In stock

Express shipping available

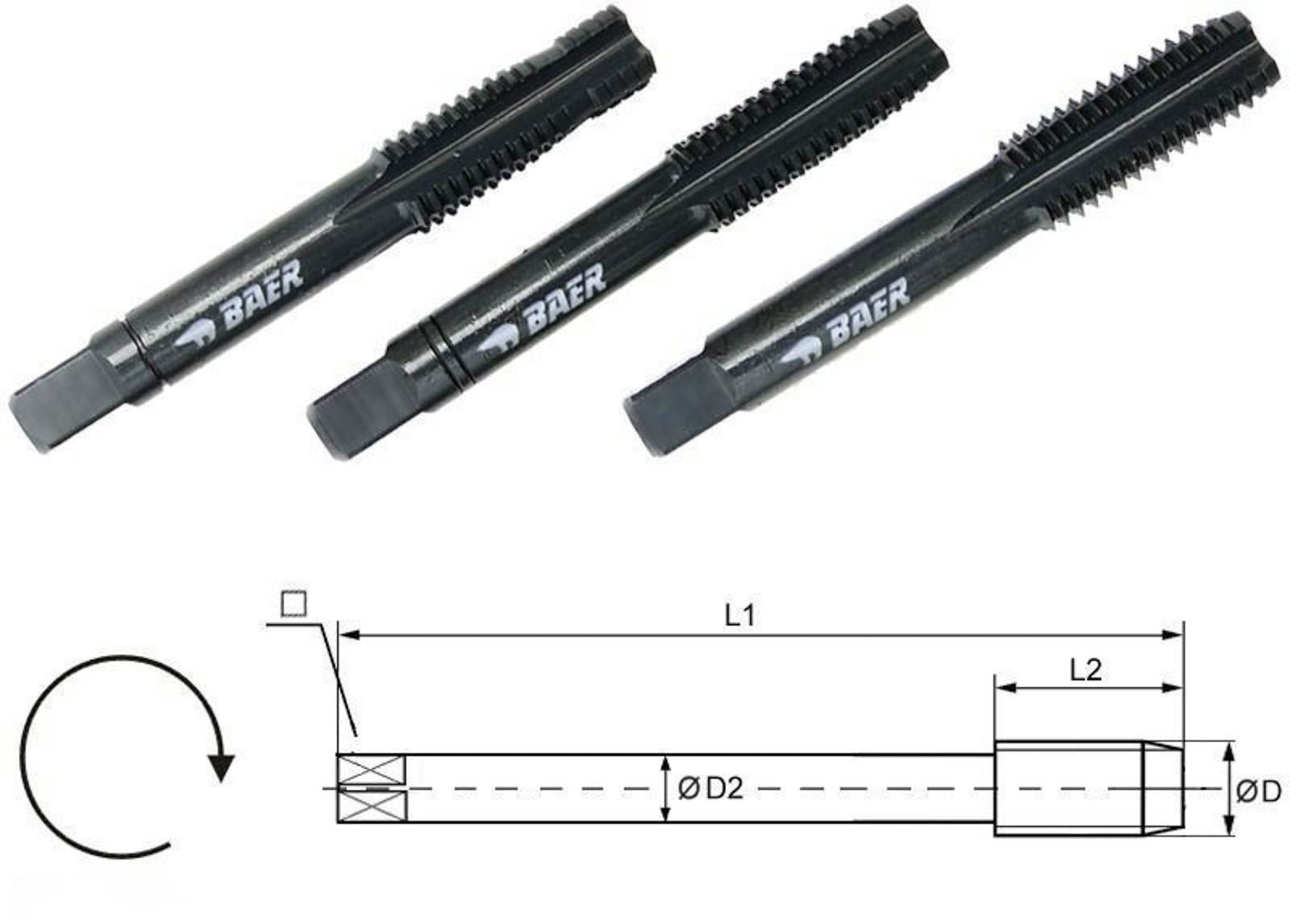

BAER HSSE VAP Hand Tap Set (3pcs.) M 10 x 1.5 - for Stainless Steel

The hand tap set consists of three taps and allows you to cut a finished thread with significantly reduced risk of breakage. The advantage of three-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) has a guide nose and ensures that perpendicular threads are always cut, even in the trickiest places. It is (marked with one ring) and removes 65 percent of the thread profile, while the intermediate tap (No. 2) (marked with two rings) removes 85 percent. Pre-cutting and reworking with the intermediate tap (No. 2) bring the thread into shape. In the last step, the finishing tap (No. 3) is used, which has no ring marking. Only this cuts the full and usable thread at the end. The division of labour between the three screw tap makes it easier to cut a straight and clean thread by hand.

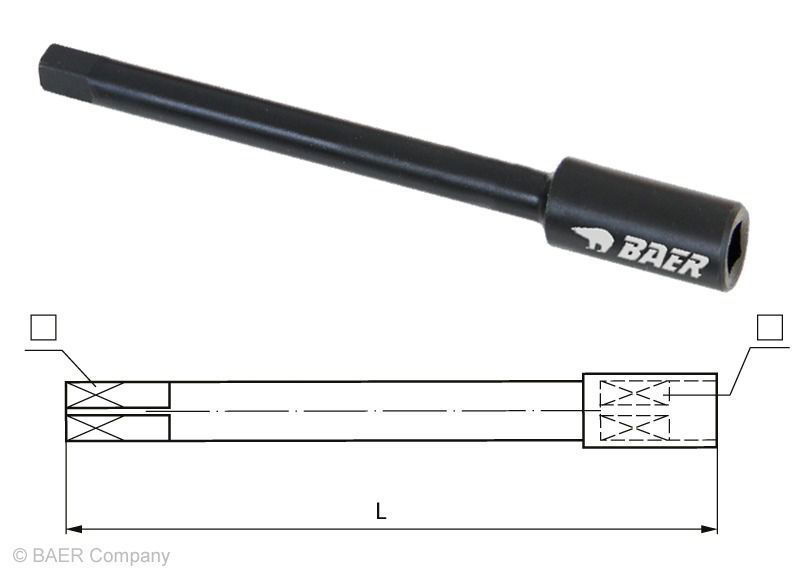

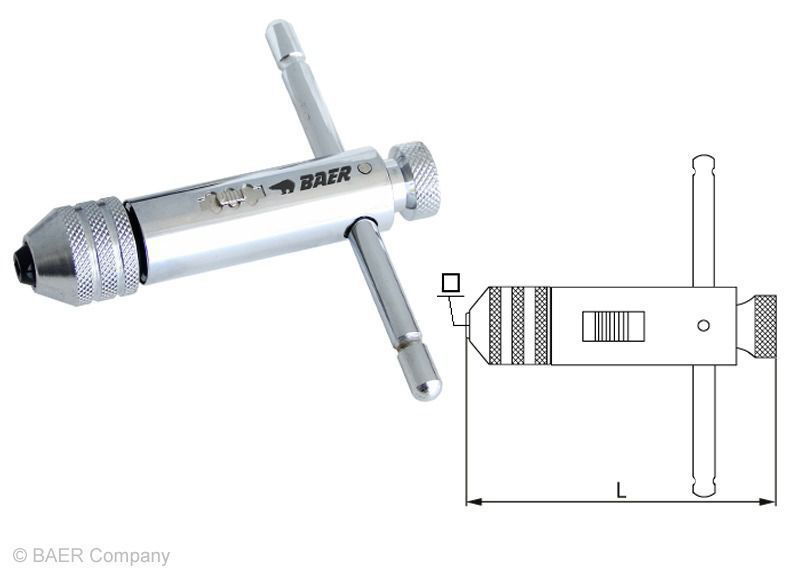

Compared to the machine tap, the hand tap has a short shank. This allows you to cut internal thread by hand without jamming and can be operated with tap wrenches, tool ratchets or other holding tools with square drive.

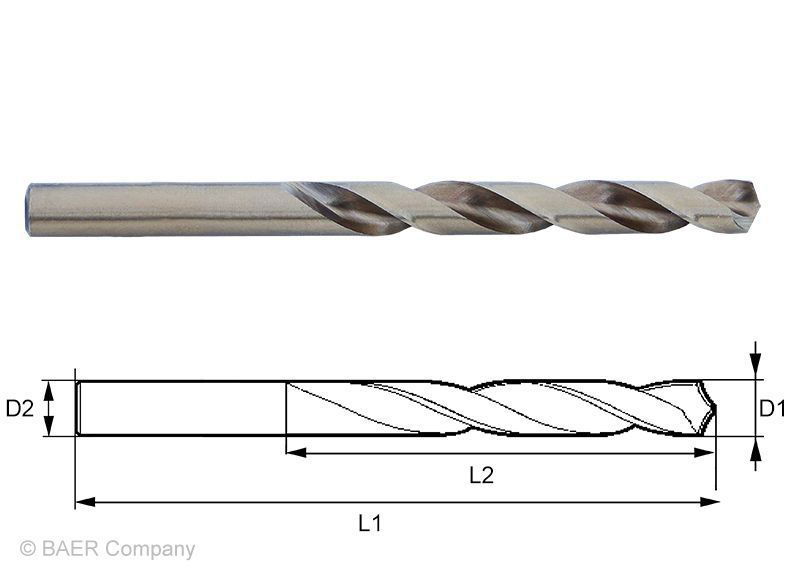

The thread can be cut in a pre-drilled core hole.

Due to the short chamfer of the finish tap, the hand tap set can be used reliably and universally for through holes and blind holes.

As a rule, three-piece hand taps- sets are used for regular threads with coarse pitch, as the thread profile area is larger than for fine threads and the force effects on the taps are greater.

Dimensions

| Diameter |

10 |

|---|---|

| Nominal diameter in inches |

0,394 |

| Nominal diameter in mm |

10 |

| Pitch |

1,5 |

| Pitch in mm |

1,5 |

| Dimension |

M 10 x 1,5 |

| Square |

5,5 mm |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Hand tap sets |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

DIN 352 |

| Tensile strength at room temperature |

up to 1400 N/mm² | 44.5 HRC |

| Material |

HSSE VAP |

Technical information – Screw taps

8.5 mm

Through hole and blind hole up to 2 x D

Form C straight fluted

2-3 threads

Rarely occurs. Chips remain in flutes.

External cooling and lubrication

HSSE VAP

up to 1400 N/mm² | 44.5 HRC

ISO2/6H

Applications

- Wear resistant steels up to 1400 N/mm²

- High alloy steels

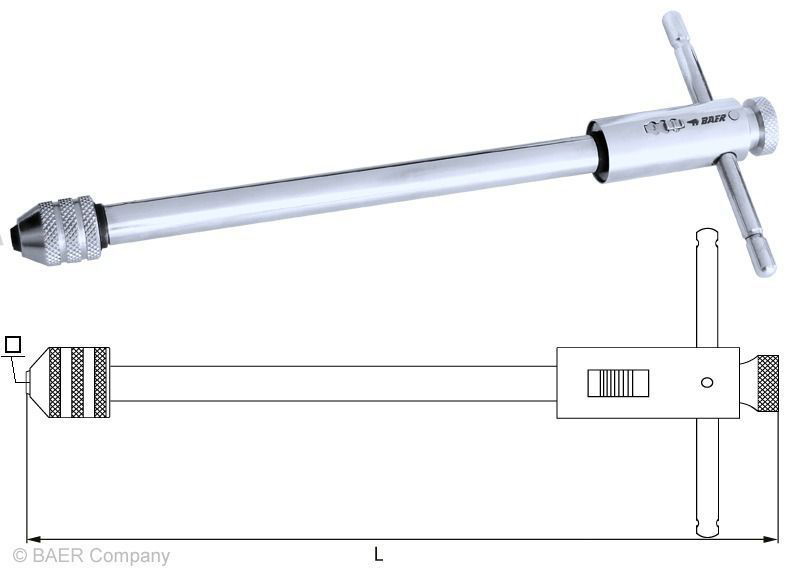

Technical drawing

| D1 |

M 10 x 1,5 |

|---|---|

| D2 |

7 mm |

| L1 |

70 mm |

| L2 |

24 mm |

| Diameter |

10 |

| Square |

5,5 mm |

Application – Sample materials

| Rust / acid-resistant steels | |

|---|---|

| 1.4105 | X 6 CrMo S 17 |

| 1.4305 | X 8 CrNi S 18-9 |

| 1.4301 | X 5 CrNi 18-10 |

| 1.4541 | X 6 CrNiTi 18-10 |

| 1.4057 | X 17 CrNi 16-2 |

| 1.4112 | X90 CrMoV 18 |

| 1.4006 | X 12 Cr 13 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17 CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck 22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck 45) |

| Pure titanium | |

|---|---|

| 3.7035 | Ti 99.4 / Ti Gr.2 |

| 3.7065 | Ti 99.2 / Ti Gr.4 |

| Quenched and tempered steels alloyed | |

|---|---|

| 1.1133 | 20Mn5 |

| 1.5710 | 36NiCr6 |

Further information

Safety instructions

Login