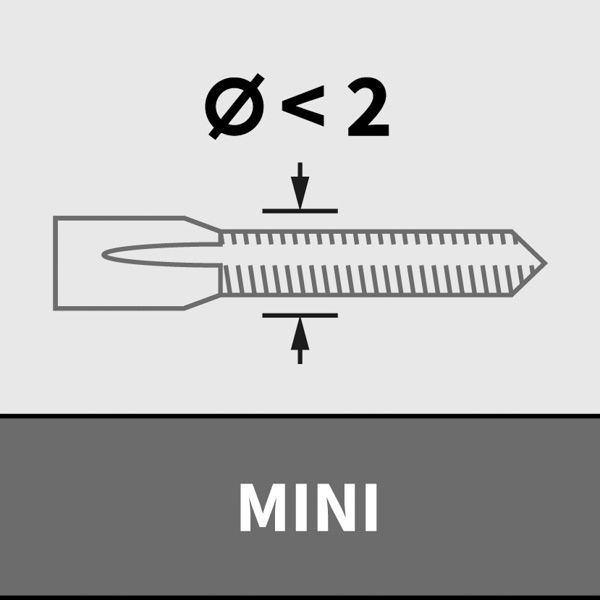

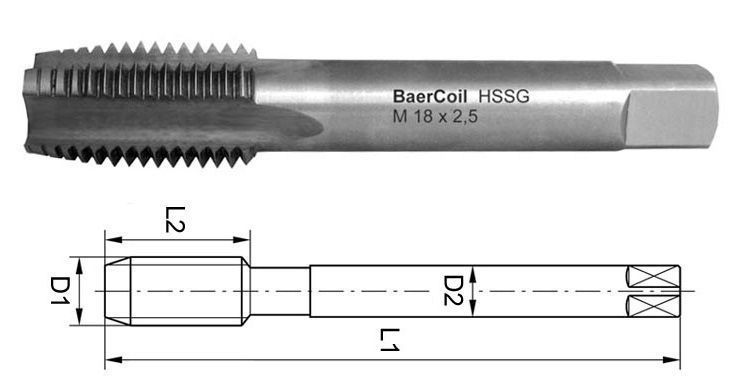

The core diameter of the thread is the smallest diameter. If you want to cut a internal thread with a tap, more precisely screw tap, you first drill the core hole. This pre-drilled core hole corresponds to the smallest diameter of the thread.

Pitch, threads per inch and flank angle - Important terms for thread standards

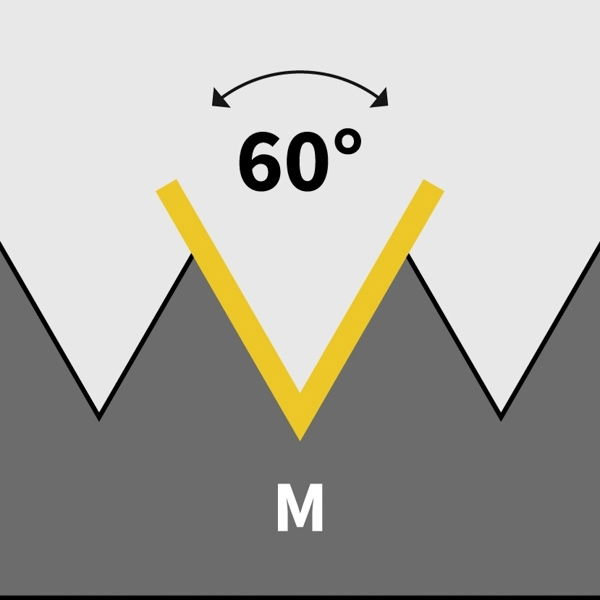

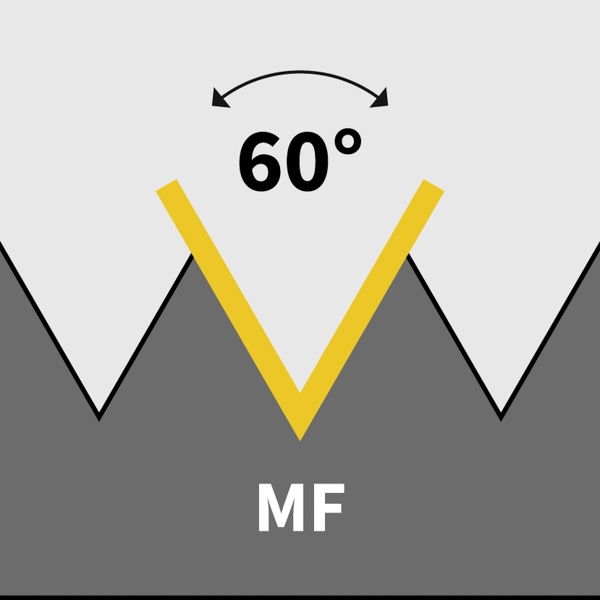

Together with the diameters, the thread standard and thus the thread profile is determined by the pitch, or the threads per inch and the thread angle.

As with the nominal diameter of the thread profile, the pitch is also given in millimetres for metric threads and in inches for imperial threads. To help you find your way around our range, here are a few explanations:

For thread standards, which follow the metric system, the distance from one thread tip to the next thread tip is measured and designated in millimetres. For standard threads M 5 x 0.8, the pitch between one thread tip and the next thread tip is 0.8 mm. If you have a thread profile with a fine thread, the thread pitch, i.e. the distance from one thread tip to the next thread tip, is smaller.

On the other hand, for thread standards, which follows the inch system, the number of thread tips per 1" inch thread length (25.4 mm) is specified. So if the specification is 20 threads per inch (TPI), 20 threads, or more precisely 20 thread tips, are to be counted on the distance of one inch of thread profile. This corresponds to a pitch of 1.27 mm, since 25.4 mm thread length has 20 thread tips.

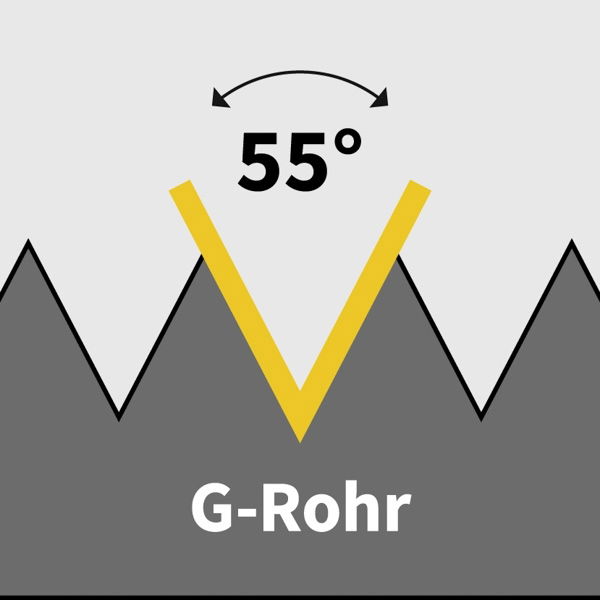

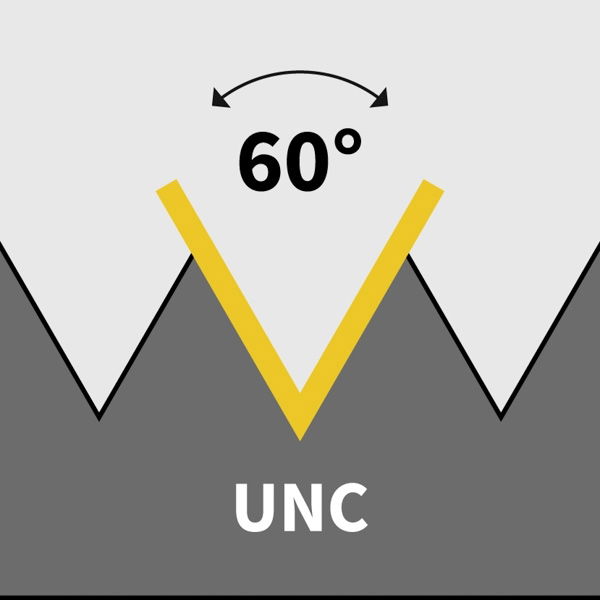

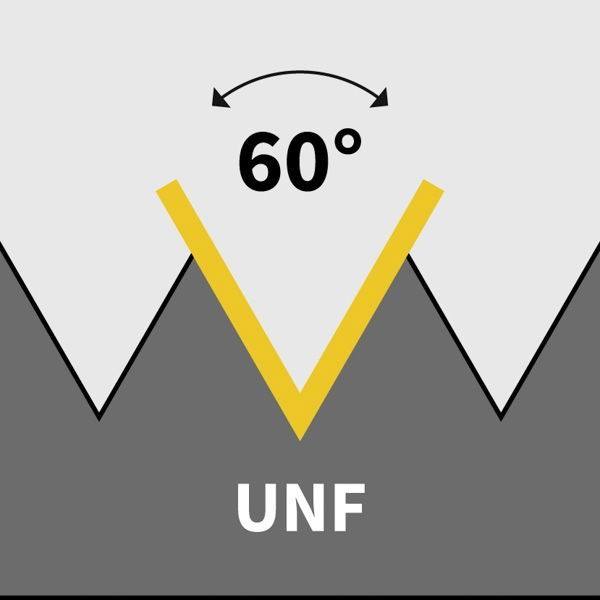

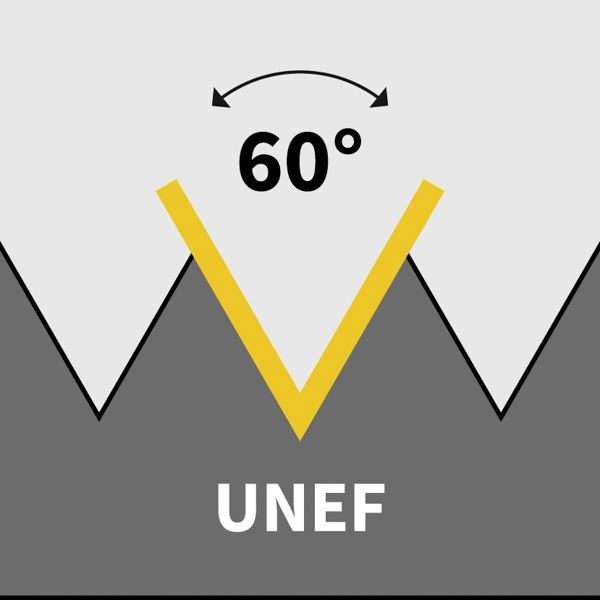

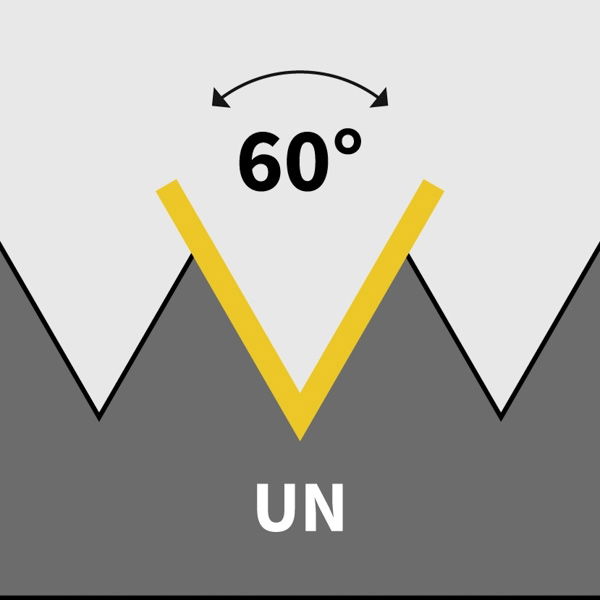

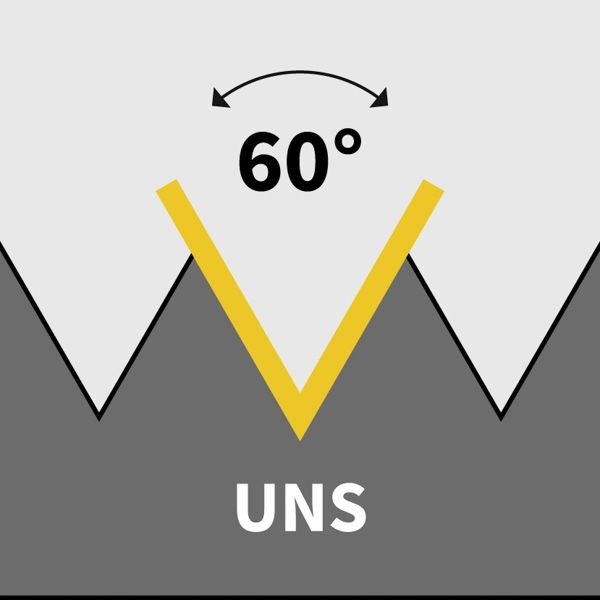

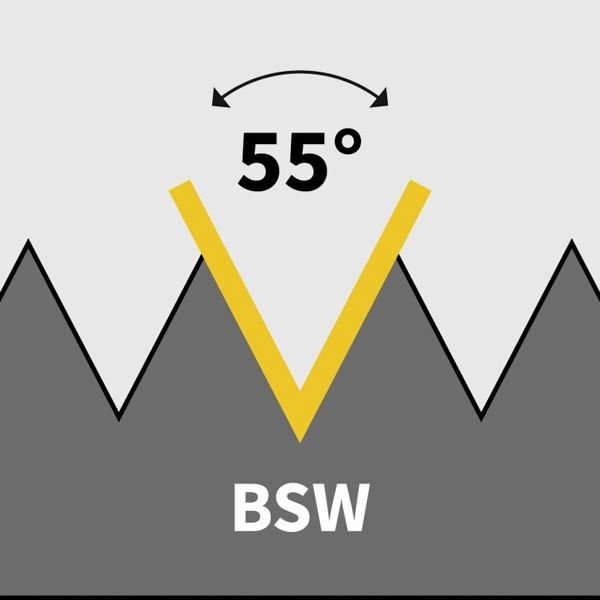

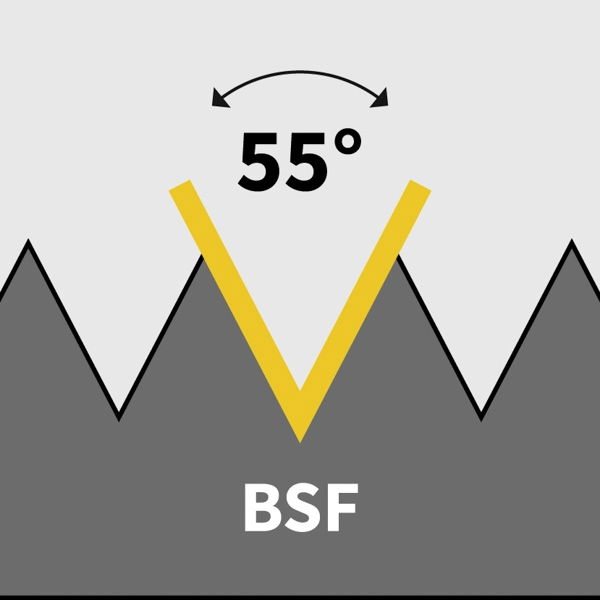

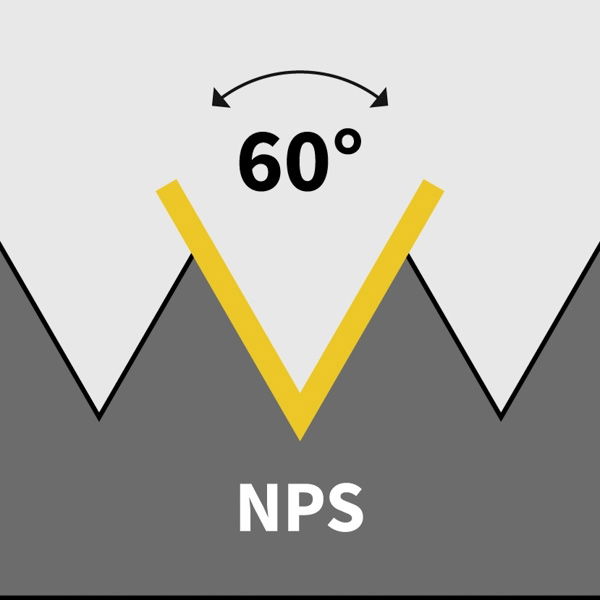

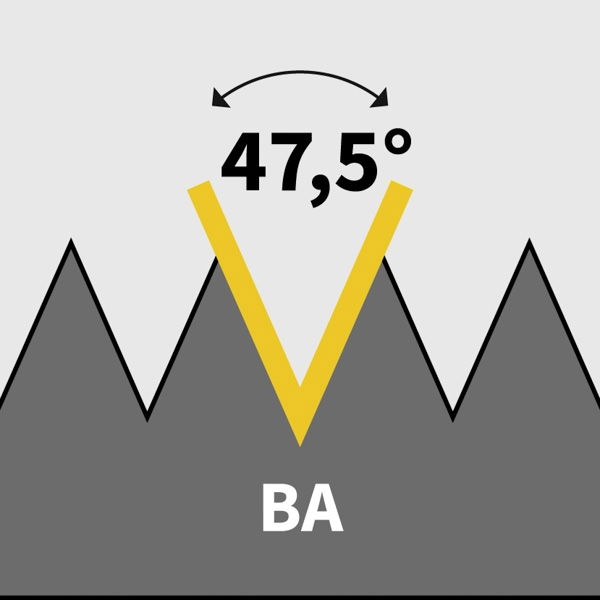

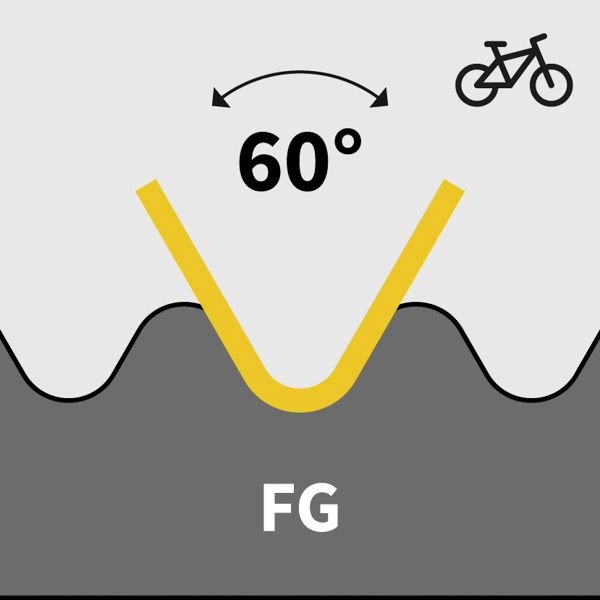

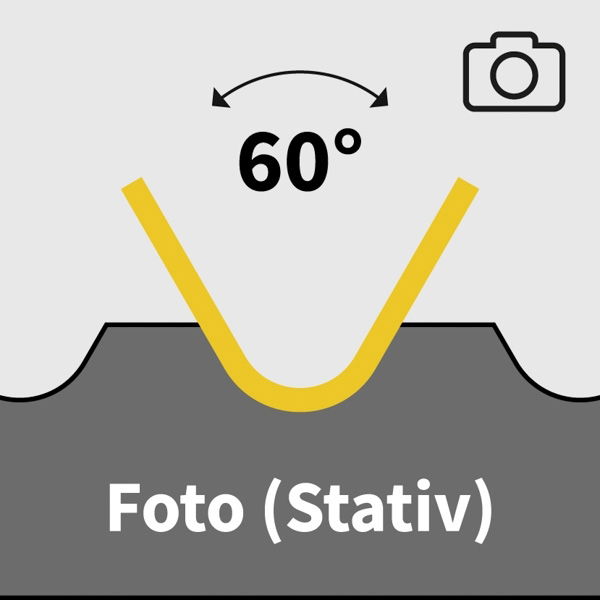

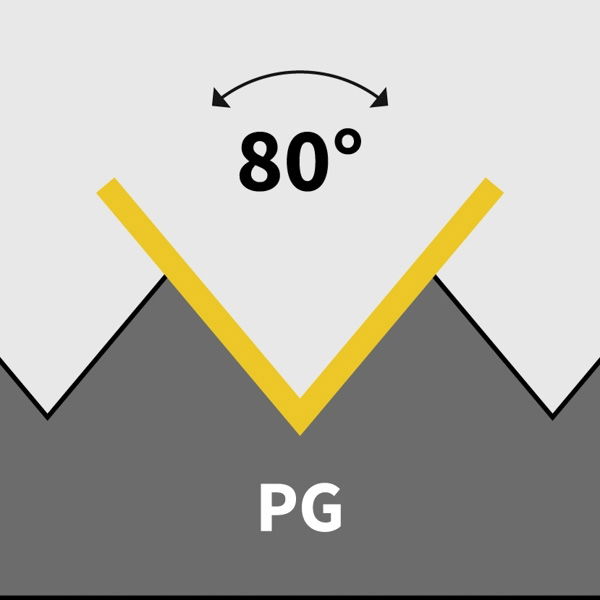

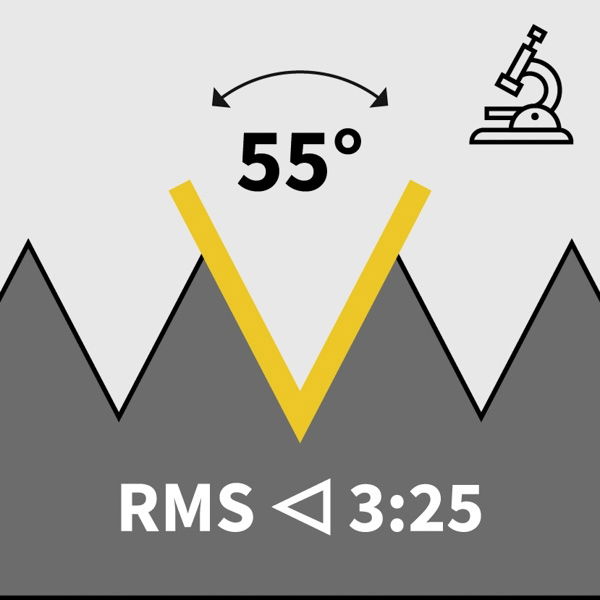

The thread angle of the thread profile refers to the angle included in the thread tip, i.e. from the ascending plane of the tip to the descending plane. For most thread standards in our shop, the thread angle is 60° and thus all sides in the thread pitch triangle are of equal length (equilateral triangle). This applies to all metric threads and all American fastening threads. However, the British threads (Whitworth) almost all have a more acute thread angle of 55° degrees.

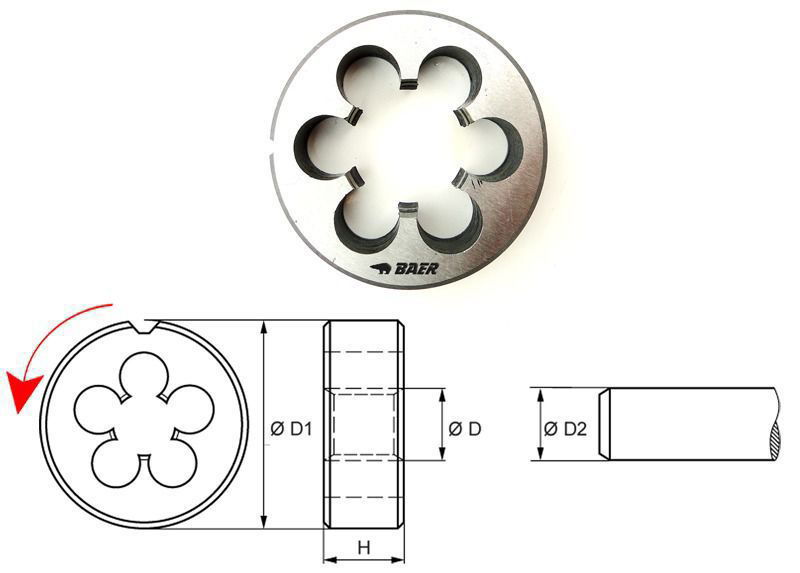

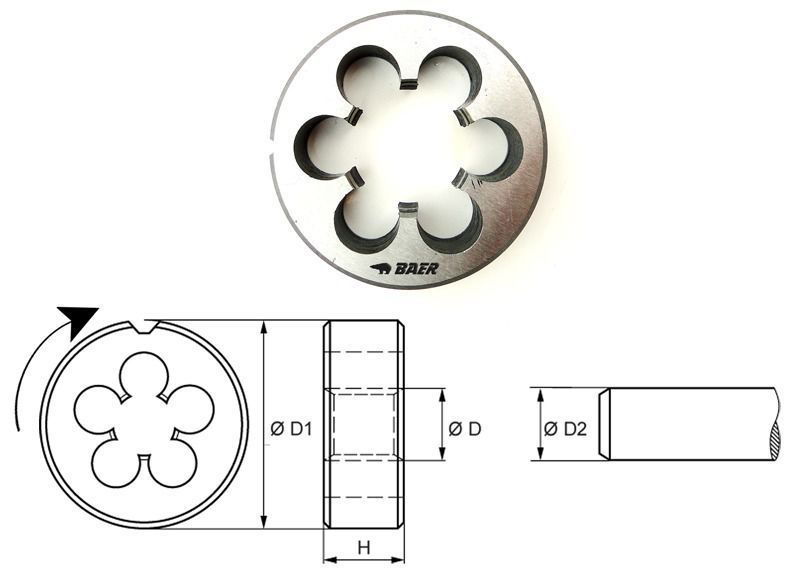

Right-hand thread and left-hand thread in thread standards

In most thread standards the right-hand thread is listed and the left-hand thread is not. The much more common right-hand thread is characterised by being tightened clockwise and untightened anticlockwise. In the case of the left-hand thread profile, this is completely reversed; here, the thread is tightened in an anti-clockwise direction (counterclockwise) and unscrewed in a clockwise direction. A classic example of this is the thread on bicycle pedals , where one pedal has to be fastened clockwise, but the other pedal clockwise.

The thread dimensions according to the standard, i.e. the Dimensions for the diameter, pitch and thread angle are not affected by whether the thread is a right-hand thread or left-hand thread.

Special thread standards, thread types and thread profiles at BAER

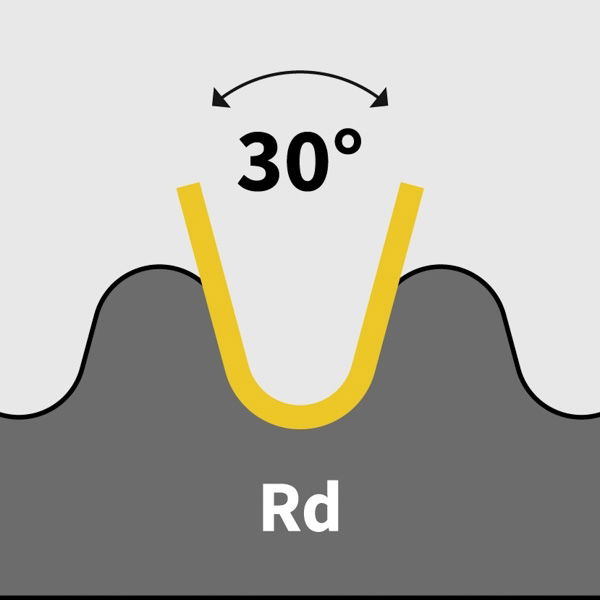

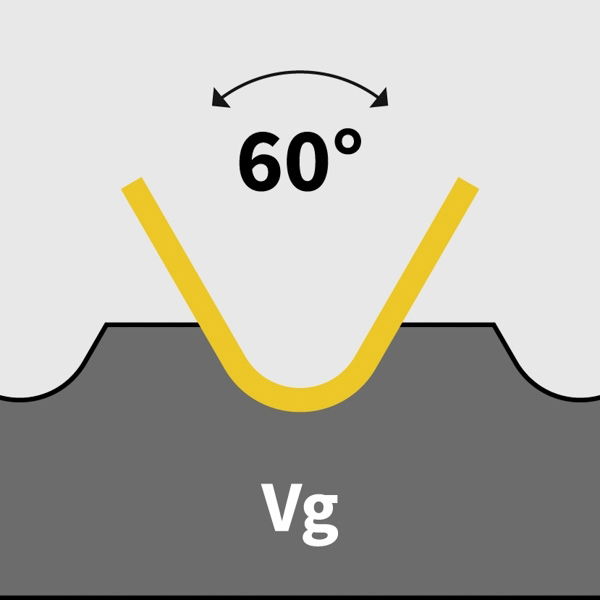

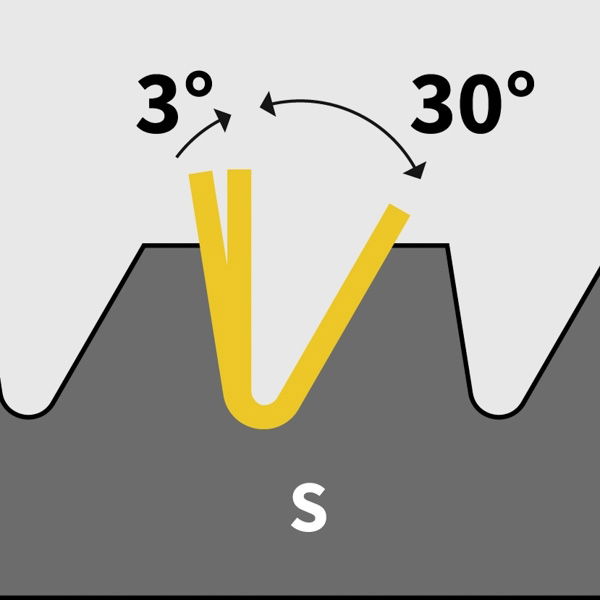

There are thread profiles that differ considerably from the usual pointed profiles for fastening threads. For example, there is the buttress threads, the thread tips of which form a very steep and a very flat side like a saw tooth and can thus transmit a very high load on one side. There are also several standards on the knuckle thread with the most common standard DIN 405, whose thread profile is not pointed, but round and is therefore popular for.

The thread profile is not pointed but round and is therefore often used for screwed connections that should not become sluggish due to dirt and grime.

The flank angles also vary widely, for example the steel conduit thread has a large thread angle of 80° and is therefore relatively flat in the thread height.

Thread standards from BAER for many applications

At BAER Tools you will find the right thread standard for every application thanks to our wide range of products. We are always up to date and are happy to pass on our expertise to you. So don't hesitate to contact us - we will support you at any time and offer you professional advice on thread standards & Co. Let the excellent BAER quality convince you and benefit from durable tools and accessories!