M12 or G1/4″: Taps for different thread types

The thread type is the second major factor that influences the selection of a tap. We have summarised the most important

information about the different thread types in this overview.

In Europe, the ISO standard thread according to DIN 13-1 or the ISO fine thread according to DIN 13-2

to 13-11 is usually used for screw connections. For the production of pipe connections, on the other hand, the Whitworth Pipe Thread is used, which you can recognise by the abbreviation G at

. The tables on our site will help you find your way around and select the right

thread size.

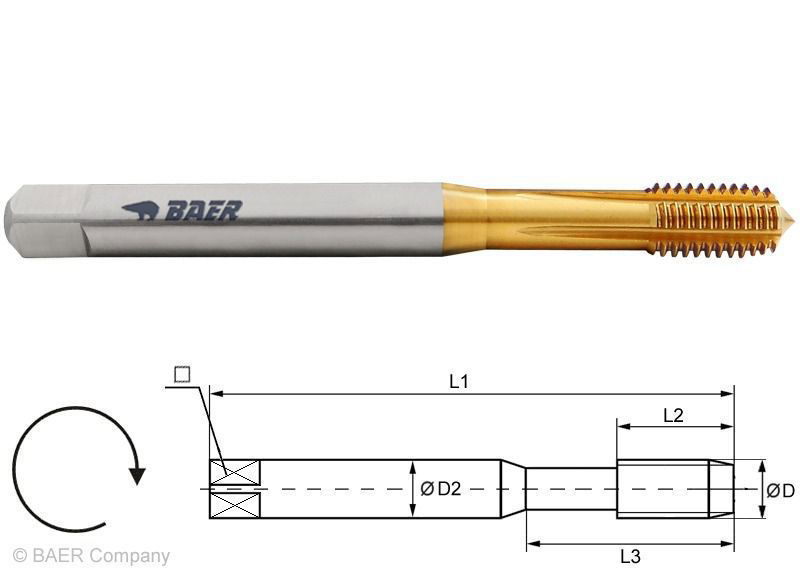

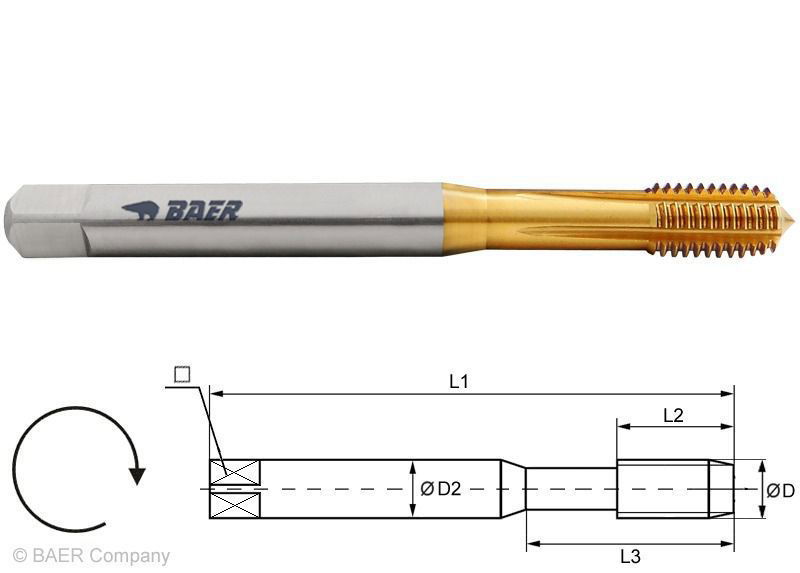

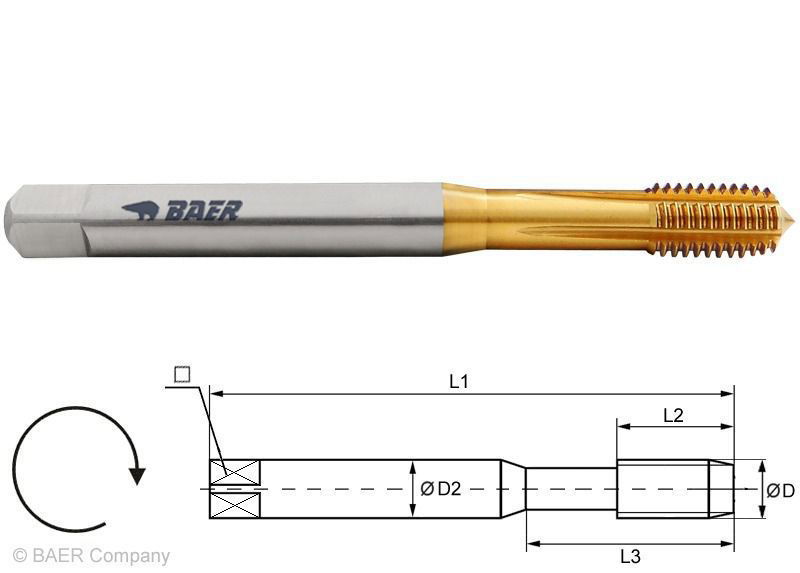

From the tip to the shank: This is how a tap is constructed

Even though the cutting cases can be very different, the structure of the tap is always very similar.

Geometries on the tap

Several Dimensions are summarised under this designation, which together result in the thread profile. These include

the nominal dimension, which is usually identical to the largest thread diameter, the thread pitch and the angles on

the cutting surfaces. For metric threads, the pitch is the distance between two thread tips. For

inch threads, this refers to the number of threads per inch.

The thread is not fully formed directly at the head of the tap, but only reaches its final shape after a few

threads. This area is known as the gate. A distinction is made between six

different Tap Chamfer forms from A (long form with 6 to 8 threads) to F (extremely short form with 1 to 1.5 threads).

Groove shapes

The groove shapes are decisive for chip removal, which in turn is influenced by the type of core hole.

Blind holes end in the component, so the chip must be removed backwards against the cutting direction. This

is achieved using right-hand helical flutes. In through holes, the chip can exit the bottom of the hole; here

straight flutes or left-twisted spiral flutes are used.

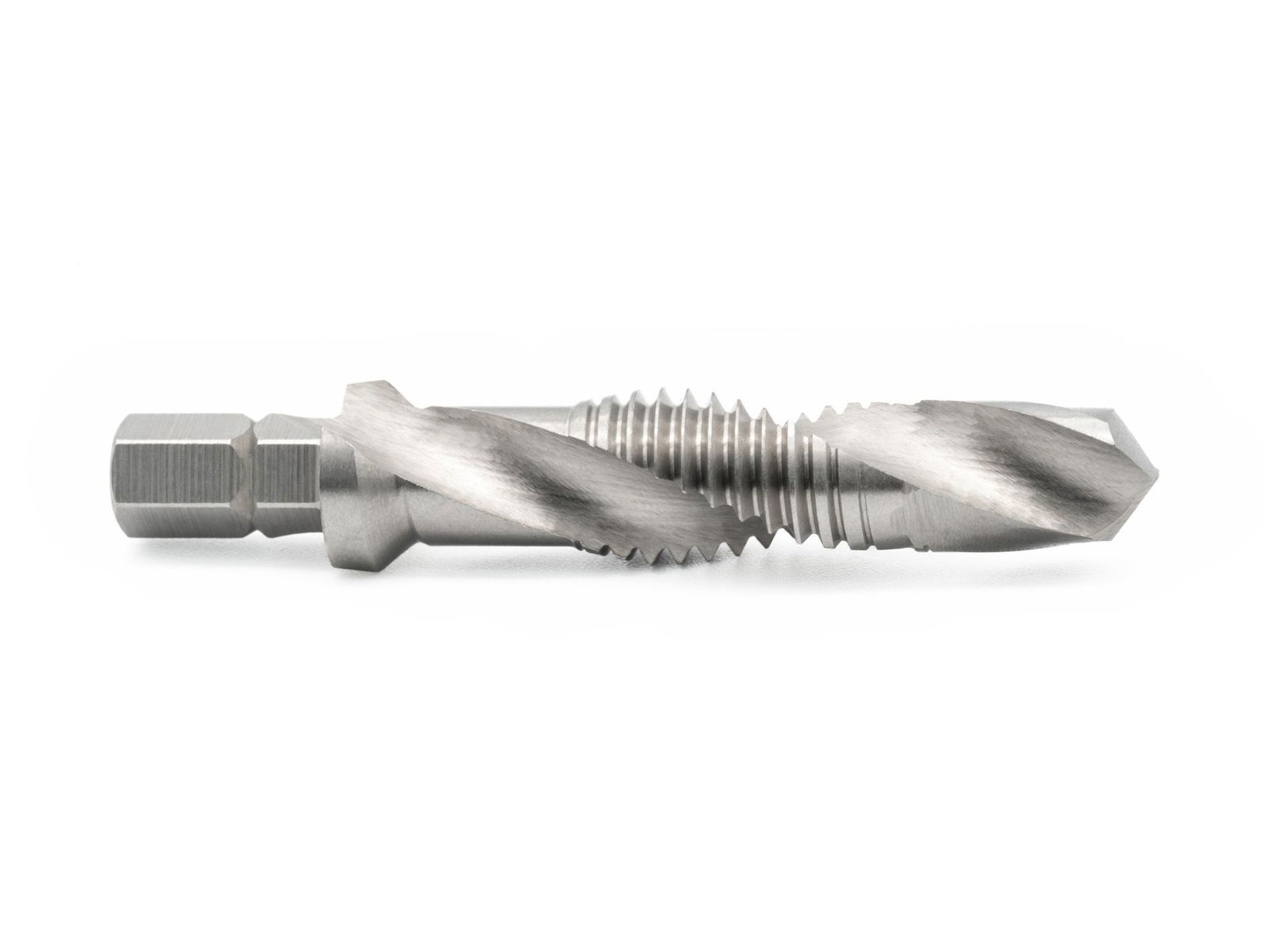

Shank shapes

A distinction is made between a reinforced shank with a diameter greater than the

nominal diameter of the thread and a stepped shank with a diameter smaller than the nominal dimension. Usually

the end is square, but you will also come across hexagonal shanks on bit taps.

HSS and more: Taps for professionals are made from this material

It is not only the material of the workpiece that is decisive, but also that of the tool. The base material and

post-treatment ensure stable cutting edges, smooth surfaces and smooth

chip removal for all applications.

Material

High-quality threading tools are almost always made from a special steel known as

high-speed steel or HSS for short. The

characteristics of this material can be adapted to the

challenges of thread cutting by varying the proportion of alloying elements. The abbreviation HSSE, for example, indicates a high cobalt content,

which increases hardness, hot hardness and tempering resistance when working with hard metal.

Coatings and Surface treatments

In addition to the base material, coatings and further treatments also offer the possibility of influencing the

characteristics of drills. Such a coating is necessary for certain metals such as aluminium,

in order to facilitate the removal of chips and create a thread that holds the gauge. A suitable

treatment also increases tool life.

Inside or outside? This is the difference between taps and cutting die

Taps are used to cut an internal thread. A cutting die in conjunction with a

tap holder helps you to apply an external thread to a bolt, for example on threaded rods or

screws.

This is how it works: You need to pay attention to this when using a tap

The production of a thread begins with the core hole diameter. It is best to read the correct core hole diameter from

a table or calculate it using the rule of thumb. Then use a core drill to create the required

hole. When creating an external thread with the cutting die, the bolt diameter is of similar importance.

A countersink is useful for countersinking, which makes tapping easier. Cutting oil or another

lubricant should also never be missing when using the tap and cutting die.